Template climbing falling preventing system

An anti-falling and anti-falling technology, applied in the direction of formwork/template/work frame, house structure support, house structure support, etc., can solve the problems of failure of anti-fall device, high labor intensity of workers, casualties from climbing frame falling, etc. Easy to process and manufacture, efficient to prevent falling, and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

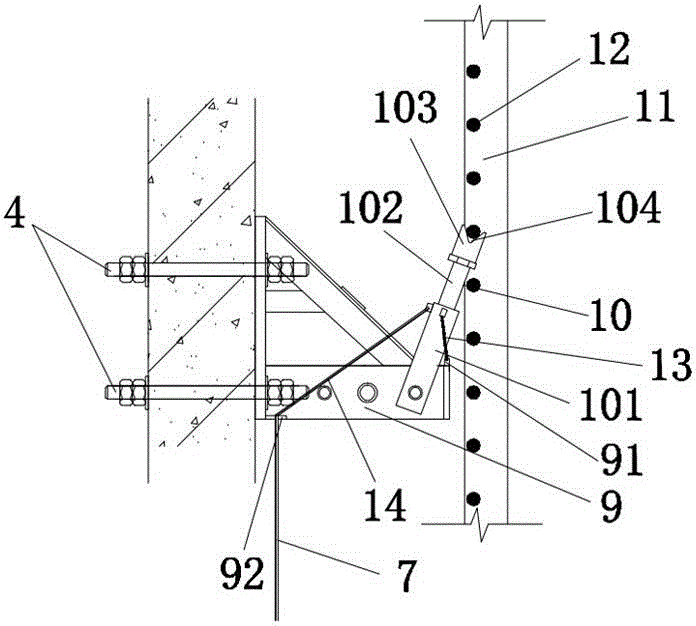

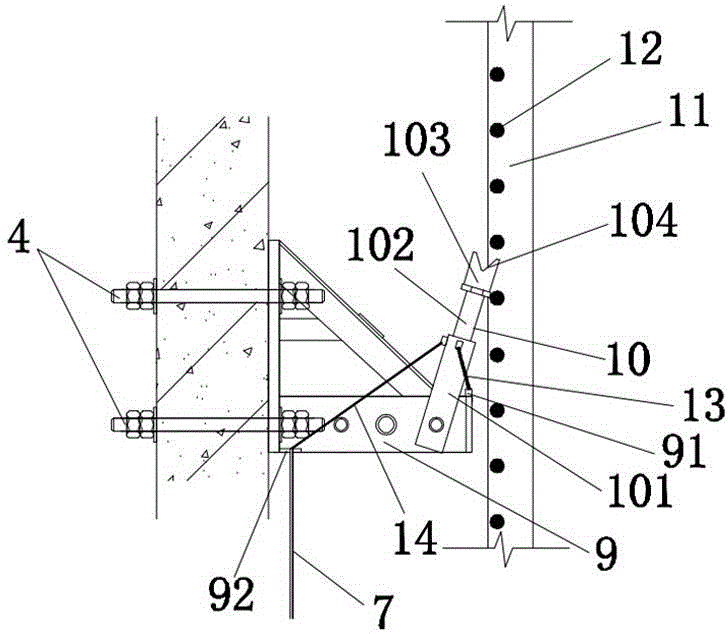

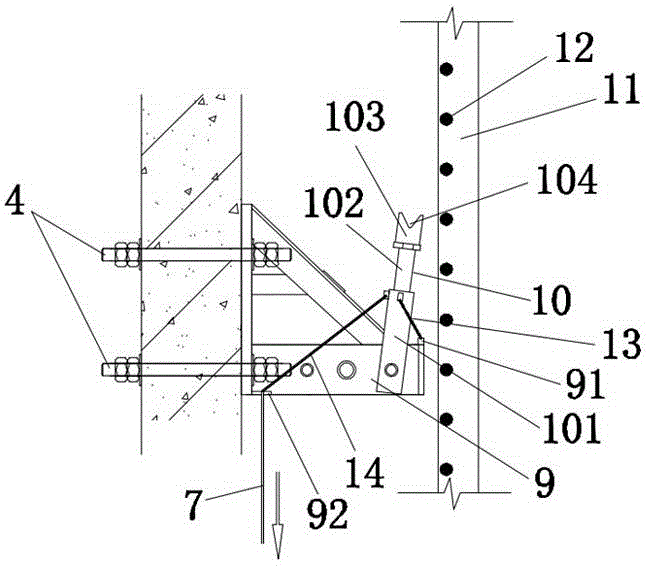

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0025] refer to Figure 1 to Figure 9 , the embodiment of the present invention provides a formwork climbing anti-fall system, including a fall prevention device. On the external wall of the object or the frame beam, the front end of the lifting suspension seat 1 is provided with a hanger screw rod, and the hanger screw rod includes a vertical pull rod 21 and a suspension hook 22. The vertical pull rod 21 is located above the suspension hook 22. The upper end is equipped with a hollow cylinder 23, and the first spring 5 is arranged in the hollow cylinder 23. The upper end of the vertical pull rod 21 passes through the lifting suspension seat 1 and the first spring 5 and stretches out the top of the hollow cylinder 23. 23 top is provided with top cover 24, and top cover 24 top is provided with the nut 25 that is screwed with the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com