Multi-axis robot

A multi-axis robot and transmission shaft technology, applied in the field of robots, can solve the problems of inconvenient relocation, inconvenient storage, and large space required.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

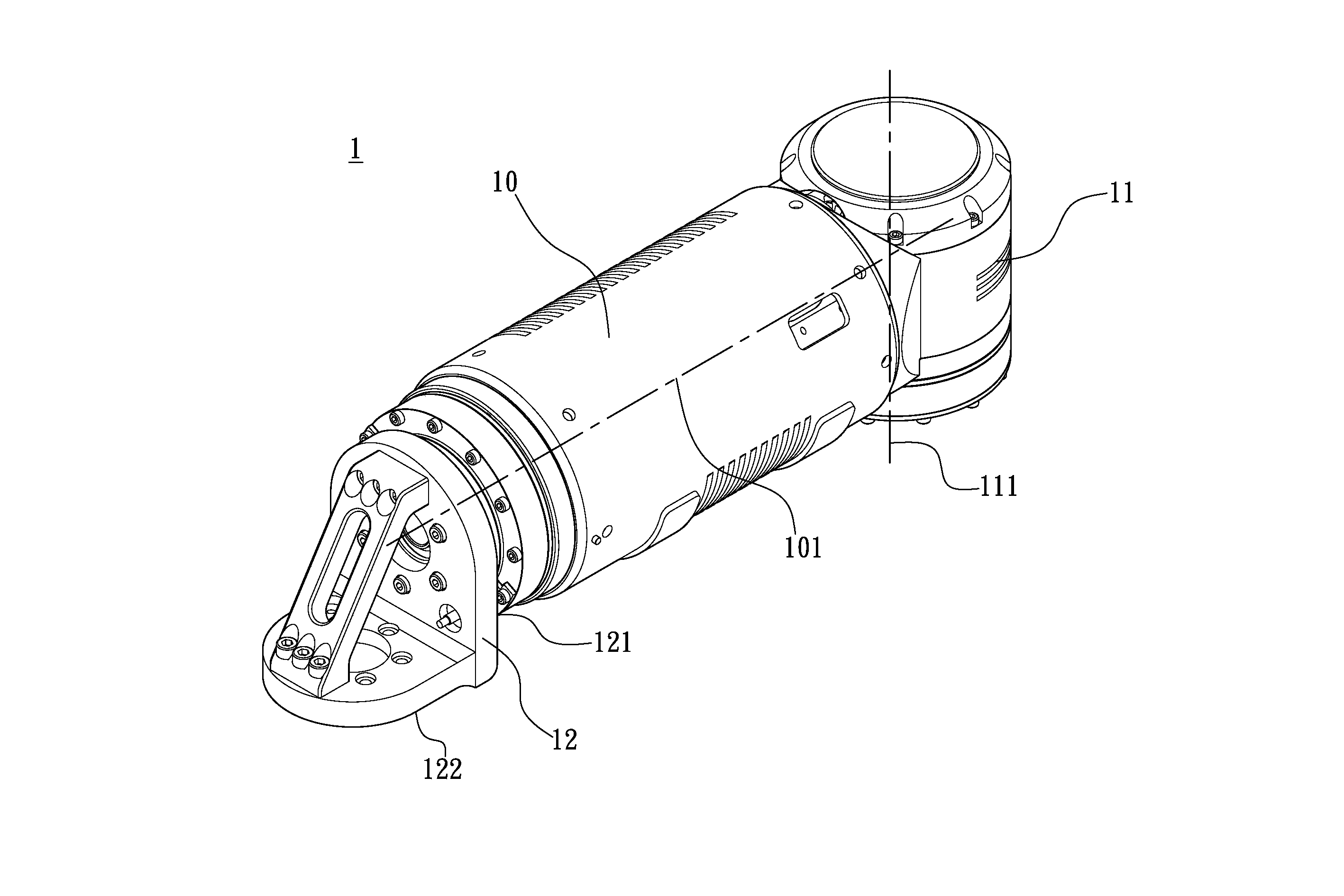

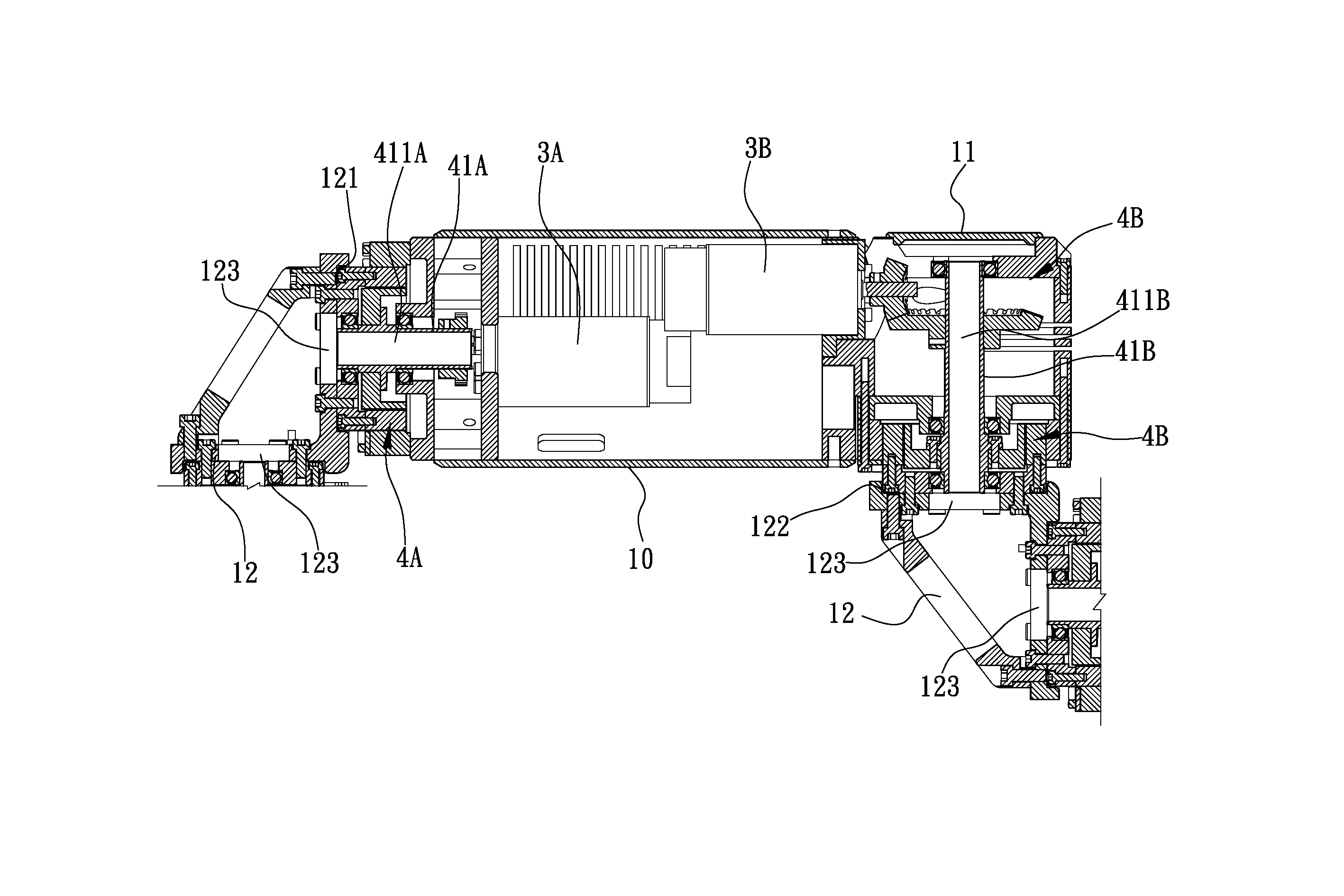

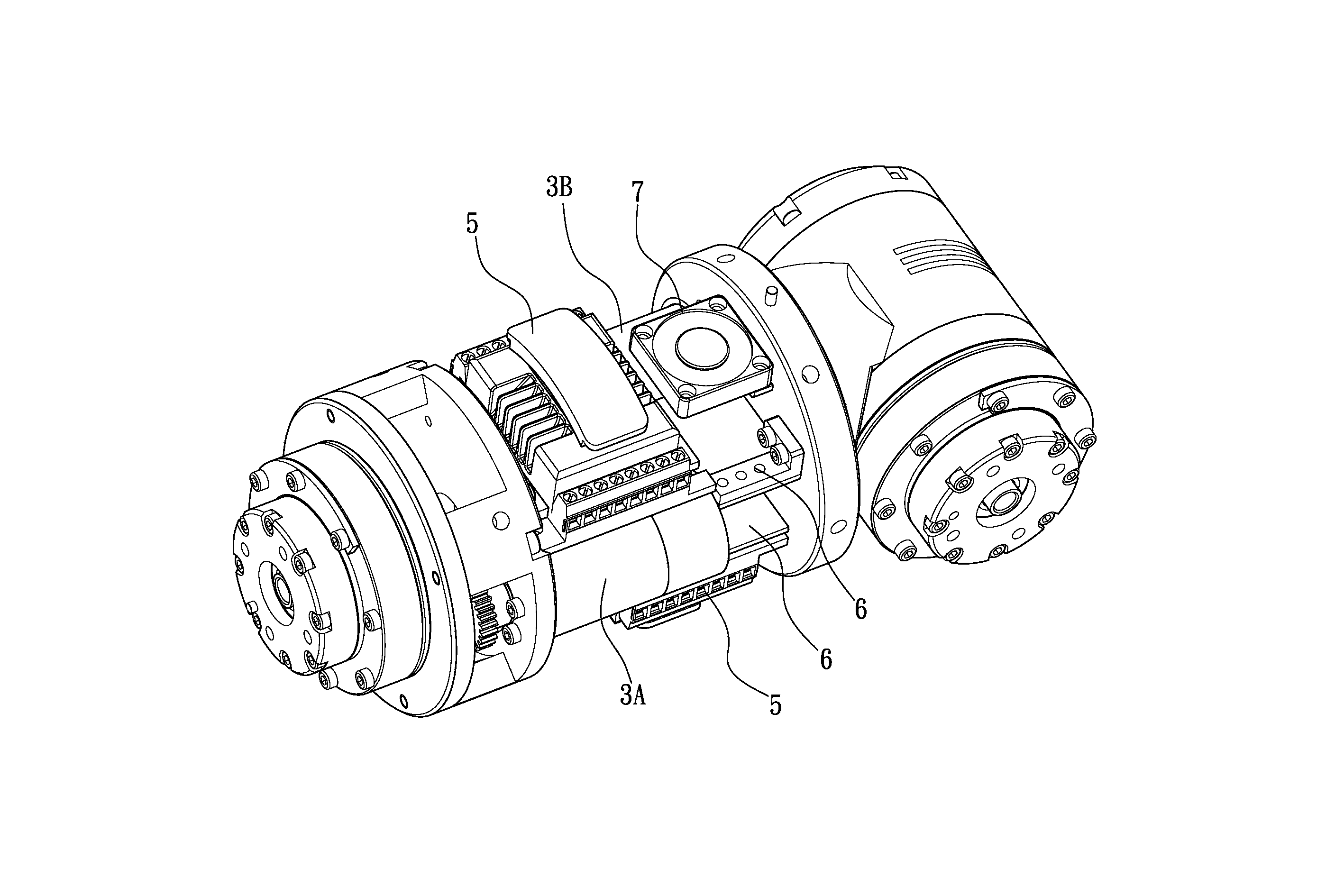

[0034] see Figure 1 to Figure 4 As shown, it is a preferred embodiment of the present invention, the multi-axis robot of the present invention is formed by a plurality of arm assemblies 1, as figure 1 As shown, the arm assembly 1 includes: a first arm portion 10, a second arm portion 11 and a connecting piece 12, one end of the first arm portion 10 and the second arm portion 11 are connected and fixed so that the first arm portion 10 There is no relative rotational freedom between the arm portion 10 and the second arm portion 11, and the axis lines 101, 111 of the first arm portion 10 and the second arm portion 11 are arranged at about 90 degrees to each other, and the connecting member 12 has a second The first connecting surface 121 and the second connecting surface 122, the connecting member 12 is in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com