Method for constructing core tube wall through self-climbing formwork and adopted self-climbing formwork

A core tube and formwork technology, which is applied to the accessories of scaffolding, formwork/formwork/work frame, and processing of building materials, etc., can solve the problem that scaffolding cannot be used, and achieve saving construction materials, high safety, and reducing Bump damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

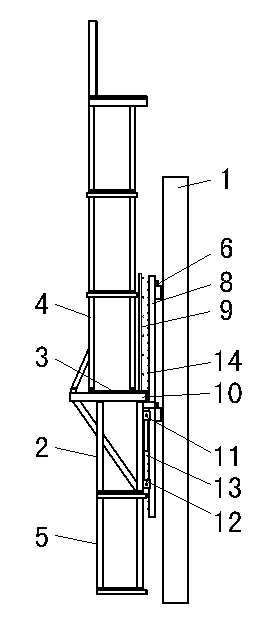

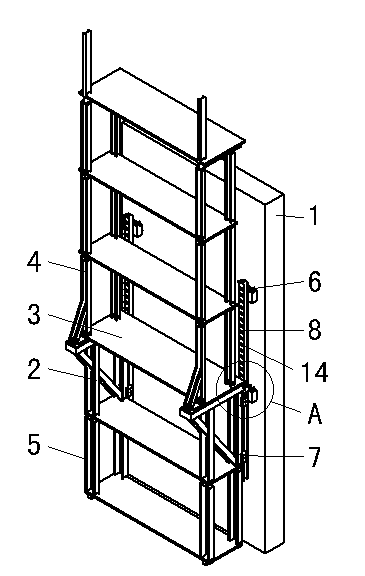

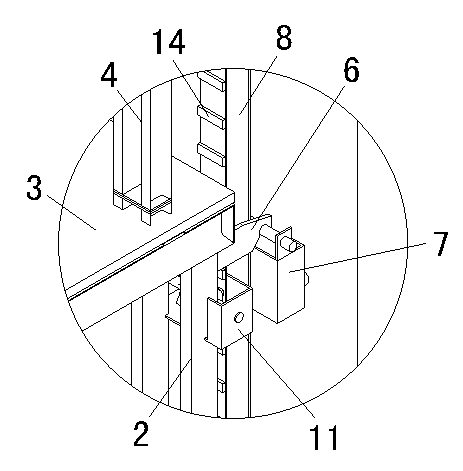

[0033] This example takes the R&F Yingkai Plaza project located in the core business district of Zhujiang New Town, Guangzhou as an example. The land area of this project is 7942m 2 , with a total construction area of 184,204 m 2 , of which 151573 m above ground 2 , 32631 m underground 2 , 65 floors above ground, 5 floors underground, the foundation pit of the podium is 24.45m deep, the foundation pit in the core tube is 30.9m deep, and the total height of the tower is 296.5m. The main structure is a frame-core tube structure, and the core tube is a reinforced concrete structure.

[0034] According to the characteristics of the vertical structure of the core tube in this example and the actual situation, the inner wall of the core tube, including the inner side of the outer wall, adopts the construction method of self-climbing formwork. Comprehensive consideration of various factors such as progress, safety, and economy requires that a plurality of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com