A steamed bun machine

A steamed bun machine and steamed bun technology, which is applied to cooking utensils, household utensils, applications, etc., can solve the problems of unsatisfactory steamed buns, and achieve the effect of excellent taste and white, tender and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

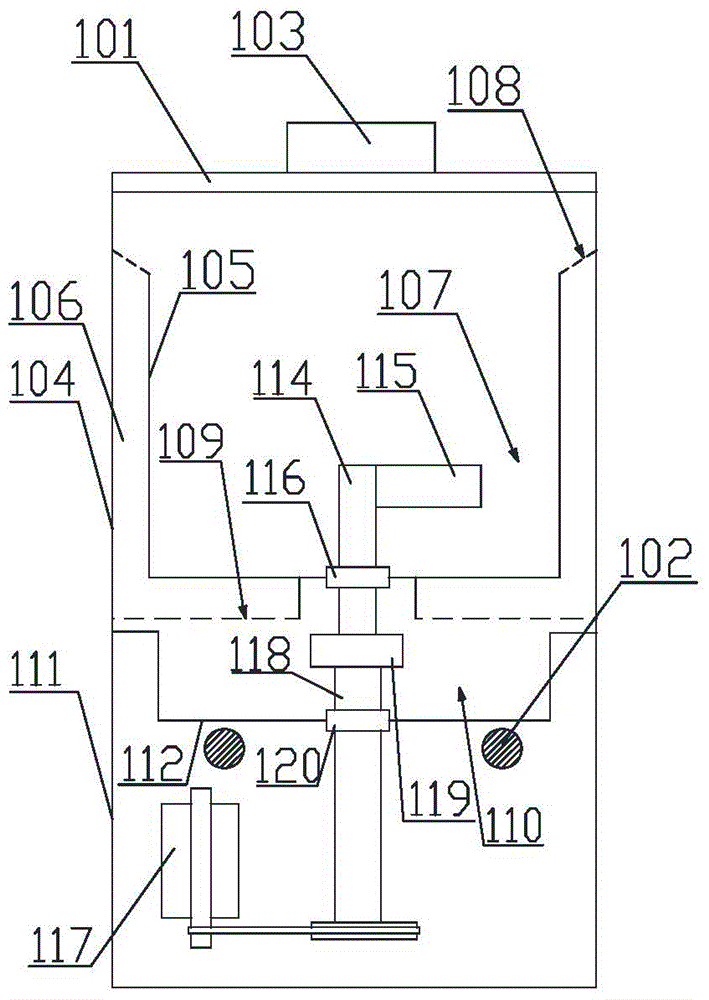

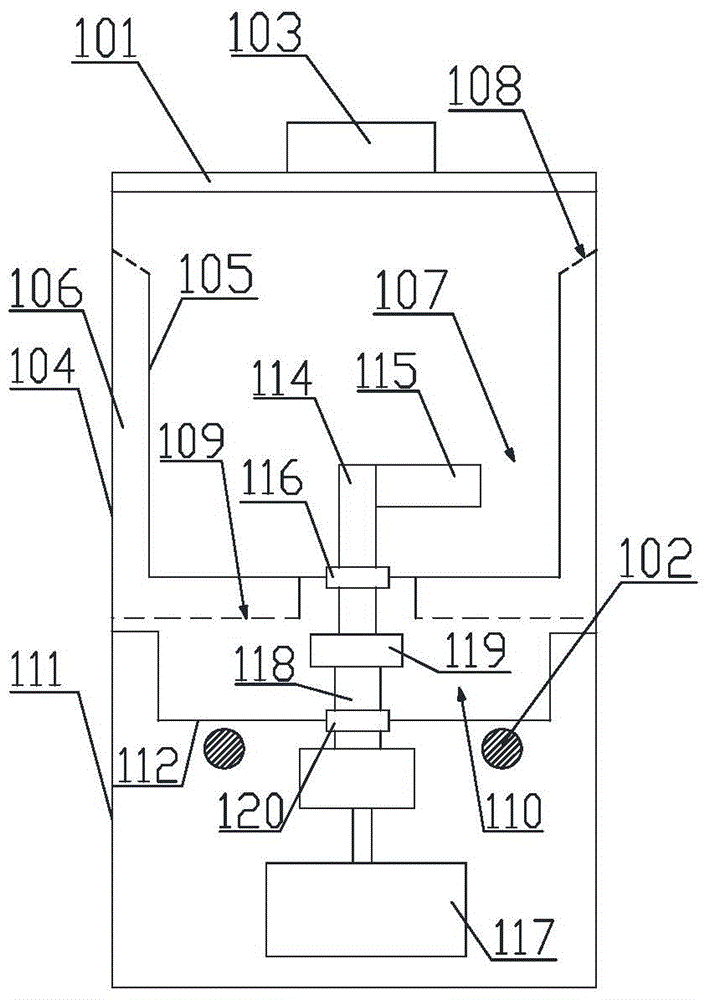

[0023] combine figure 1 As shown, a steamed bun machine includes a steamed bun bucket, a bucket cover 101, a heating device 102, a stirring device and a stirring driving device. The bucket cover 101 is arranged on the steamed bun bucket. The lid 101 is provided with a steam hole 103, which ensures that the lid 101 will not be jacked up due to excessive steam in the steamed bun barrel while ensuring sufficient steam in the steamed bun barrel.

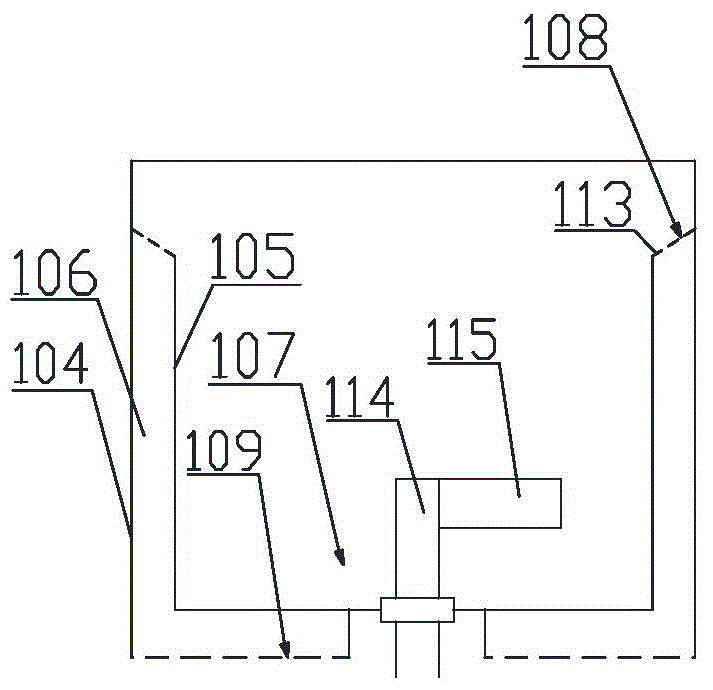

[0024] Such as image 3 , Figure 4 and Figure 5 As shown, the steamed bun barrel has double-layer barrel walls, that is, an outer barrel wall 104 and an inner barrel wall 105 . The outer barrel wall and the inner barrel wall are connected by nesting, and an interlayer 106 is provided between the outer barrel wall 104 and the inner barrel wall 105 . The raw material placement area 107 is located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com