A hvpe reactor with improved substrate gas flow direction

A technology of gas flow direction and reactor, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of uneven substrate S reaction, reduce engineering appendages, simplify manufacturing process, and improve uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

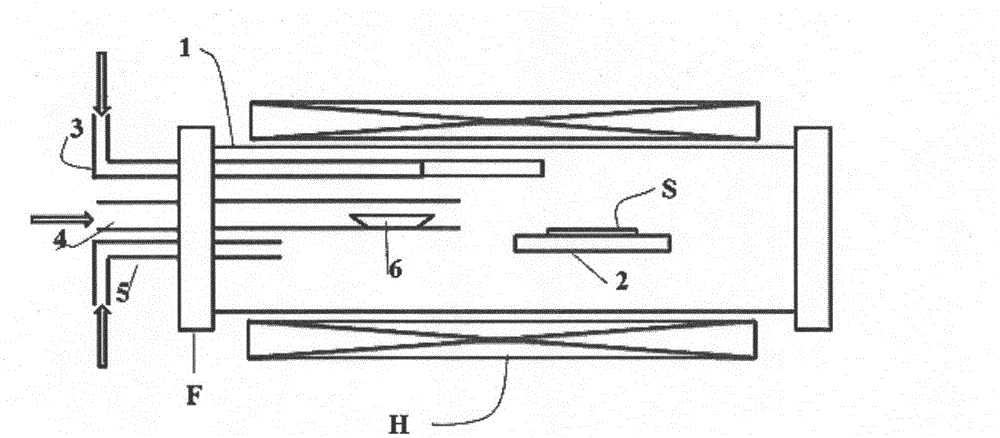

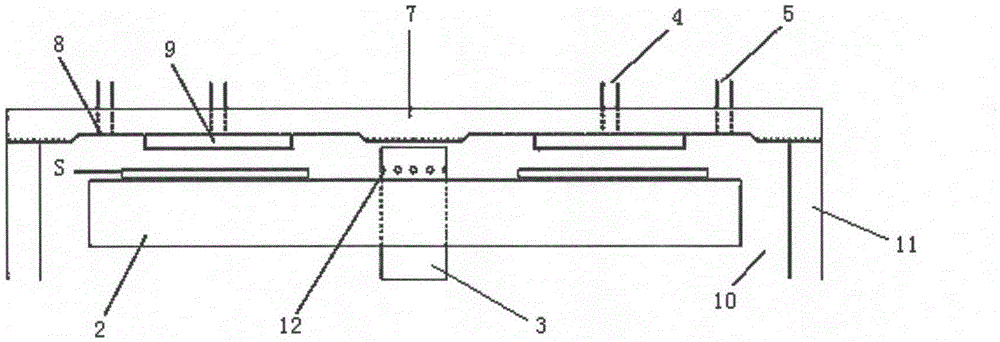

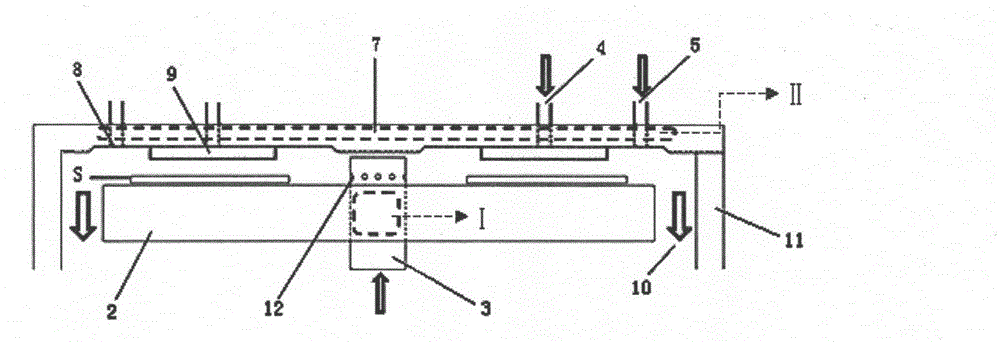

[0022] Such as figure 2 As shown, a schematic structural view of a HVPE reactor for improving the direction of substrate airflow provided by the present invention includes a housing 11, a trunk 7 is installed on the top of the housing 11, and one side of the trunk 7 is inserted into the injection pipe-8, Jet pipe two 9, the other side inserts and installs air intake pipe two 4, air intake pipe three 5. Injection pipe one 8, injection pipe two 9 and intake pipe two 4, air intake pipe three 5 are respectively positioned at the both sides of trunk 7 center, and lined up, and injection pipe two 9 and intake pipe two 4 are closer to trunk 7 center. Injection pipe two 9, air intake pipe two 4 pass the end that trunk 7 is located in housing 11 and install a spray plate larger than its own pipe diameter. Housing 11 is provided with a substrate seat 2, on which two substrates S are placed, respectively located on both sides of the center of the substrate seat 2, one is located below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com