Precision positioning drive-end pre-tightening device

A precision positioning and driving end technology, applied in the direction of measuring devices, electrical devices, mechanical measuring devices, etc., can solve the problem that micro-nano level changes in preload cannot be measured or feedback compensation, torque cannot be eliminated, preload accuracy and stability Unable to guarantee and other problems, to achieve the effect of simple and easy technical means, highlighting essential characteristics, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

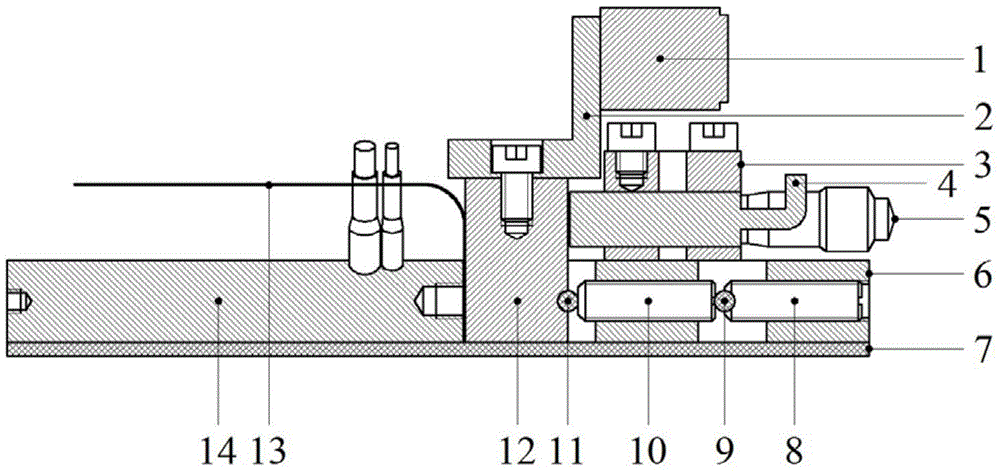

[0039] Such as Figure 1~6 shown. The precision positioning driving end pretensioning device of the present invention includes a positioning platform 6, a driver 14, a capacitive sensor 4, a capacitive sensor bracket 3, a pretensioning block 12, and a film force sensor 13;

[0040] A chute is provided in the middle of the positioning platform 6 , and the preload block 12 , the film force sensor 13 and the driver 14 are sequentially placed in the chute; the bottom of the positioning platform 6 is provided with a gasket 7 .

[0041] The capacitive sensor support 3 is fixed on the positioning platform 6, and the middle part of the capacitive sensor support 3 is opposite to the pretension block 12; the axis of the capacitive sensor support 3 is perpendicular to the axial direction of the chute;

[0042]One side of the frame body of the capacitive sensor bracket 3 is axially provided with three connecting rods 3-1 sequentially connected by compliant hinges, and the middle connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com