A kind of glass glaze for easy-folding ampoule and preparation method thereof

A technology for glass glaze and ampoules, which is applied to the field of glass glazes for easy-to-break ampoules and their preparation, and achieves the effects of easy realization, strong breaking force and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

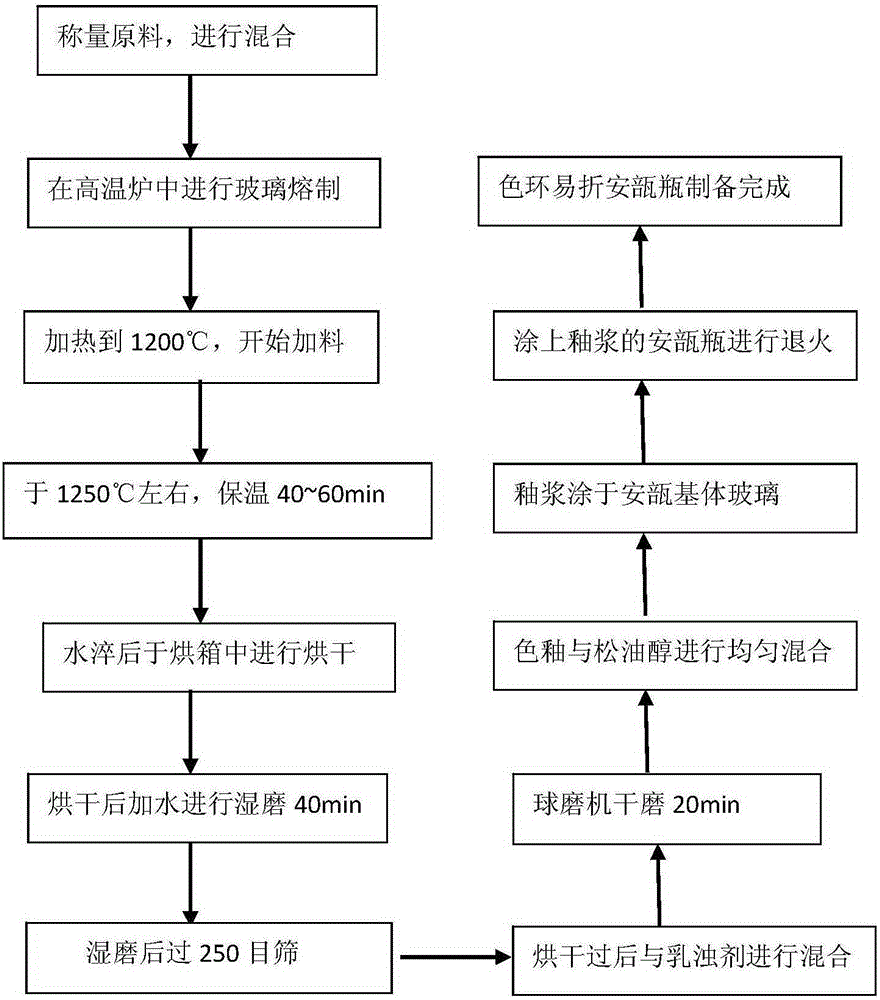

[0022] A kind of preparation method for the glass glaze of frangible ampoule, comprises the following steps:

[0023] 1) According to the mass parts of glass glaze components, 5-20 parts of SiO 2 , 35-60 copies of B 2 o 3 , 0-7 parts of Al 2 o 3 , 5-30 parts of ZnO, 10-30 parts of BaO, 7-30 parts of Na 2 O, 0-10 parts of TiO 2 , 0-5 parts of SnO 2 Mix well to obtain a mixture; the SiO 2 from quartz sand, B 2 o 3 From borax or boric acid, Al 2 o 3 from aluminum hydroxide, ZnO from zinc oxide, BaO from barium carbonate, Na 2 O from borax or sodium carbonate, TiO 2 from Titanium Dioxide, SnO 2 From tin dioxide; the specific operation is: by calculation, according to the mass fraction of each component in the base glaze, quartz sand, sodium carbonate (or borax), boric acid (or borax), zinc oxide, barium carbonate, aluminum hydroxide , titanium dioxide, tin dioxide and other raw materials are evenly mixed to obtain batch materials.

[0024] 2) Melting the mixture in ...

