Low temperature mixed insulating gas supplementing device

A technology of mixing insulating gas and gas, which is applied in the direction of gas/liquid distribution and storage, equipment loaded into pressure vessels, piping systems, etc., and can solve problems such as replenishment of difficult-to-mix gases, affecting normal operation of equipment, and gas-mixing ratio errors. To achieve the effect of accurate and reliable gas mixture ratio, convenient and fast inflation or replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

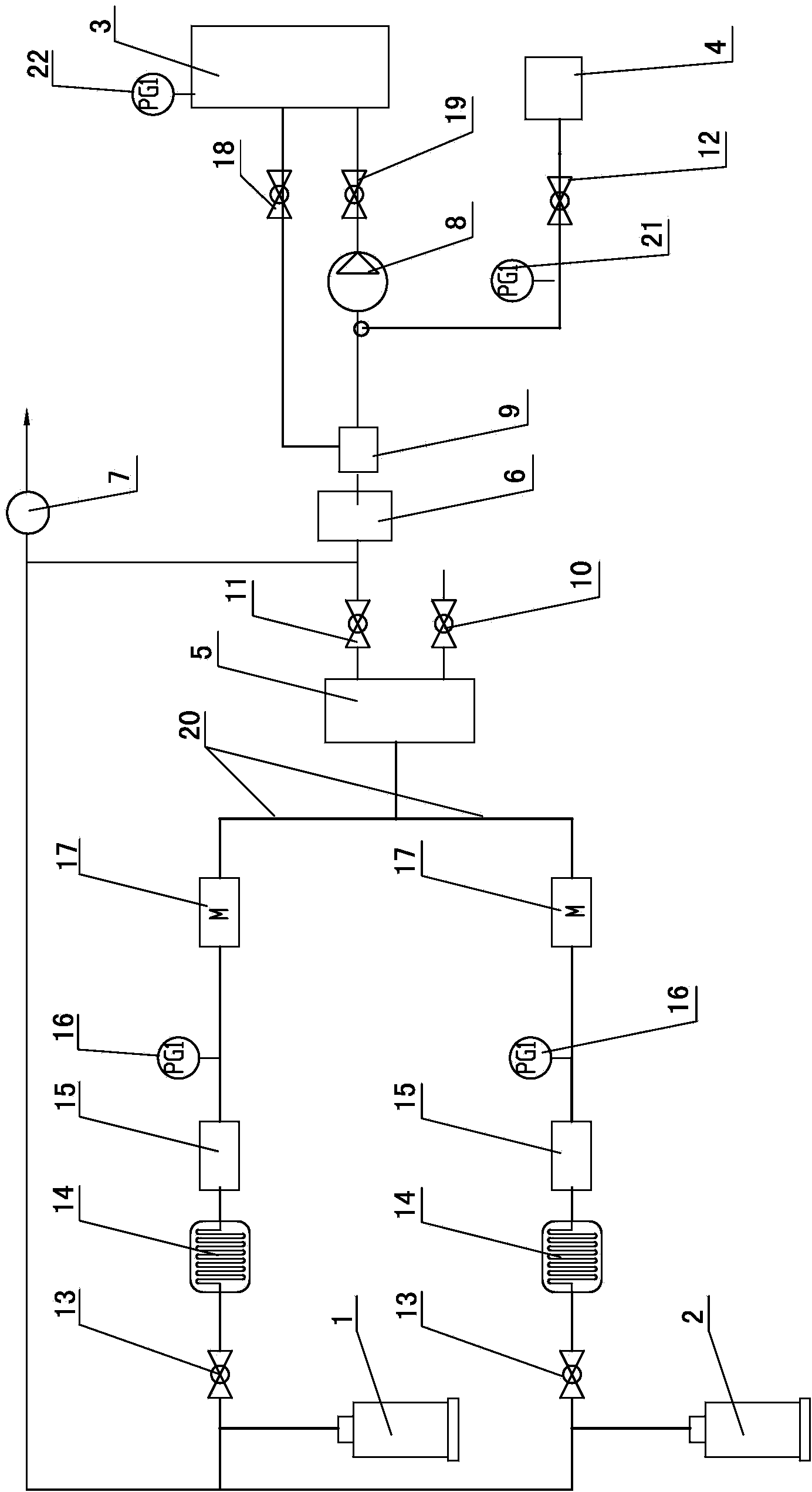

[0011] The present invention will be further described below in conjunction with the accompanying drawings. exist figure 1 In the illustrated embodiment, the gas in the first cylinder is CF 4 , SF 6 Air supply circuit and CF 4 The structure of the supplementary air circuit is the same, and both include a pipeline 18 provided with a manual valve 13, a fan heat exchanger 14, a decompression regulator 15, a first pressure gauge 16 and a mass flow controller 17 in sequence, and the pipeline 18 is close to the fan exchanger. One end of the heater 14 communicates with SF 6 The gas cylinder 1 or the first gas cylinder 2, the other end of the second pipeline 18 communicates with the gas mixer 5. The gas mixer 5 adopts a spiral tube with an isolation baffle, and has two output ends. One output end is connected to the atmosphere through the first control valve 10, and the other output end is passed through the second control valve 11, the buffer tank 6, and the electromagnetic flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com