Apparatus and method for hermetically encapsulating a fuel rod or fuel rod section in a container

A fuel rod and airtight technology, which is applied to reactor fuel elements, lightweight protective containers, reduction of greenhouse gases, etc., can solve the problems of high operating costs and expensive structures, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

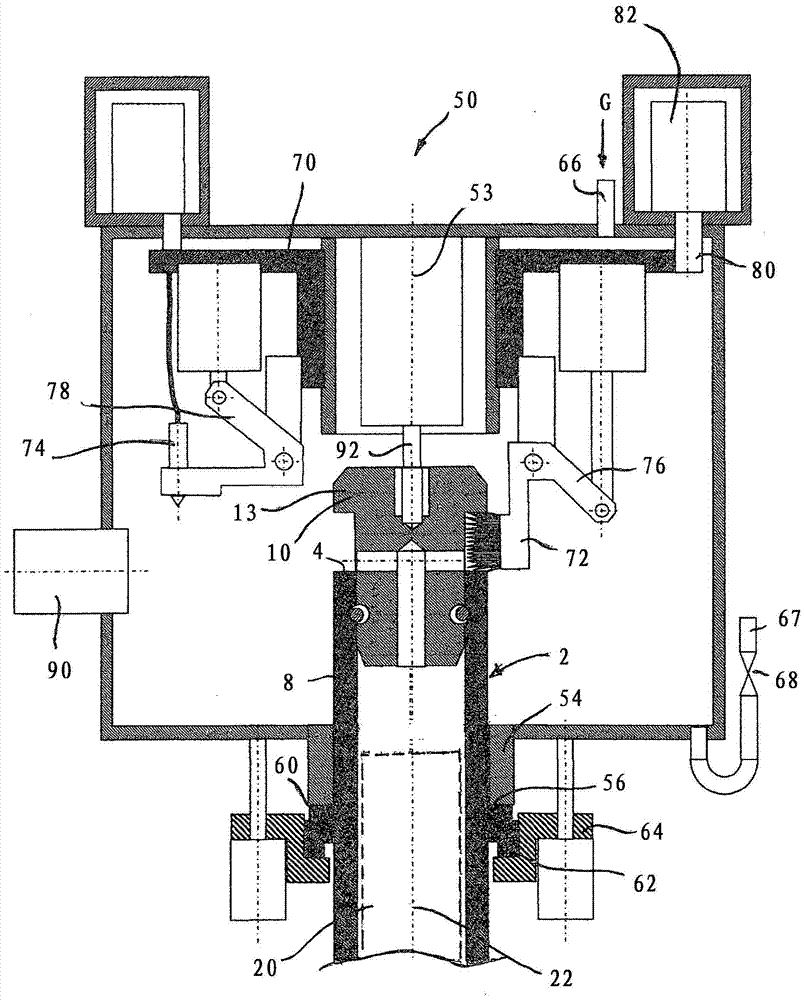

[0039] according to figure 1 The container 2 has a hollow-cylindrical container part 8 which is open on its end faces 4 and 6 . On the end faces 4 , 6 there is in each case a one-piece closure plug 10 partially pushed into the middle position. Each closing plug 10 has a head part 11 and a cylindrical shaft 12 whose outer diameter is only slightly smaller than the inner diameter of the container part 8 . The head part 11 has an annular surrounding flange 13 whose outer diameter corresponds to the outer diameter of the container part 8 . In the intermediate position, the closure plug 10 protrudes beyond the hollow-cylindrical container part 8 relative to its final position by an axial excess length s, so that the part of the shaft 12 lying below the head part 11 lies in the container part 8 outside.

[0040] Each closure plug 10 is provided with a channel 14 which, in this intermediate position, fluidly connects the interior space 15 with the exterior space 16 .

[0041] A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com