Fully-sealed power distribution cabinet

A power distribution cabinet, fully sealed technology, applied in the substation/power distribution device shell, busbar/line layout, etc., can solve the problems of dust accumulation in the power distribution cabinet, time-consuming, obstacles, etc., to achieve convenient adjustment, easy search, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

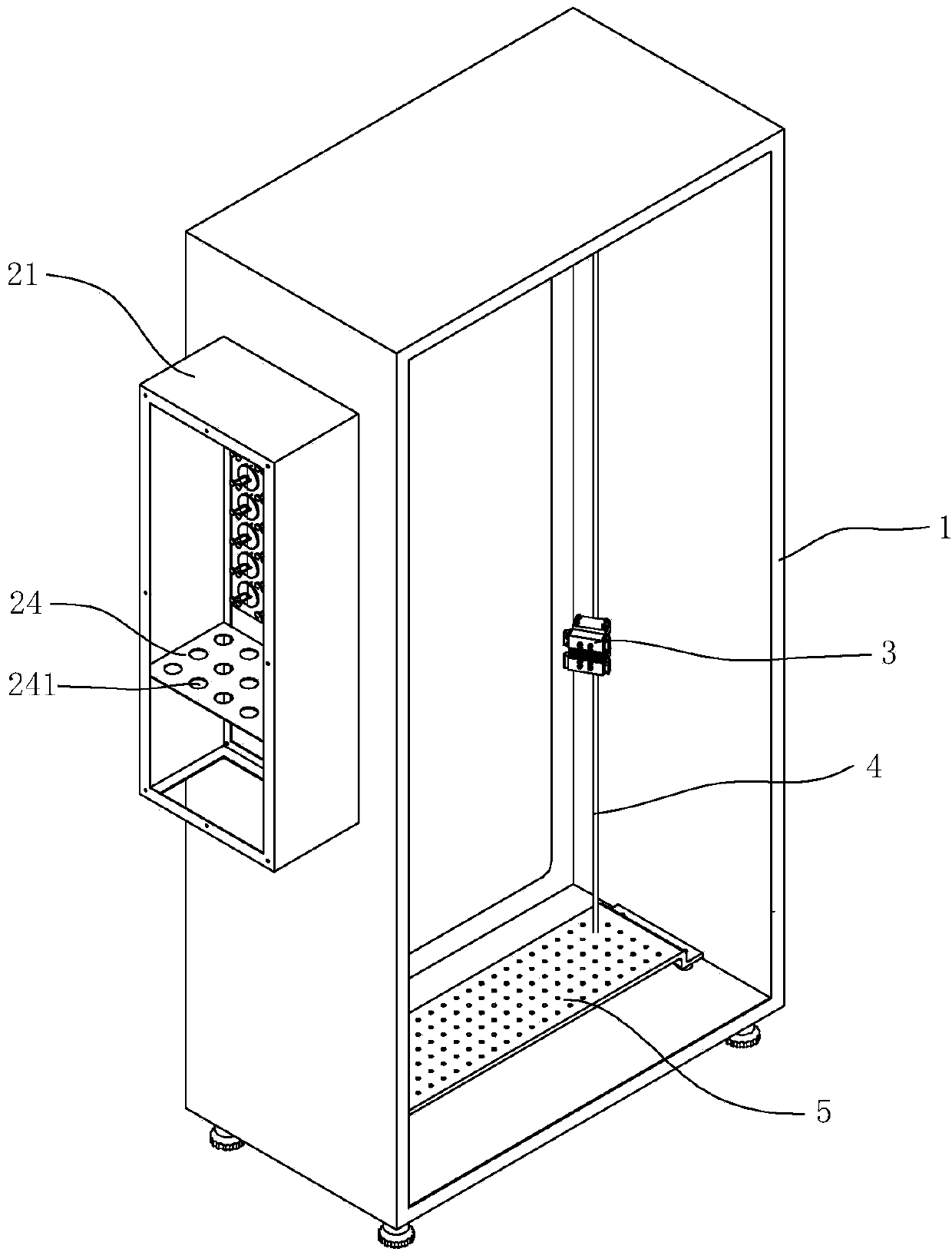

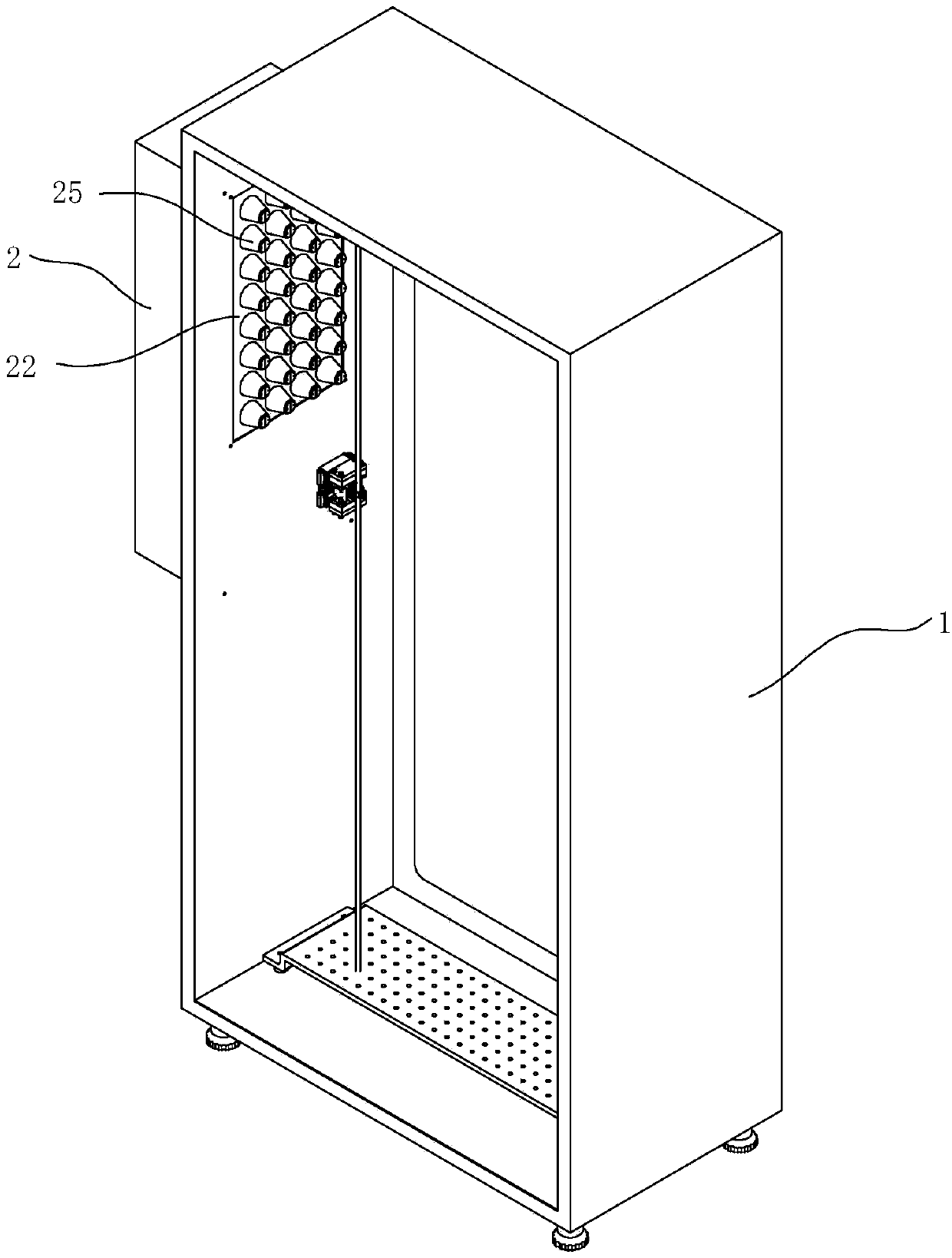

[0027] see Figure 1 ~ Figure 3 , a fully sealed power distribution cabinet, including a cabinet body 1 and a cabinet door (not shown), when the cabinet door is closed, it is sealed with the cabinet body 1 with a rubber seal. The side of the cabinet body 1 is provided with an incoming line box 2 . The terminal box 2 includes a box body surrounded by four side plates 21, a bottom plate 22 and a sealing plate 23 opposite to the bottom plate 22. The lower end of the terminal box 2 is open so that cables and wires enter the terminal box 2. The position corresponding to the bottom plate 22 of the incoming line box 2 is opened on the side wall of the cabinet body 1, so that the bottom plate 22 is installed. A pipe joint mounting plate 24 is arranged inside the wire inlet box 2, and a plurality of mounting holes 241 are opened on the pipe joint mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com