Filling device for activated carbon plates in filter absorbers

A filter absorber and activated carbon plate technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of production pollution, large gap between activated carbon particles, and decreased activated carbon layer, so as to purify the production environment and improve the Production efficiency, the effect of avoiding vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

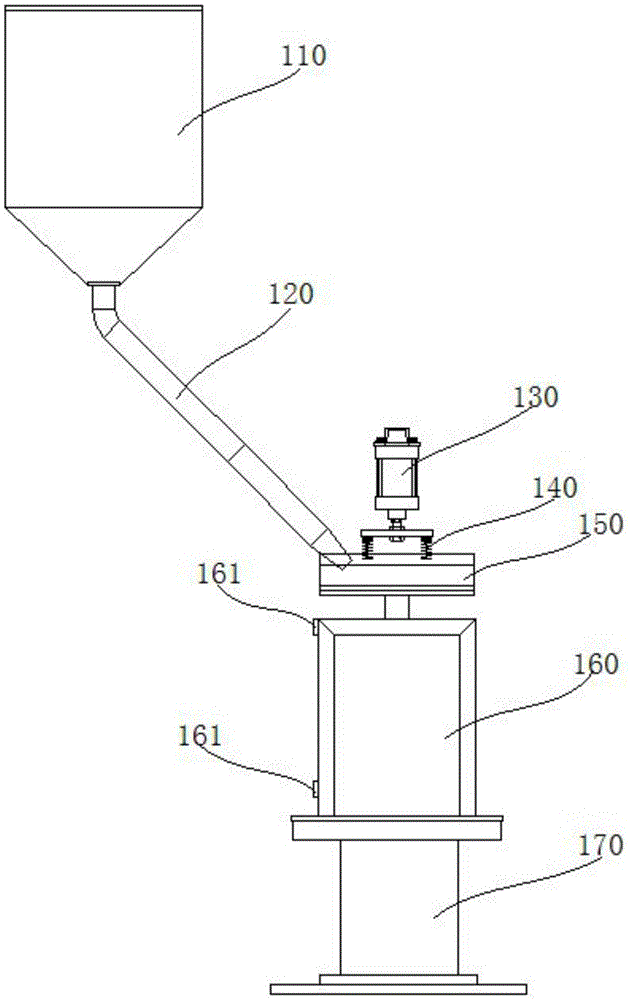

[0016] Such as figure 1 As shown, it is a filling device for activated carbon plates in a filter absorber in this implementation, including a storage tank 110, a hopper 150, a support frame 160 and a vibrating table 170, and a storage tank 110 and a hopper 150 are provided The feeding pipeline 120 and the hopper 150 are arranged on the support frame 160 with adjustable height, the support frame 160 is arranged on the vibration table 170, and the support frame 160 is provided with a clamping mechanism 161; the active carbon plate to be filled is provided on the vibration table 170 and the hopper 150 and can be clamped by the clamping mechanism 161.

[0017] A compression cylinder 130 is arranged above the hopper 150 , and the compression cylinder 130 can apply downward pressure to the hopper 150 through a damping spring 140 , and a valve is provided on the feeding pipeline 120 .

[0018] When the user uses the filling device for the activated carbon plate in the filter absorbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com