Buffers with release devices for rail vehicles

A technology for rail vehicles and buffers, which is applied in the direction of buffers, transportation and packaging, railway car body parts, etc., and can solve the problems of lack of good guidance for detachment and deviation during detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

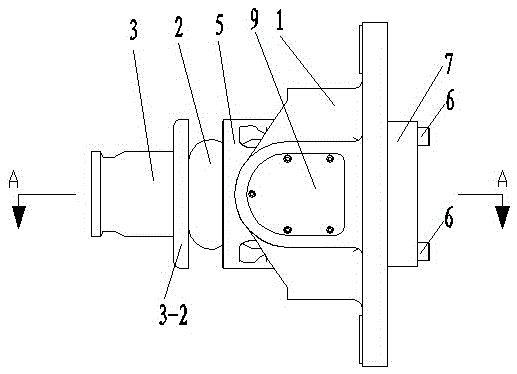

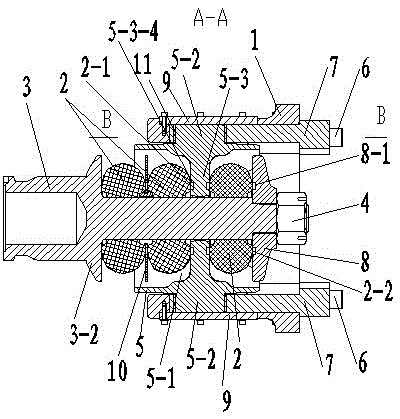

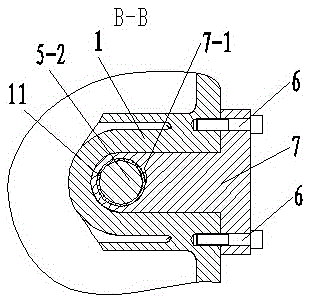

[0027] Such as Figure 1~7 As shown, a buffer with a detachment device for a rail vehicle includes a mounting base 1, more than two elastic bodies 2, a draw bar 3 and a locking member 4, the elastic body 2 is set on the draw bar 3, and through the lock The tightening member 4 is locked, and also includes a rotating shaft cylinder 5, a breaking bolt 6 and a guide block 7. The mounting base 1 is provided with a first mounting hole 1-1, and the rotating shaft cylinder 5 is located in the first mounting hole 1-1. The inner wall of the first installation hole 1-1 of the mounting seat 1 is provided with a guide groove 1-2, and the guide block 7 is provided with a shaft hole 7-1, and the guide block 7 is slidingly connected with the guide groove 1-2, and the guide block 7 is fixedly connected with the end face of the mounting seat 1 by breaking t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com