A stepping tin feeding mechanism for electric soldering iron

A technology of tin feeding mechanism and electric soldering iron, which is applied in the direction of soldering iron, tin feeding device, metal processing equipment, etc. It can solve the problems of complex structure of electric transmission gear, low reliability, and stuck solder wire, etc., and achieve high reliability, The effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below.

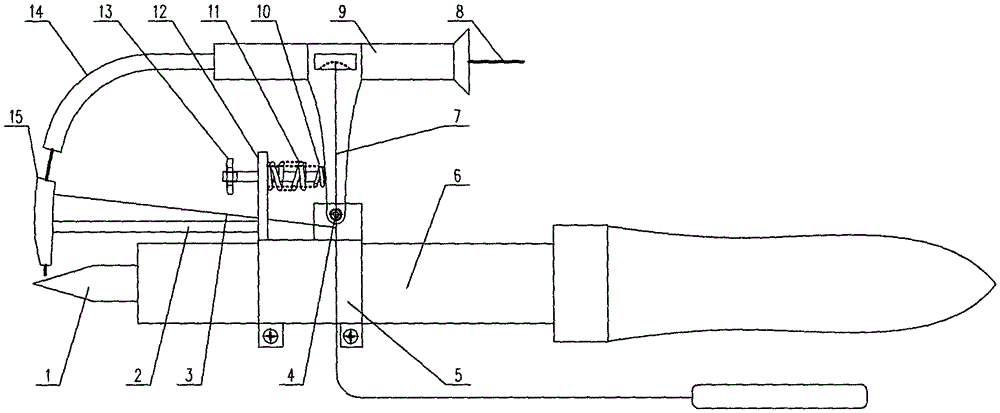

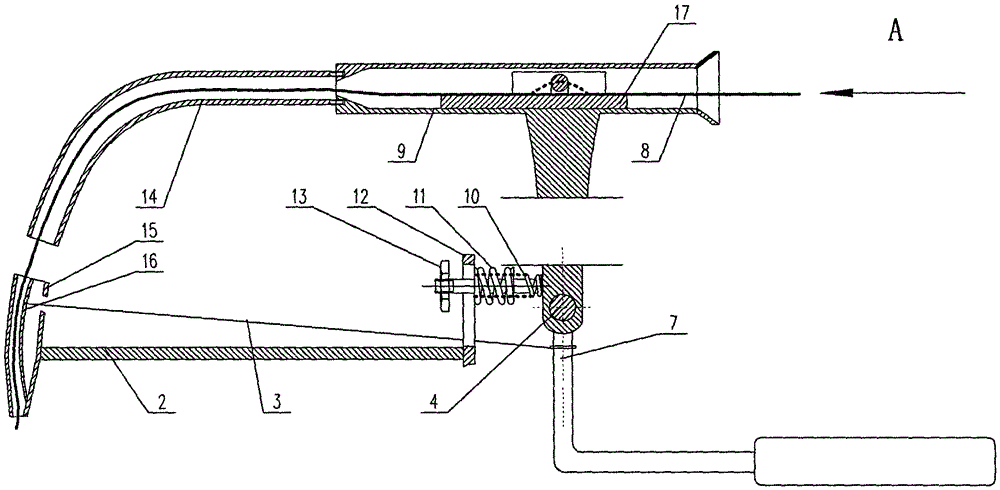

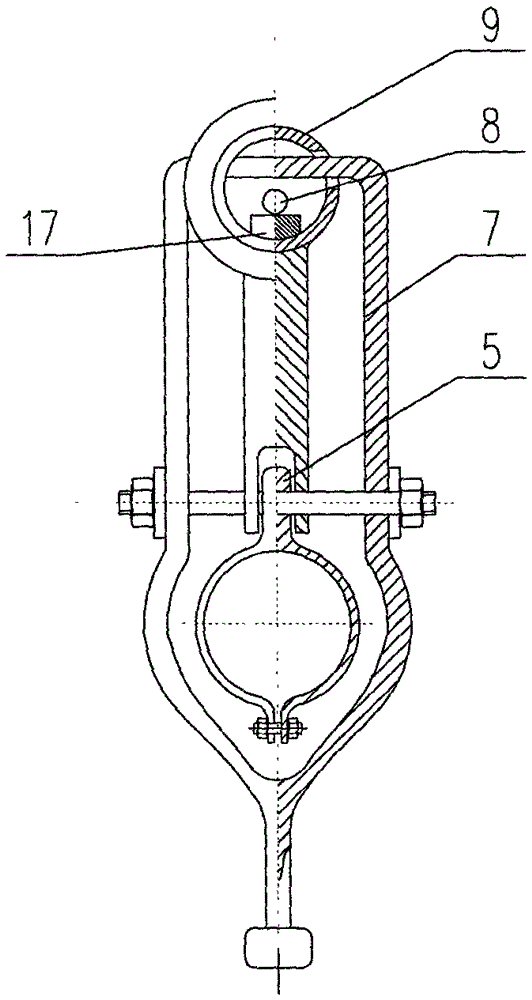

[0031] The specific implementation of the device of the present invention is shown in the accompanying drawings. The device mainly includes: an ordinary electric soldering iron 6, a trigger link 7, a tin feeding support 9, a return spring 10 of the tin delivery support, a return spring 11 of the trigger link, a guide tube 14, Align head 15.

[0032] During the actual welding operation, the operator first passes the solder wire 8 through the gap between the trigger link 7 and the support table 17 and passes out along the guide tube 14 and the alignment head 15, and then holds the welding torch with the index finger and middle finger of the right hand Handle 6, thumb presses the handle of the trigger link 7, the upper end of the trigger link 7 rotates counterclockwise and clamps the solder wire 8 together with the support table 17 in the tin feeding bracket 9 and simultaneously drives the tin feeding bracket 9 aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com