Construction technology of cast-in-place lightweight foam concrete

A foamed concrete and lightweight foam technology, which is applied in the field of construction engineering, can solve problems such as foam concrete bedding and cracks, and achieve the effect of stabilizing bubbles and reducing labor input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

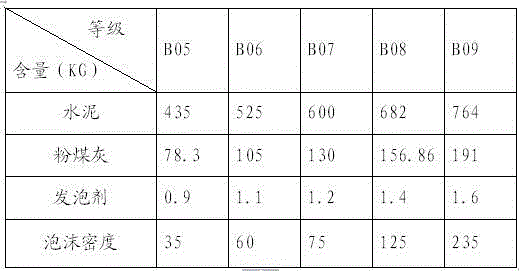

[0054] Preparation of cement slurry solution: Add 435 kg of cement, 78.3 kg of fly ash, and 174 kg of water to the mixing bucket I of the hydraulic foaming machine and stir for 0.7 min. The weight ratio of the above cement, fly ash, and water is 1:0.18:0.4 .

[0055] Preparation of foaming agent aqueous solution: Add 0.9 kg of foaming agent and 58.5 kg of water to the mixing bucket II of the foaming hydraulic machine and stir for 4 minutes. The weight percentage of the above foaming agent and water is 1:65. After stirring, the foam density is 35kg / m 3 .

[0056] Preparation of foamed concrete: Put the foaming agent aqueous solution into the cement slurry solution and stir for 2 minutes, the weight percentage of the foaming agent aqueous solution and the cement slurry solution is: 1:13.8.

Embodiment 2

[0058] Preparation of cement slurry solution: Add 525 kg of cement, 105 kg of fly ash, and 262.5 kg of water to the mixing bucket I of the hydraulic foaming machine and stir for 0.5 min. The weight ratio of the above cement, fly ash and water is 1:0.2:0.5.

[0059] Preparation of foaming agent aqueous solution: add 1.1 kg of foaming agent and 74.8 kg of water into the mixing bucket II of the foaming hydraulic machine and stir for 5 minutes. The weight percentage of the foaming agent and water is 1:68. After stirring, the foam density is 60kg / m 3 .

[0060] Preparation of foamed concrete: put the foaming agent aqueous solution into the cement slurry solution and stir for 1.5 min, the weight percentage of the foaming agent aqueous solution and the cement slurry solution is: 1:12.

Embodiment 3

[0062] Preparation of cement slurry solution: add 600 kg of cement, 130 kg of fly ash, and 390 kg of water to the mixing bucket I of the hydraulic foaming machine and stir for 0.8 min. The weight ratio of the above cement, fly ash and water is 1:0.22:0.65.

[0063] Preparation of foaming agent aqueous solution: Add 1.2 kg of foaming agent and 84 kg of water to the mixing bucket II of the foaming hydraulic machine and stir for 3 minutes. The weight percentage of the above foaming agent and water is 1:70. After stirring, the foam density is 75kg / m 3 .

[0064] Preparation of foamed concrete: Put the above-mentioned foaming agent aqueous solution into the cement slurry solution and stir for 1.5 minutes. The weight percentage of the foaming agent aqueous solution and the cement slurry solution is: 1:13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com