String bag type lower jawbone implant applying three-dimensional printing technology

A three-dimensional printing and mandible technology, applied in the medical field, can solve problems such as poor mandibular repair work effect, and achieve the effect of overcoming the poor effect, improving the effect, and ensuring the success of the repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

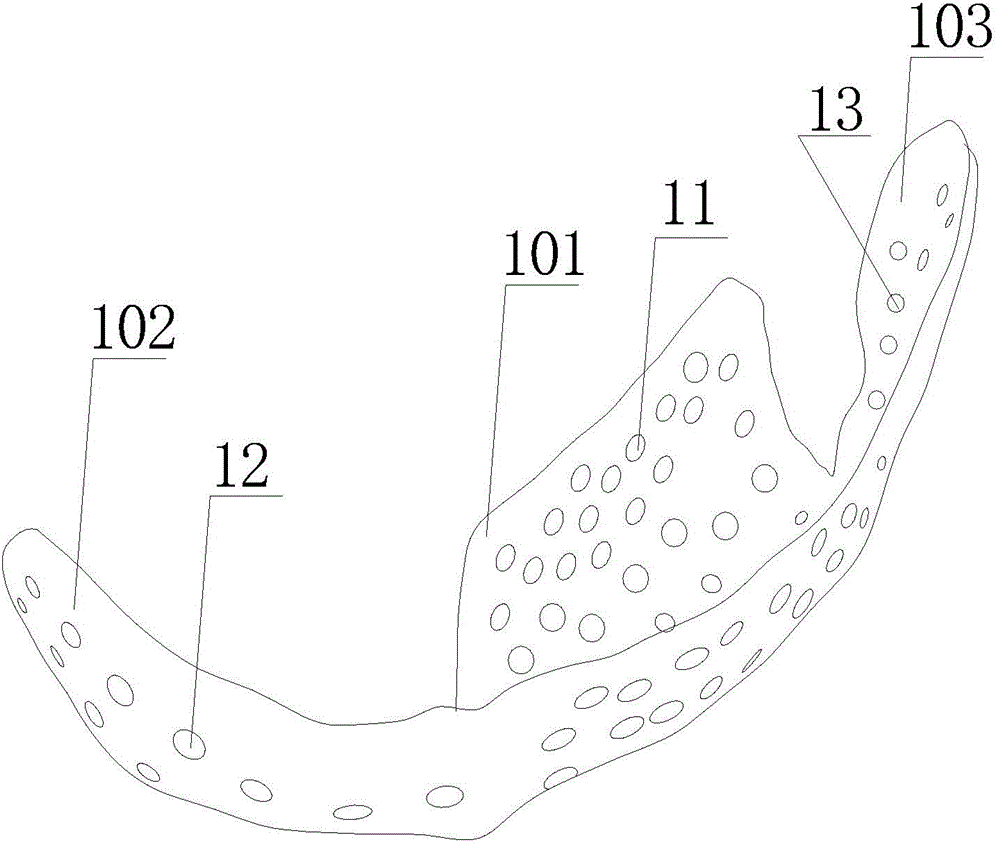

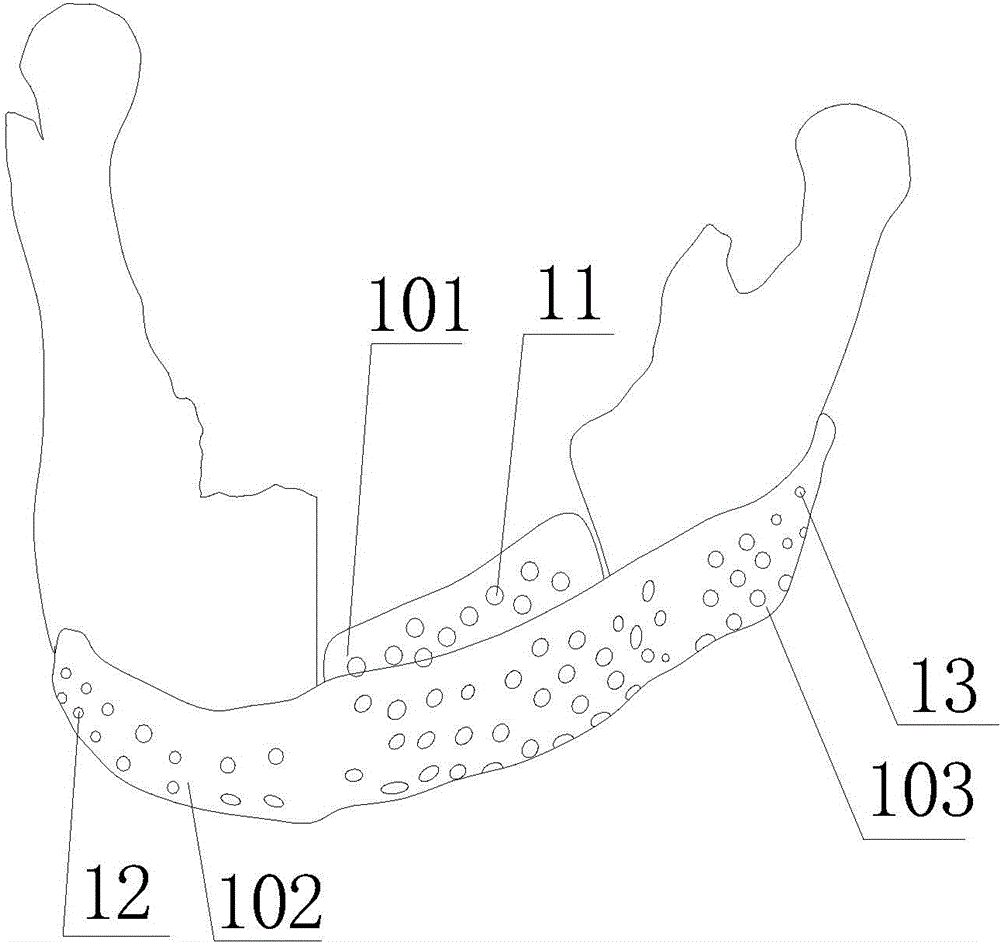

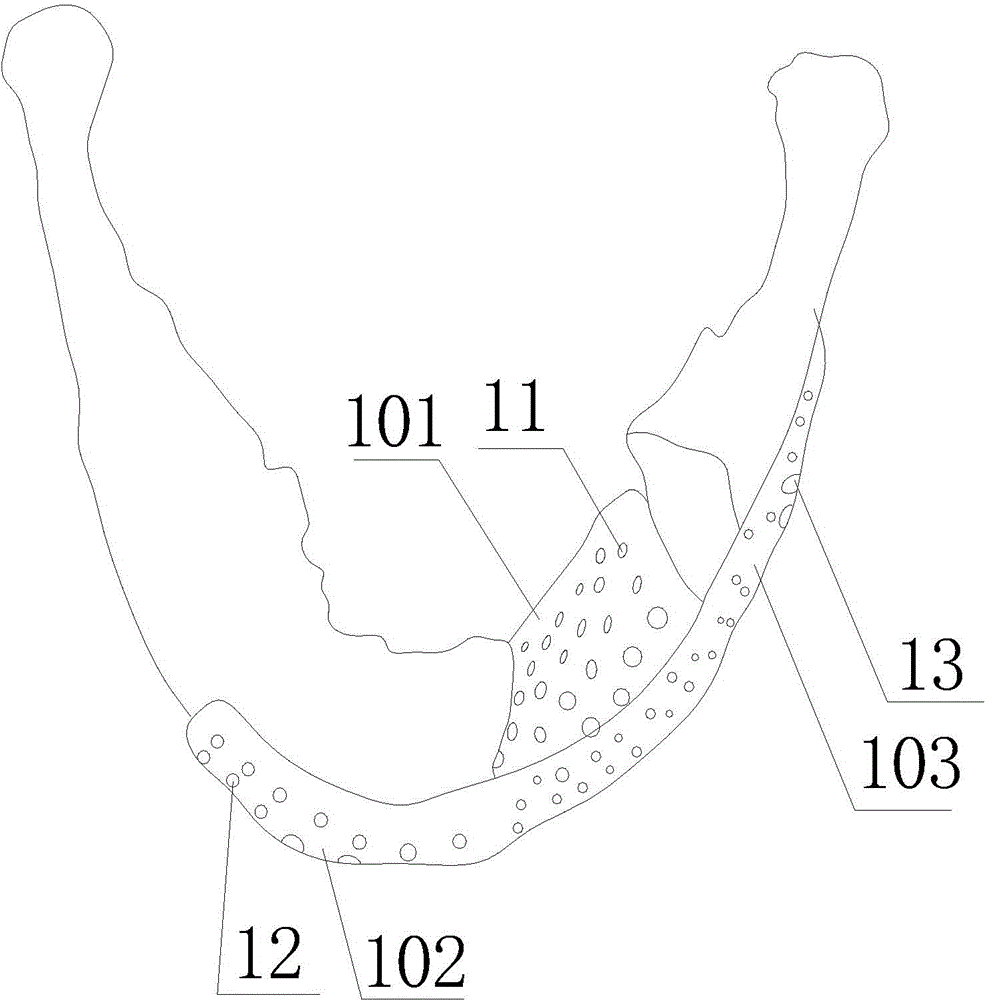

[0024] figure 1 It is a schematic diagram of the structure of the net bag type mandibular implant provided by the embodiment 1 of the present invention using the three-dimensional printing technology; figure 2 It is a schematic diagram of the frontal structure of the net bag type mandibular implant provided by the embodiment 1 of the present invention using the three-dimensional printing technology; image 3 It is a schematic diagram of the top view structure of the mandibular net implant using 3D printing technology provided by Embodiment 1 of the present invention; as shown in the figure, the net mandibular implant using 3D printing technology provided by Embodiment 1 of the present invention includes: The diameter of the gingiva is larger than the lower edge of the mandible with a net bag-type main body 101. The two ends of the net bag-type main body 101 are respectively integrally formed with a mesial healthy side fixer 102 and a distal healthy side fixer 103. The net bag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Round hole diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com