Indoor automatic sticking device

A clamping device and plate rolling technology, applied in decorative arts, pasting, etc., can solve the problems of easy danger, time-consuming and laborious posting, etc., and achieve the effect of small footprint and small height error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

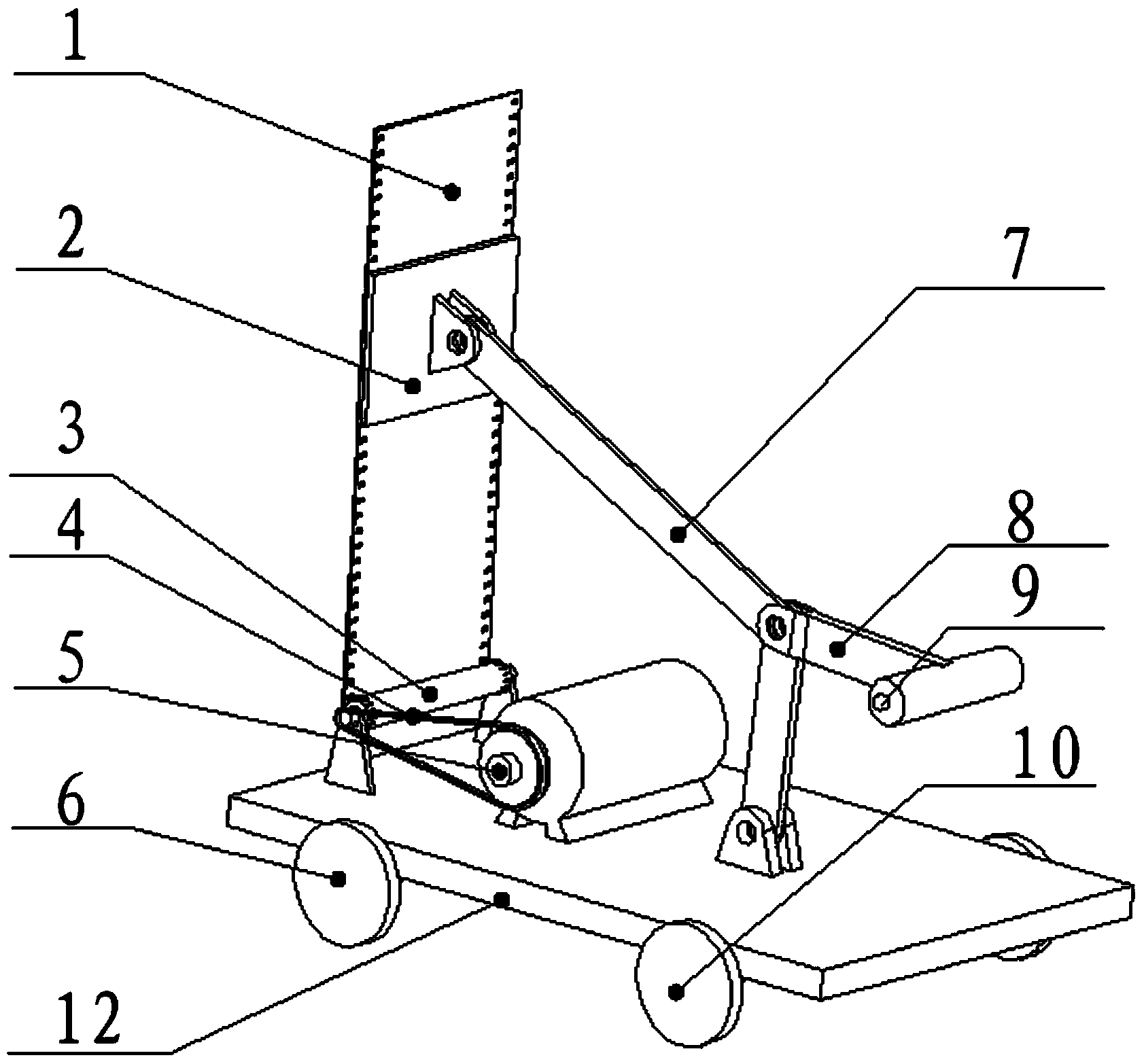

[0009] An indoor automatic pasting device is composed of 1. rolling plate, 2. clamping device, 3. gear rod, 4. belt, 5. motor, 6. front wheel, 7. two connecting rods, 8. push rod, 9 , motor switch, 10, rear wheel, 11 battery, 12, chassis, coil plate 1 is connected with clamping device 2, coil plate 1 is connected with gear rod 3, motor 5 and gear rod 3 are connected through belt 4, and two consecutive The rod 7 is connected to the push rod 8, the second connecting rod 7 is connected to the clamping device 2, the motor switch 9 is placed in the push rod 8, the coil plate 1, the gear rod 3, the motor 5, and the second connecting rod 7 are placed on the chassis 12, The front wheel 6 and the rear wheel 10 are respectively placed in the front and back of the chassis, and the storage battery 11 is connected to the chassis 12 .

[0010] When the device is working, the motor 5 drives the coil 1 to move upward, and when it reaches the set height, the clamping device 2 is moved forward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com