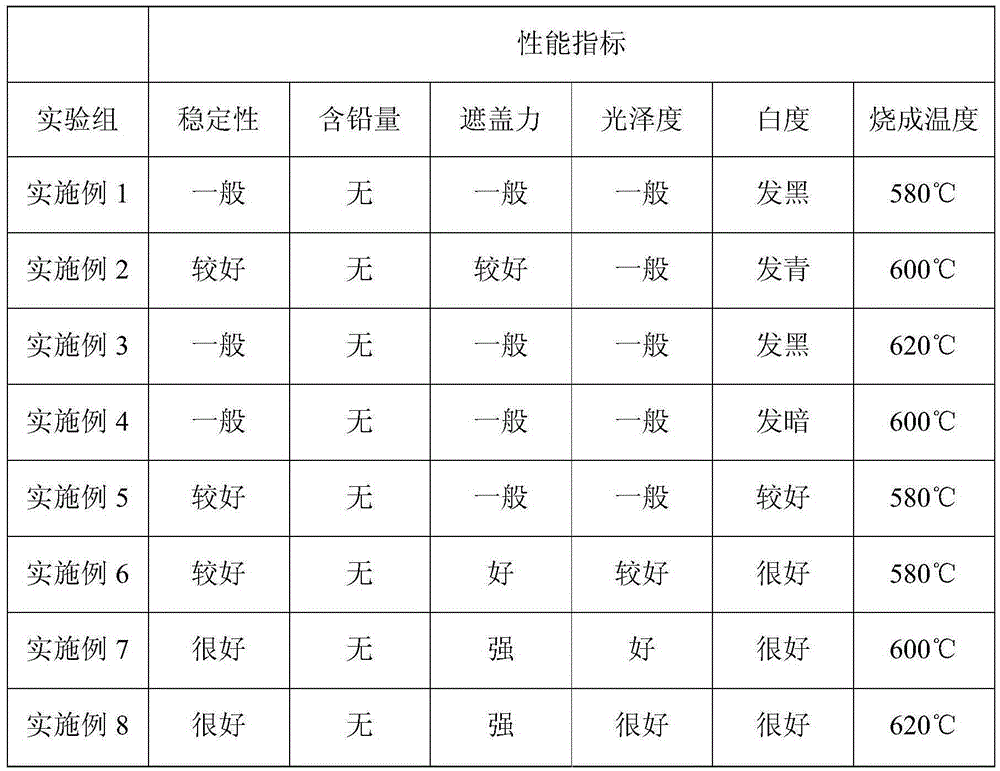

Embodiment 1

[0034] A kind of glass glaze for easy-breaking ampoules, including base glaze and opacifying agent, the components of base glaze are counted in parts by mass, including 2 parts of Al 2 o 3 , 5 parts of SiO 2 , 50 copies of B 2 o 3 , 15 parts of ZnO, 14 parts of BaO, 14 parts of Na 2 O, 2 parts of TiO 2, 2 parts of SnO 2 ; The quality of the opacifying agent is 2.5% of the quality of the basic glaze.

[0035] The above-mentioned preparation method for the glass glaze of easy-folding ampoule, comprises the following steps:

[0036] 1) Weighing aluminum hydroxide, quartz sand, borax, zinc oxide, barium carbonate, sodium carbonate, titanium dioxide and tin dioxide and mixing them uniformly in a mixing device to obtain a mixture;

[0037] 2) adding the mixture into a crucible and melting it in a furnace at 1250° C. to completely melt the mixture to obtain a molten glass, and quenching the molten glass to obtain a glass frit;

[0038] 3) Wet-grind the glass for 40 minutes to...

Embodiment 2

[0042] A kind of glass glaze for easy breaking ampoule, including base glaze and opacifying agent, the components of base glaze are counted in parts by mass, including 2 parts of Al 2 o 3 , 5 parts of SiO 2 , 50 copies of B 2 o 3 , 15 parts of ZnO, 14 parts of BaO, 14 parts of Na 2 O, 3 parts of SnO 2 and 4 parts TiO 2 ; The quality of the opacifying agent is 3.5% of the quality of the base glaze

[0043] The above-mentioned preparation method for the glass glaze of easy-folding ampoule, comprises the following steps:

[0044] 1) Weighing aluminum hydroxide, quartz sand, boric acid, zinc oxide, barium carbonate, sodium carbonate, titanium dioxide and tin dioxide and mixing them uniformly in a mixing device to obtain a mixture;

[0045] 2) adding the mixture into a crucible and melting it in a furnace at 1250° C. to completely melt the mixture to obtain a molten glass, and quenching the molten glass to obtain a glass frit;

[0046] 3) Wet-grind the glass frit for 40 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com