Looseness preventing diesel tank of diesel engine

A diesel engine, anti-loosening technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as poor firmness and difficult assembly, and achieve the effect of preventing loosening, reducing assembly difficulty and ensuring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

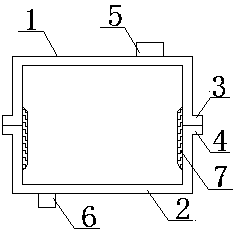

[0012] like figure 1 It is a schematic diagram of the present invention, a kind of anti-loose diesel engine oil tank, comprises upper box 1, lower box 2, upper joint 3, lower joint 4, oil inlet 5 and oil outlet 6, upper joint 3 and The oil inlet 5 is respectively located at the bottom and the top of the upper case 1, the lower joint 4 and the oil outlet 6 are respectively located at the top and the bottom of the lower case 2, and the upper case 1 passes through the joints of the upper joint 3 and the lower joint 4. The welding is integrated with the lower box body 2, and the upper box body 1 is provided with a positioning plate 7. The positioning plate 7 is an elastic metal plate. The top of the positioning plate 7 is fixed on the inner wall of the upper box body 1, and the lower part expands outwards and is inserted in the lower box body 2. The lower side of the positioning plate 7 is attached to the inner wall of the lower box body 2 .

[0013] A positioning plate 7 made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com