Stamp-pad ink mechanism and rolling printing stamping device with stamp-pad ink mechanism

A printing ink and stamp technology, applied in the field of roll stamping and stamping devices, can solve problems such as inability to ensure uniformity, shedding, poor reliability, etc., and achieve the effect of ensuring the quality of stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

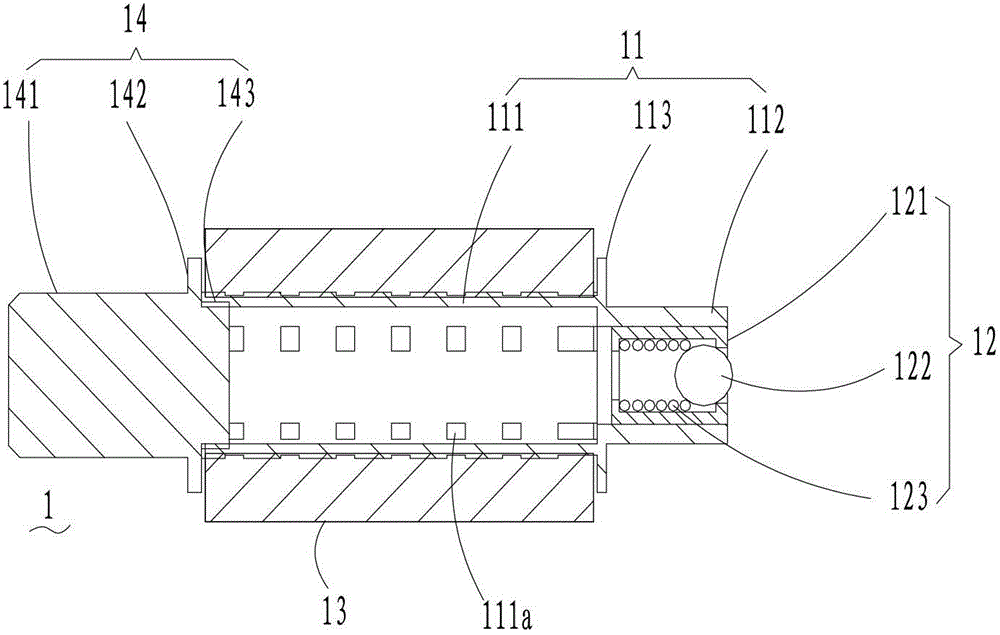

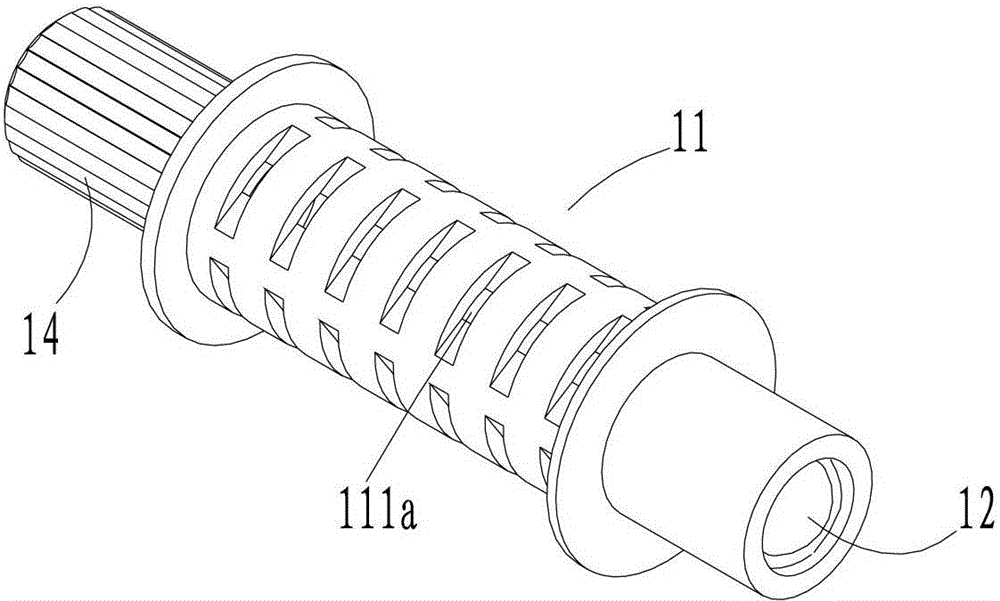

[0055] figure 2 It is a structural sectional view of an ink printing mechanism according to an embodiment of the present invention, image 3 It is a schematic diagram of a partial structure of an ink printing mechanism according to an embodiment of the present invention. Such as figure 2 , image 3 As shown, the ink printing mechanism 1 includes an oil filling assembly and an oil application roller 13 , wherein the oil application roller 13 is used to apply ink to the surface of the stamp, and the oil injection assembly communicates with the oil application roller 13 for filling the oil application roller 13 with ink.

[0056]The oiling roller 13 is in the shape of a sleeve and has a set inner diameter and outer diameter. The length of the oili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com