Traction structure for construction of vertical rotating body of arch rib and traction construction method

A construction method and vertical technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of cable tower breakage, waste of production costs, manpower and working hours for erection and dismantling, and save manpower and Material strength, the effect of improving balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

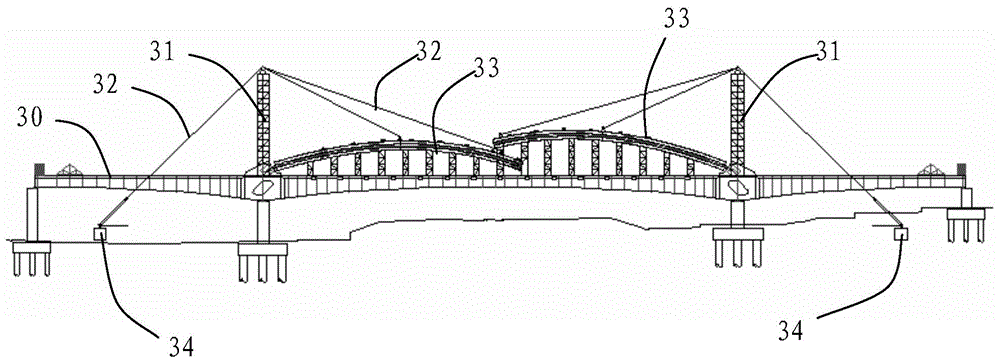

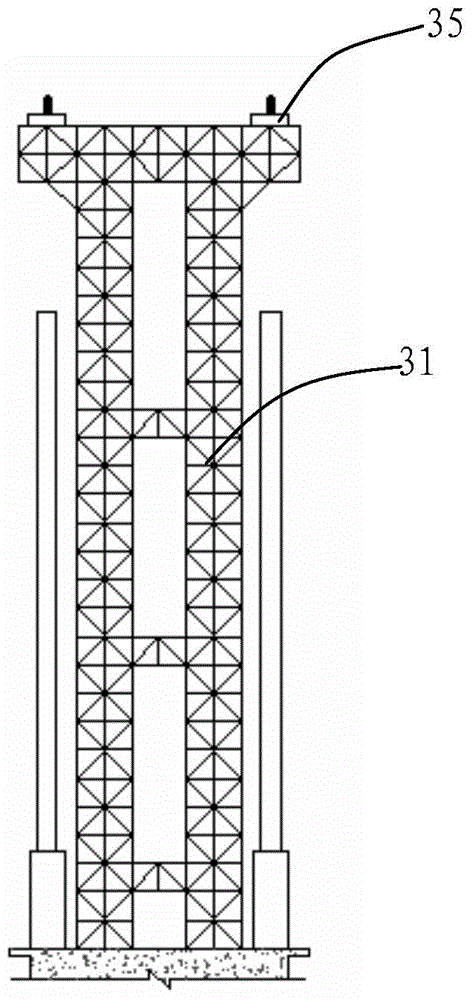

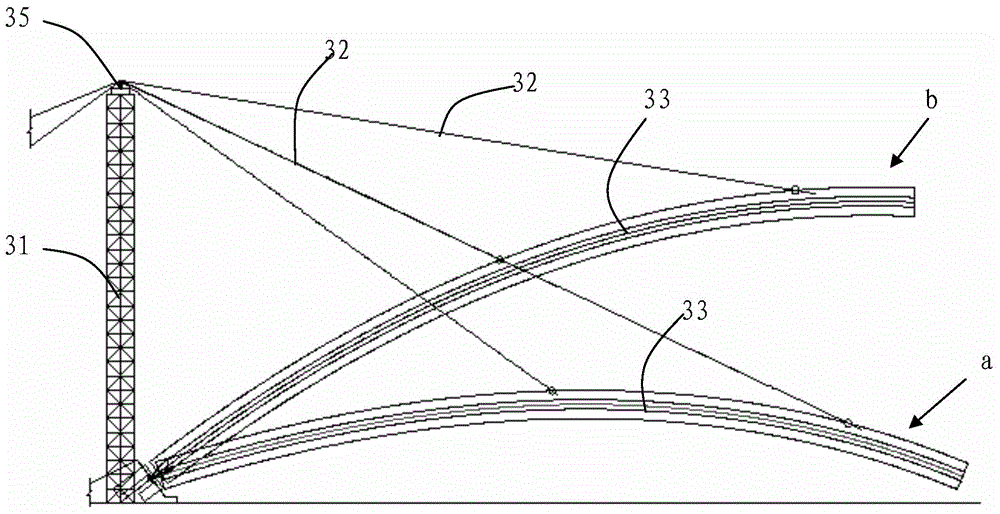

[0036] see first Figure 5 As shown, a traction structure for the vertical swivel construction of an arch rib according to the present invention is mainly composed of a column 11 , a lifting device 12 , a traction rope 13 and a cable wind rope 14 . Cooperate Image 6As shown, the bottom of the column 11 is set on the structural foundation, the lifting device 12 is a jack, fixed on the top of the column 11, the arch rib 21 is arranged on the first side 111 of the column 11, and the end of the arch rib 21 close to the column 11 passes through A hinged seat 22 is hinged on the structural foundation to form a hinged end 151. The arch rib 21 is provided with a traction suspension point 152. The traction rope 13 is pulled between the traction suspension point 152 and the lifting device 12, and is provided by the lifting device 12. The arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com