Biological Sample Processing System

A biological sample and processing system technology, applied in the field of biological sample experimental devices, can solve the problems that the manual chromosome disperser cannot meet the demand, high production, use and maintenance costs, complex structure, etc., to ensure the degree of chromosome dispersion and the accuracy of humidity control High, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

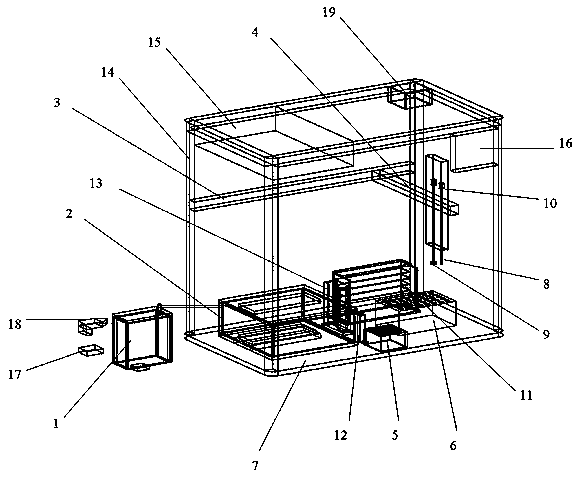

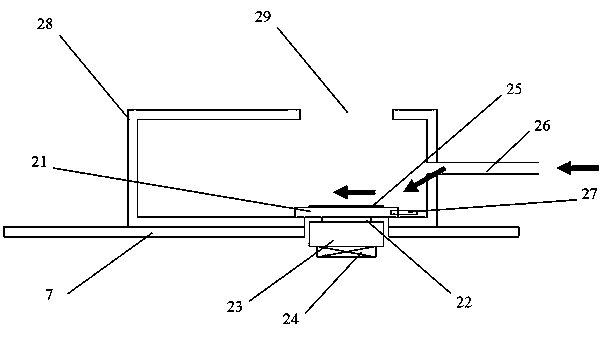

[0036] In this example, see figure 1 , a biological sample processing system, including a system base plate 7, a glass slide placement platform 21, a sample pool 6, a biological sample dropping device and a sample processing chamber, the slide glass placement platform 21 is fixedly installed on the system base plate 7, and A slide glass 25 is set on the slide glass placement platform 21, and also includes a control system 15 and a man-machine interface 16. The control system 15 is a single-chip microcomputer, and the control system 15 transfers the biological sample to be processed to the loading plate by controlling the biological sample dropping device. On the surface of the glass slide 25, the user realizes information interaction with the control system 15 through the man-machine interface 16, the man-machine interface 16 is connected with the control system 15 through a communication connection line, and the parameters of the sample processing process are set through the m...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, especially in that:

[0056] In this embodiment, the waste gas adsorption device 19 is composed of a filter and an exhaust fan to realize the automatic adsorption of the gas generated in the biological experiment process. The filter is provided with an adsorbent filter layer, and the adsorbent used is soda lime. The device 19 is located above the sample processing system and consists of a fan, adsorbent and a casing. The processed samples are generally cell suspensions fixed by methanol and acetic acid. The samples processed by droplet contain volatile organic solvents such as methanol and acetic acid. During the processing, volatile methanol and acetic acid volatile gases will be released into the system. Internally, there are adverse effects on the unit itself, the operator and the environment. The fan of the exhaust gas adsorption device 19 pumps the air containing volatile gas into the interior of the exhaust g...

Embodiment 3

[0058] This embodiment is basically the same as the previous embodiment, and the special features are:

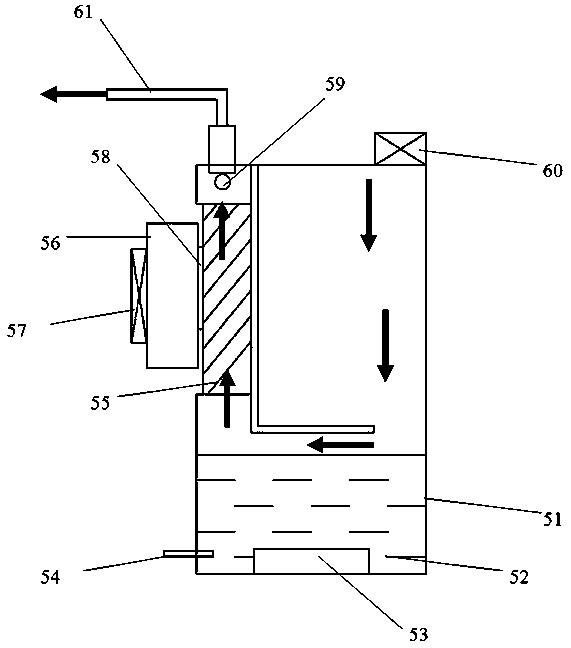

[0059] In this example, see image 3 , the humidity control device and the air flow control device of the sample processing chamber 2 are integrated into a constant humidity air flow generating device 1 outside the sample processing chamber 2, and the constant humidity air flow generating device 1 is a closed cavity, and the sample processing chamber 2 There is an air inlet 26, and the air inlet 26 of the constant humidity airflow generating device 1 communicates with the air outlet 61 of the constant humidity airflow generating device 1 through the gas delivery pipeline, and an airflow generating device 60 is set in the constant humidity airflow generating device 1 as a sample processing The airflow control device in the cavity 2 realizes the flow control of the conveying airflow. The airflow generating device 60 is an air pump. The constant humidity airflow generating dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com