A foldable bed guard

A guardrail and bed body technology, applied in the field of bed guardrails, can solve problems such as unsmoothness, troublesome disassembly and assembly of bed guardrails, storage space occupied by bed guardrails, etc., to achieve the effect of convenient disassembly and assembly, and avoid inconvenient disassembly and assembly defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

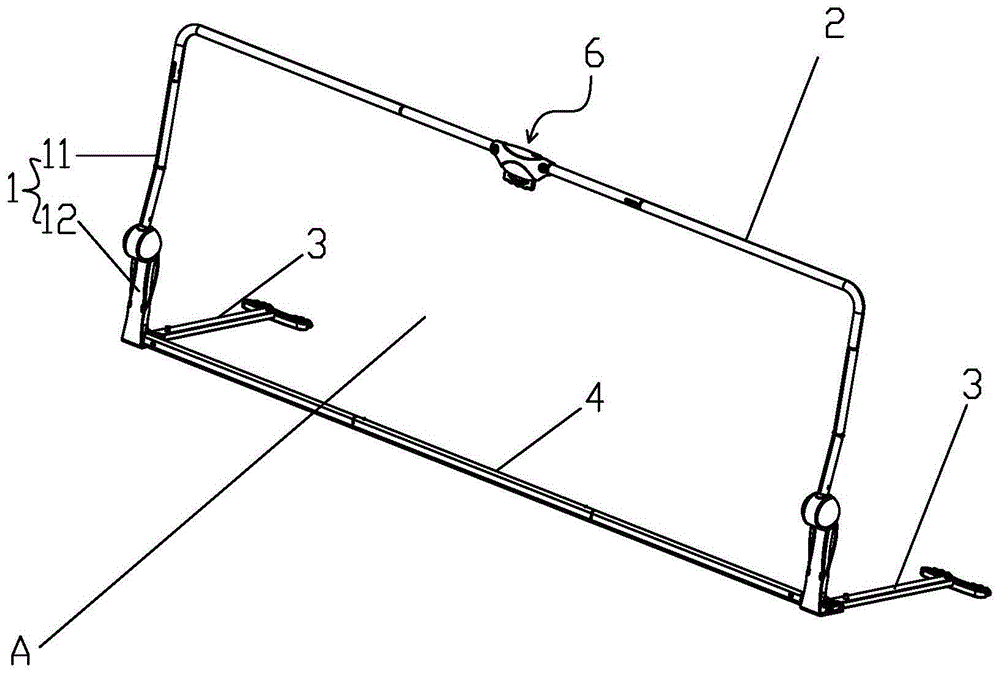

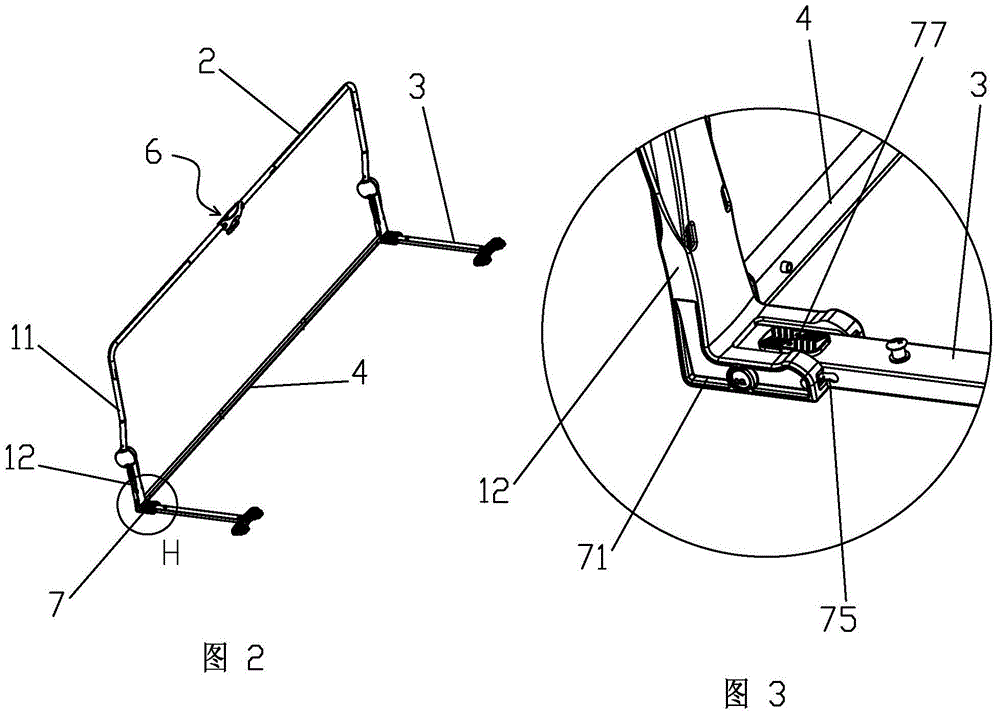

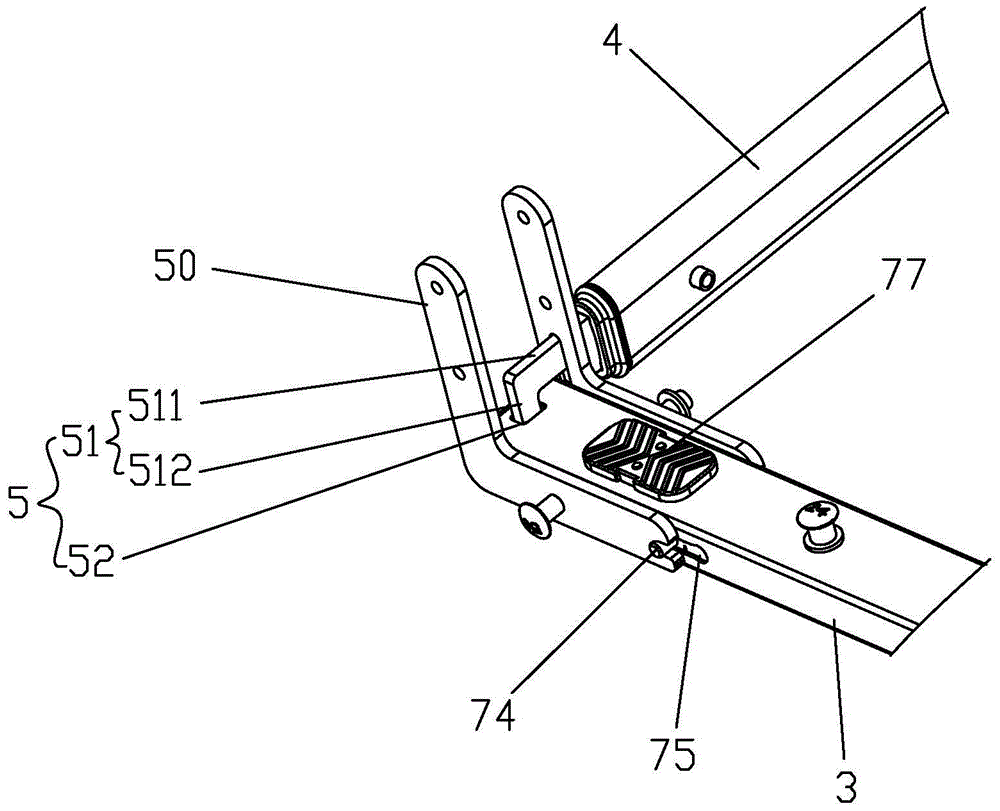

[0047] Such as figure 1 , figure 2 As shown, a foldable bed guardrail includes foldable vertical rods 1 arranged on the left and right sides, and the upper and lower ends of the vertical rods 1 on the left and right sides are respectively connected with an upper horizontal rod 2 and a lower horizontal rod 4, The two vertical bars 1 are connected with the upper rail 2 and the lower rail 4 to form a guardrail frame A, and the bottom of the frame A is provided with a supporting leg 3 connected with the bed body to prevent the frame A from falling over. Both ends of the bar 4 extend into the vertical bar 1, and a locking device 5 is provided between the support leg 3 and the end of the lower cross bar 4 to lock the two to lock the frame A. The support leg 3 and the A driving device 7 is provided between the vertical bars 1 to fold the supporting legs 3 and drive the locking device 5 to unlock, and the frame A is provided with a folding device 6 to fold the bed guardrail. The dr...

Embodiment 2

[0057] Such as Figure 11 , 12 As shown, the difference between embodiment 2 and embodiment 1 is:

[0058] A telescopic rod 13 is connected to the upper vertical rod 11, and the telescopic rod 13 includes a thick rod segment 131 and a thin rod segment 132, and a step 133 is provided at the connection between the thick rod segment 131 and the thin rod segment 132, Both ends of the upper cross bar 2 are provided with bent pipe sections 22, and the described bent pipe sections 22 are sleeved on the thin rod section 132. Afterwards, the thin rod section 132 is retracted into the locking pin 81 in the elbow section 22 . When the user presses the lock pin 81 with a finger, the bent pipe section 22 moves downward to enclose the thin bar section 132, and is finally blocked by the step 133 to complete the descent of the upper cross bar 2 and reduce the height of the bed guardrail.

Embodiment 3

[0060] Such as Figure 13 As shown, the difference between embodiment 3 and embodiment 2 is:

[0061] The lower part of the two upper vertical bars 11 is provided with a reinforcing cross bar 8 connecting the two. The setting of reinforcing cross bar 8 can increase the structural strength of bed guardrail, makes it not easily deformed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com