Graphite spray-coating device for warm forging operation and using method of graphite spray-coating device

A technology of spraying device and graphite, which is applied in the field of metal extrusion processing equipment, can solve the problems of insufficient spraying mold surface, high mold manufacturing cost, frequent mold replacement, etc., and achieves the improvement of repeated utilization rate, reduction of mold cost, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

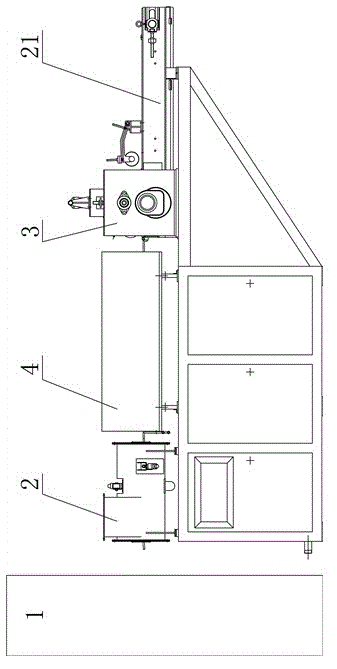

[0013] A graphite spraying device for warm forging operations, comprising a forging press 1, a graphite spraying machine 2, a conveying track 21, a nip roller feeder 3 and a preheating induction furnace 4, such as figure 1 As shown, the specific structure is:

[0014] The graphite spraying machine 2 is arranged on both sides before the feeding port of the forging press 1, and the graphite spraying machine 2 is provided with a conveying track 21, and the conveying track 21 penetrates from the feeding port of the graphite spraying machine 2, and the transportation outside the graphite spraying machine 2 The track 21 connects the pinch roller feeder 3 and the preheating induction furnace 4 in turn, and the conveying track 21 in the graphite spraying machine 2 is wave-shaped.

[0015] When this embodiment is used, follow the steps below:

[0016] The parts are clamped by the nip roller feeder 3 and sent to the preheating induction furnace 4 through the conveying track 21 to be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com