A hand-held automatic cable tie tool

A hand-held, automatic technology, applied in the direction of strapping materials, strapping machine parts, packaging, etc., can solve the problems of high labor intensity and low work efficiency, reduce labor intensity, improve efficiency, tension force and cutting retention The effect of uniform tail length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

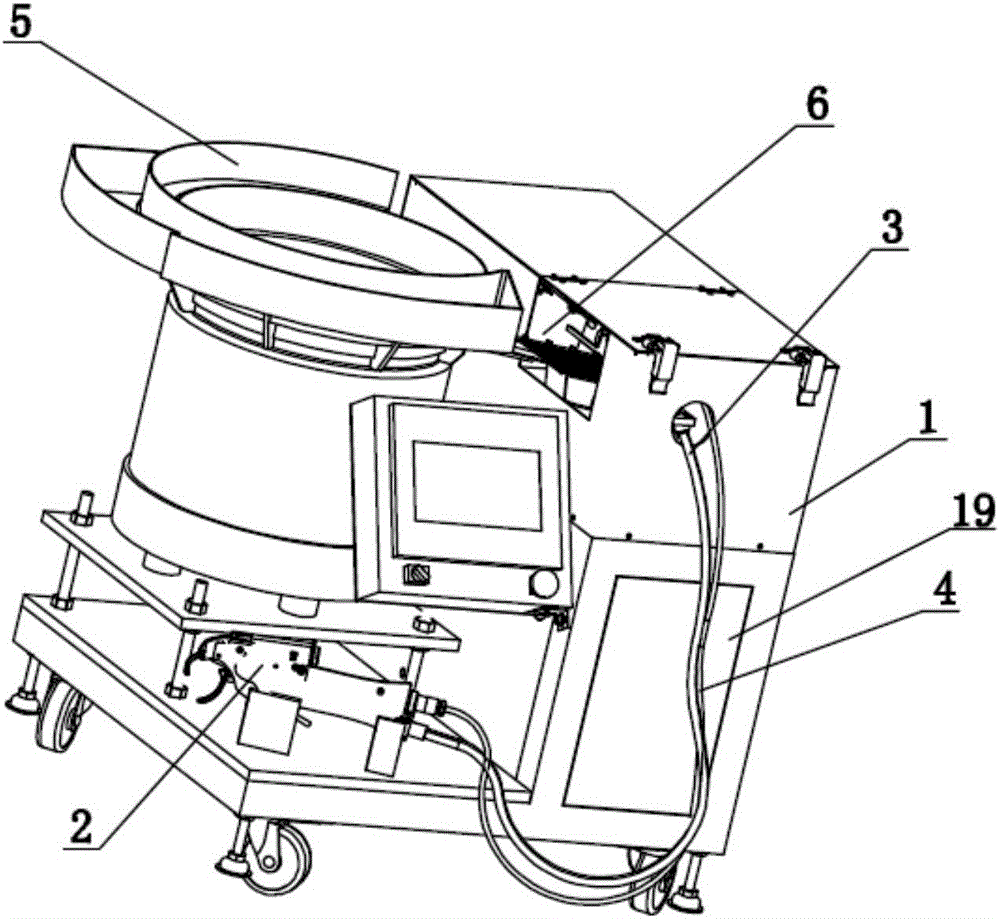

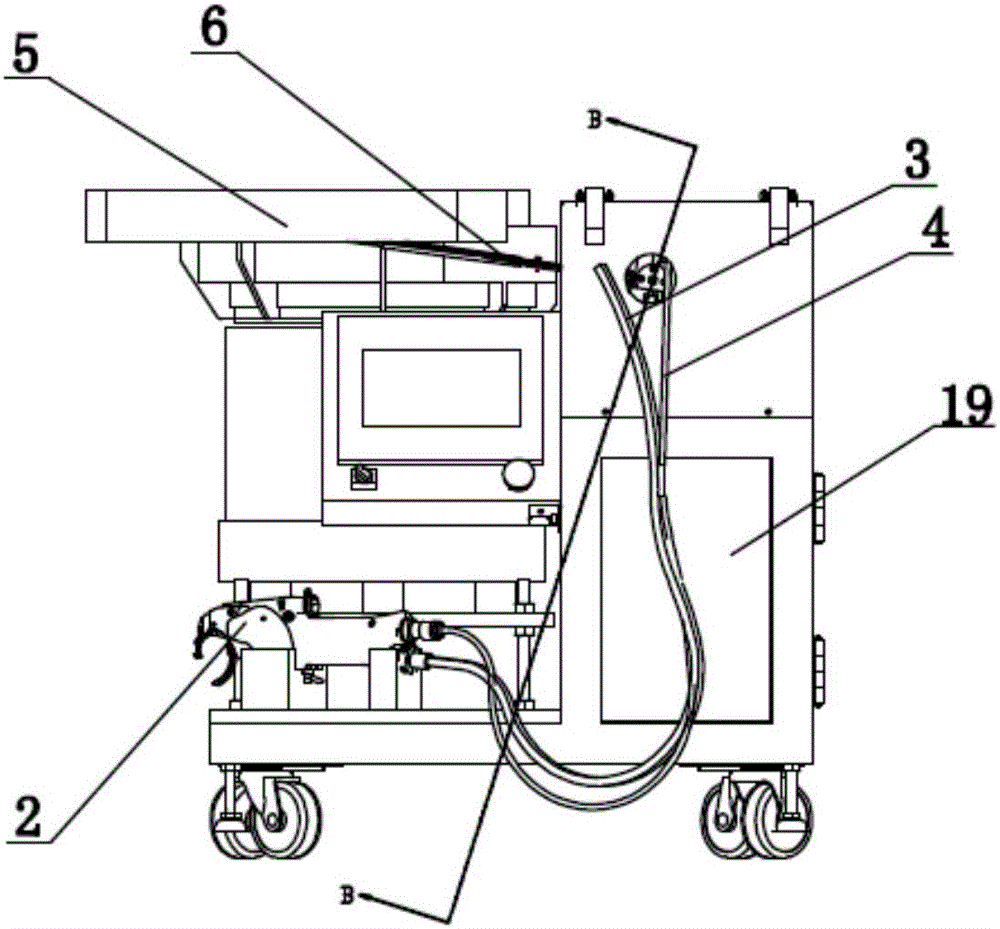

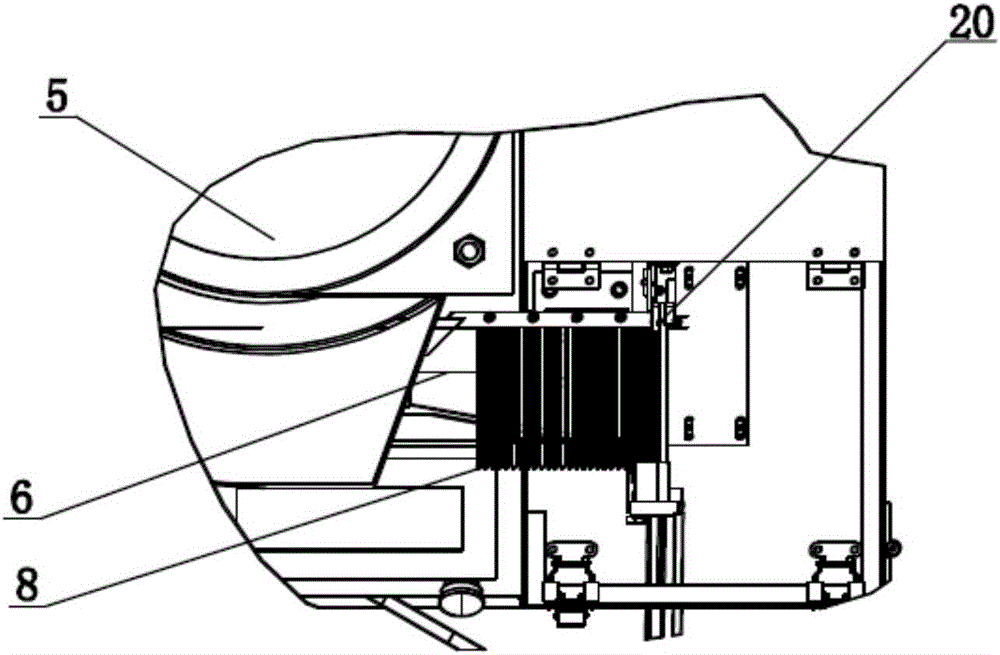

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Picture 8 , Picture 9 , Picture 10 , Picture 11 , Picture 12 Shown: a hand-held automatic cable tie tool, including a host 1, a gun head 2, a feeding tube 3, and a data line 4. The host 1 is connected to the gun head 2 through the feeding tube 3 and the data line 4, so The host 1 includes a pusher cylinder 11, a pusher cylinder seat 12, a pusher block 13, a guide block 15, a feeding pipe connector 16, a valve 17, a valve cylinder 18, an electric and air control system 19, below the host 1 An electric and air control system 19 is provided, the feeding pipe 3 is connected to the upper right end of the host 1, and a valve 17 is provided below the port where the feeding pipe 3 is connected to the host 1;

[0037] A valve cylinder 18 is provided below the valve 17, a feeding pipe connecting piece 16 is arranged above the valve 17, a guiding block 15 is arranged behind the feeding pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com