Hook body of industrial hook

An industrial, hook-body technology, applied in furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of large draw hook loss, inability to hook objects, trouble, etc., to extend the use time, reduce wear and tear, and easily hook. The effect of taking an object

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

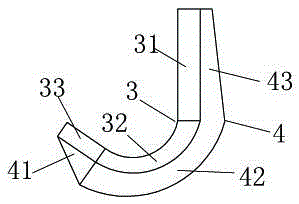

[0009] Combine below figure 1 with figure 2 Specific description embodiment:

[0010] Such as figure 1 with figure 2 As shown, the industrial pull hook, the industrial pull hook includes a pull rod 1 and a hook body 2, the hook body 2 includes an upper hook body 3 and a lower hook body 4, one end of the upper hook body 3 and the lower hook body 4 They are respectively fixedly connected to one end face of the pull rod 1, and the connection contact area of the upper hook body 3 and the pull rod 1 is twice the connection contact area of the lower hook body 4 and the pull rod 1; the upper hook body 3 is formed by a straight rod 31 , a curved bar 32 and an inclined bar 33, the straight bar 31 is located in the axial direction of the tie rod 1, the angle between the straight bar 31 and the inclined bar 33 is 45 degrees, the straight bar 31 Length is three times of the length of oblique bar 33; Described lower hook body 4 is made of front hook 41, middle bar 42 and tail bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com