A data processing device and method for conventional performance parameters of a steam turbine

A data processing device and data processing technology, which are used in measuring devices, testing of machine/structural components, instruments, etc., can solve problems such as low work efficiency, low data acquisition accuracy, and low output result accuracy, and achieve high accuracy. , The effect of high data acquisition accuracy and simple data processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

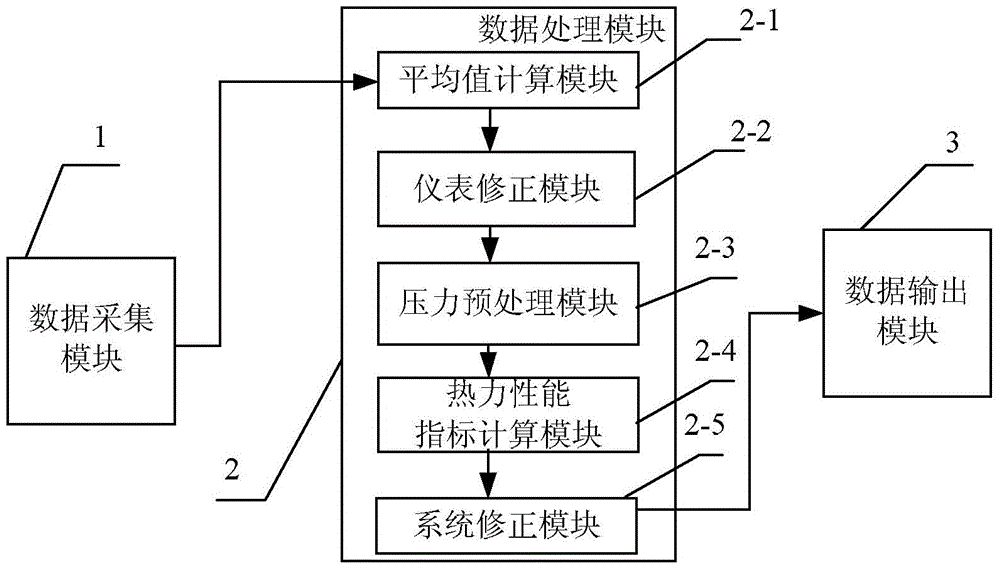

[0023] Specific implementation mode 1, refer to figure 1 Specifically illustrate this embodiment, the data processing device of a kind of steam turbine routine performance parameter described in this embodiment, it comprises: be used for collecting the data acquisition module 1 of steam turbine pressure signal and temperature signal; Be used for calculating and analyzing the data of steam turbine parameter Processing module 2; Data output module 3 for outputting processed data;

[0024] The data processing module includes: average value calculation module 2-1, instrument correction module 2-2, pressure preprocessing module 2-3, thermal performance index calculation module 2-4 and system correction module 2-5;

[0025] The average value calculation module 2-1 is used to receive the pressure or temperature data of the steam turbine collected multiple times by the data acquisition module 1 of the steam turbine parameters, and calculate the average pressure value and the average t...

specific Embodiment approach 2

[0030] Embodiment 2. This embodiment is a further description of the data processing device for conventional performance parameters of a steam turbine described in Embodiment 1. In this embodiment, the data acquisition module 1 is a pressure transmitter or a thermocouple.

[0031] In this embodiment, the pressure transmitter is used to collect the pressure values of water and steam in the thermal system of the steam turbine; the thermocouple is used to collect the temperature values of water and steam in the thermal system of the steam turbine.

specific Embodiment approach 3

[0032] Embodiment 3. According to Embodiment 1 or 2, a data processing method of a data processing device for conventional performance parameters of a steam turbine, the method includes the following steps: a data acquisition step for collecting steam turbine pressure signals and temperature signals; A data processing step for calculating and analyzing steam turbine parameters; a data output step for outputting processed data;

[0033] The data processing steps include:

[0034] The step of receiving the pressure or temperature data of the steam turbine collected multiple times by the data acquisition module 1 for receiving the steam turbine parameters, and calculating the average pressure value and the average temperature value;

[0035] Steps for correcting pressure averages and temperature averages;

[0036] Steps for preprocessing corrected pressure values;

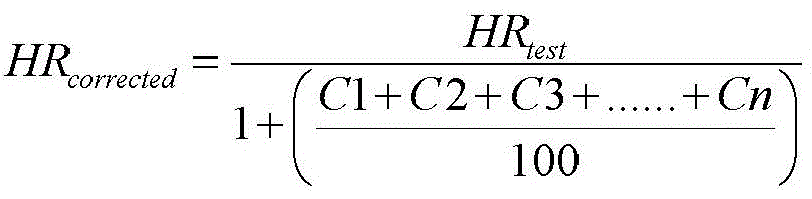

[0037] A step for calculating the thermal performance index of the steam turbine according to the pretreatment co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com