Cover-turning type elastic absorption assembly clamp

An assembly jig and flip-up technology, which is applied to manufacturing tools, workpiece clamping devices, etc., can solve the problems of long working hours, poor quality effect, low yield rate, etc., and achieve the effects of reduced material loss, low cost and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

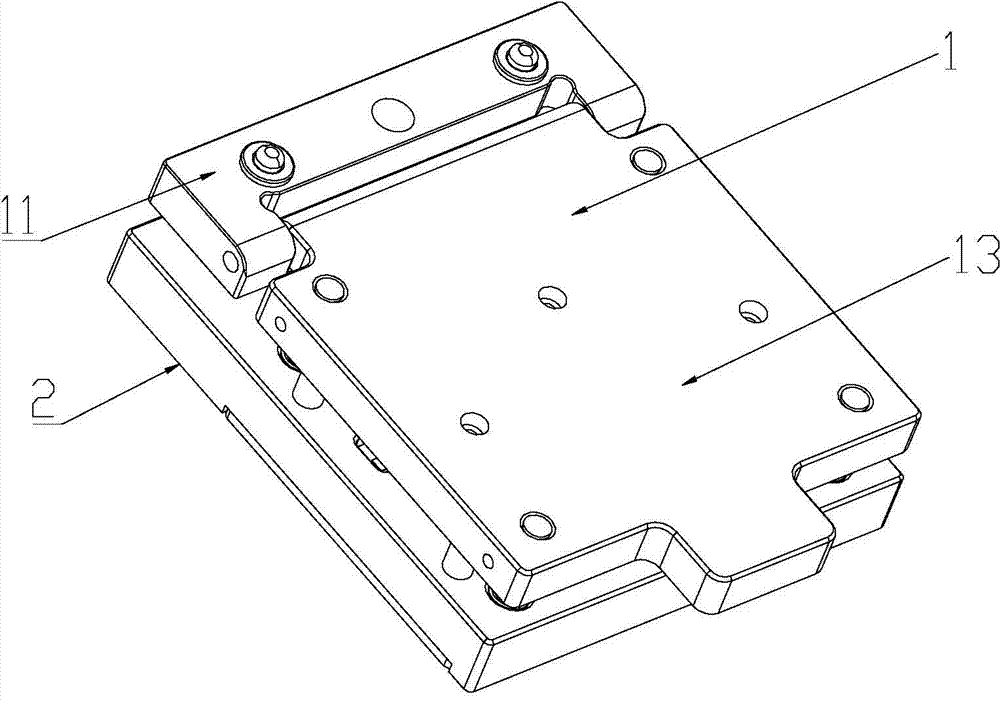

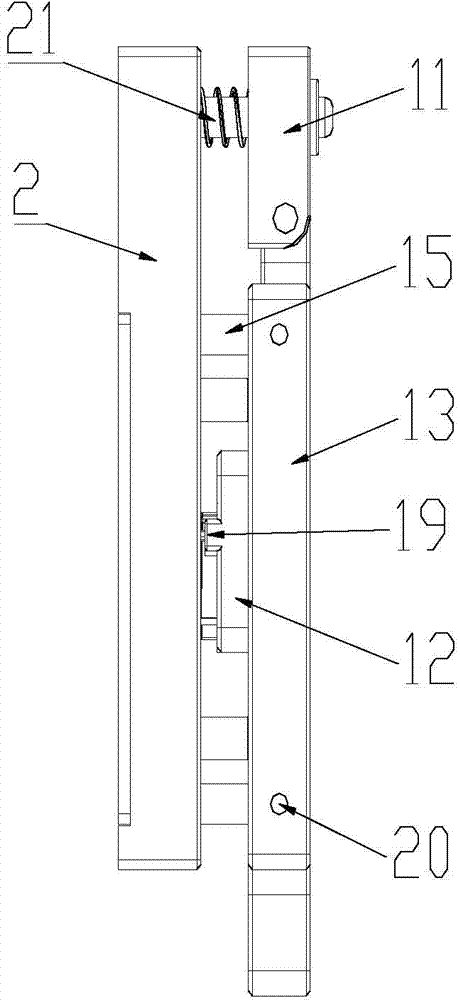

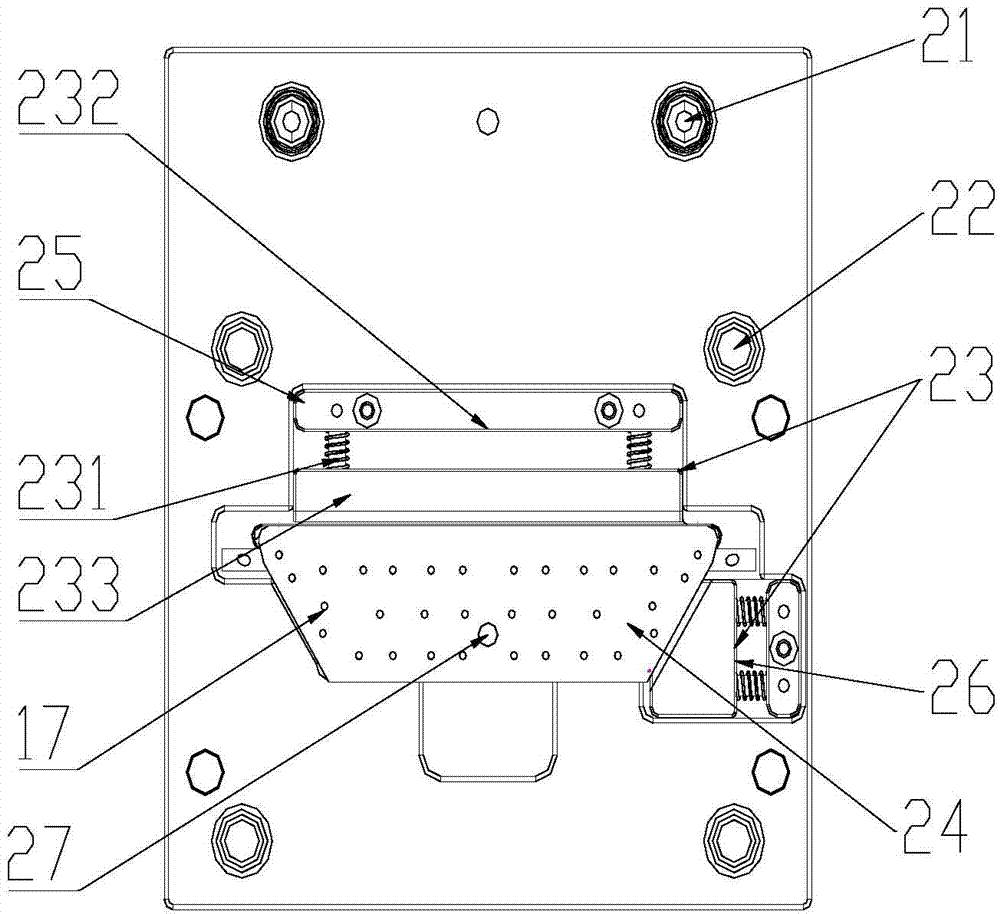

[0030] A flip-type elastic adsorption assembly fixture, comprising an upper mold 1 and a lower mold 2; the upper mold 1 includes a connecting block 11 at the top, an upper mold core 12 and a flip-type upper template 13; the flip-type upper template 13 can be It is rotatably connected to the connecting block 11; two hole-shaped guide sleeves 14 are provided on the connecting block 11; four corners of the flip-type upper template 13 are provided with upper guide posts 15, the upper guide posts 15 protrudes toward the surface close to the lower mold 2; the upper mold core 12 is located in the center of the flip-type upper mold plate 13, and the surface of the upper mold core 12 close to the lower mold 2 is provided with a vacuum suction positioning structure 16 and a center positioning column 19 , The vacuum suction positioning structure 16 includes a number of exhaust holes 17 located inside and positioning rods 18 located on the edge; the lower mold 2 includes a lower guide colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com