System used for controlling process specifications and full equipment lifecycle in electric power system

A full life cycle, power system technology, applied in electromagnetic radiation induction, data processing applications, instruments, etc., can solve problems such as potential safety hazards, poor accuracy, and affecting the safety and efficiency of power system operations, so as to ensure safe operation and comprehensive management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

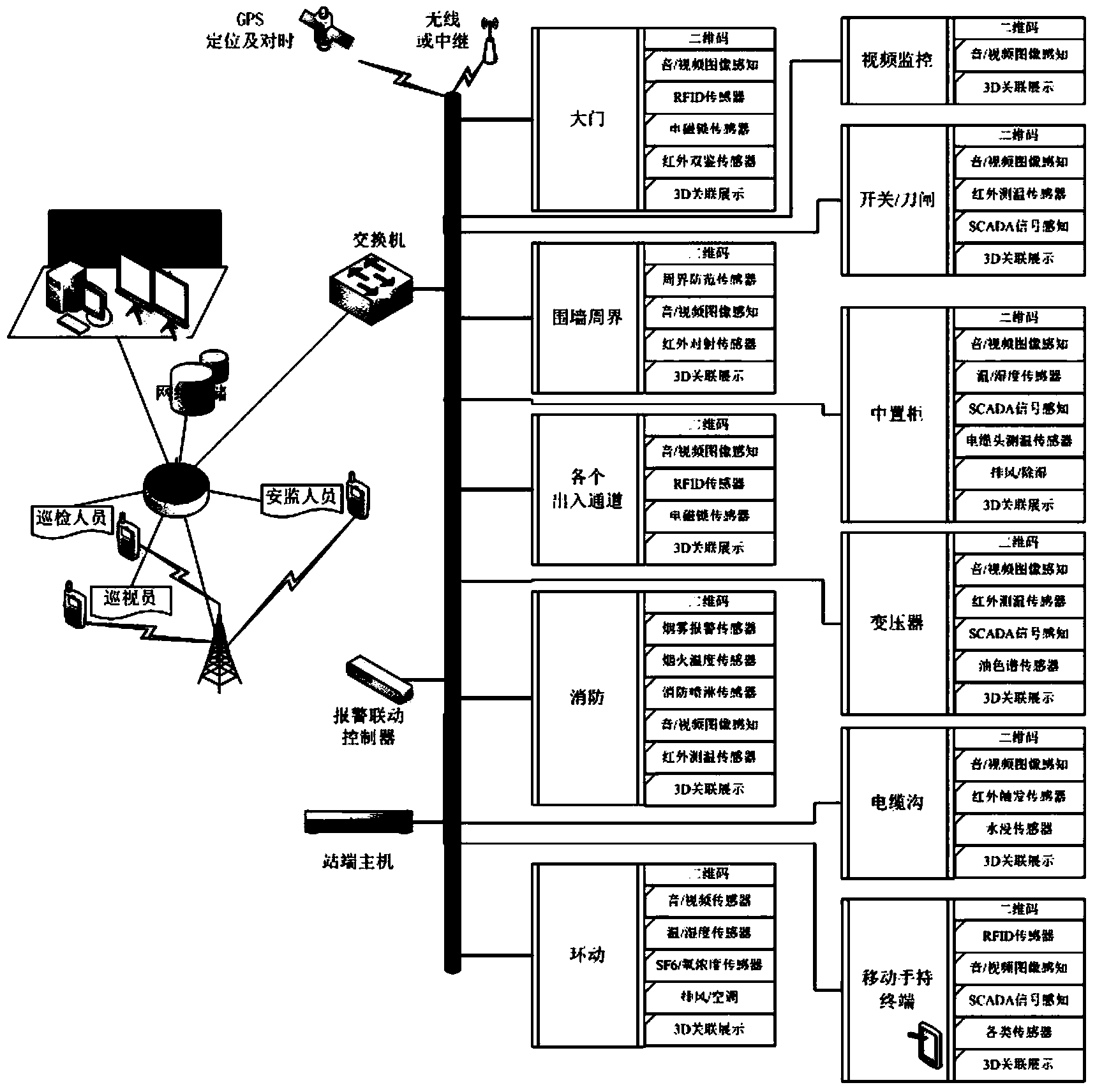

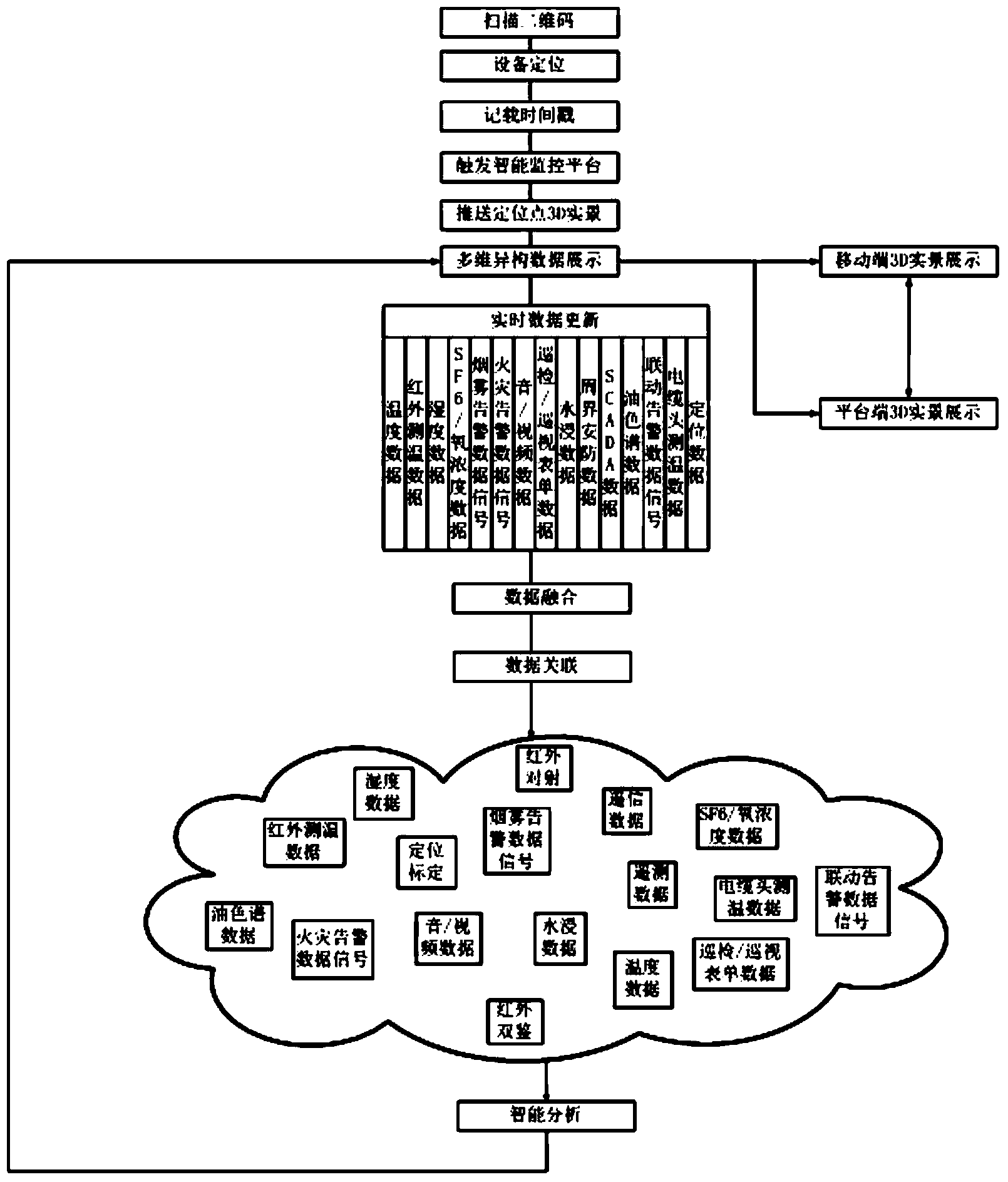

[0035] like figure 1 As shown, the system for controlling the process specification and the whole life cycle of equipment in the power system is based on the two-dimensional code technology and integrates VR intelligent visualization. The units controlled by the system in each substation include all or part of the following: the gate unit, the surrounding wall Boundary unit, channel unit, fire protection unit, circular unit, video surveillance unit, switch knife unit, central cabinet unit, transformer unit, cable trench unit, mobile handheld terminal; the controlled units are all connected to the station-end host in the substation , and connect with the intelligent monitoring platform and database through the switchboard, and connect the signal transceiver device with the mobile terminal outside the station. Therefore, real-time monitoring and data processing of each substation below can be carried out through the intelligent monitoring platform (main computer room), and tasks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com