Multifunctional vulcanizing machine

A vulcanizing machine and multi-functional technology, which is applied in the field of vulcanizing machines, can solve the problems that the heating unit cannot be controlled independently, affects the vulcanization effect, and is prone to errors, etc., and achieves the effects of convenient control, guaranteed vulcanization effect, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

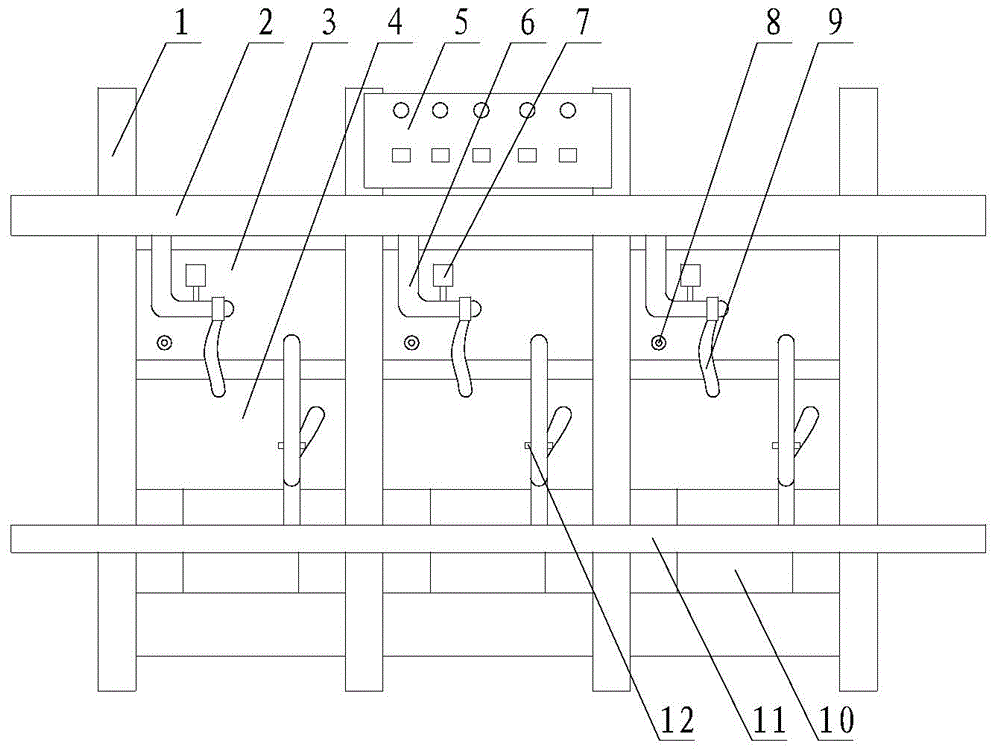

[0013] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0014] A multifunctional vulcanizing machine, comprising an outer frame 1, an upper heating plate 3, a lower heating plate 4, a hydraulic cylinder 10, a steam trap 12, a main air intake pipeline 2 and a main air outlet pipeline 11, and multiple heating units are installed on the outer frame , each heating unit is composed of an upper hot plate, a lower hot plate and a hydraulic cylinder, the upper hot plate and the lower hot plate are hollow structures, the upper hot plate is installed on the outer frame, the lower hot plate is connected On the outer frame, the above is a known technology, and will not be repeated here.

[0015] The innovation of the present invention is that the inlets of the upper hot plate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com