Intelligent pneumatic supporting leg type vibrating anchor drilling rig capable of recognizing looseness range of surrounding rock

A bolt-rod drilling rig and outrigger-type technology, which is applied in drilling equipment, earthwork drilling, drilling measurement, etc., can solve problems such as automatic identification of difficult-to-loose surrounding rock ranges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

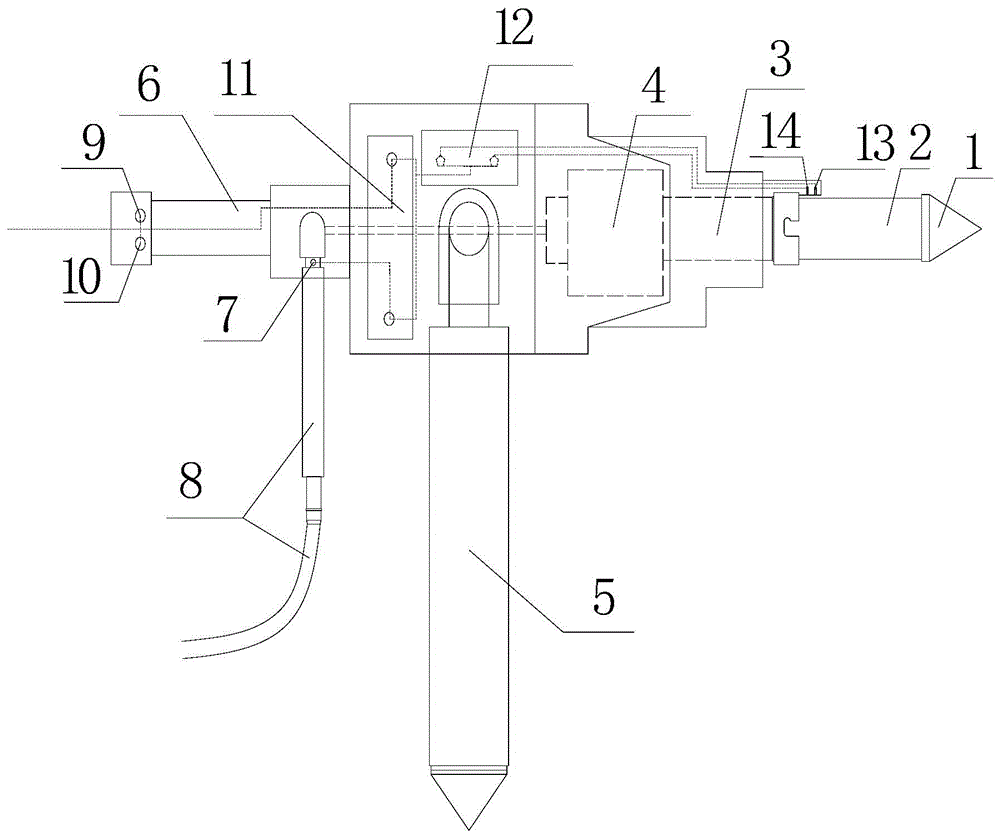

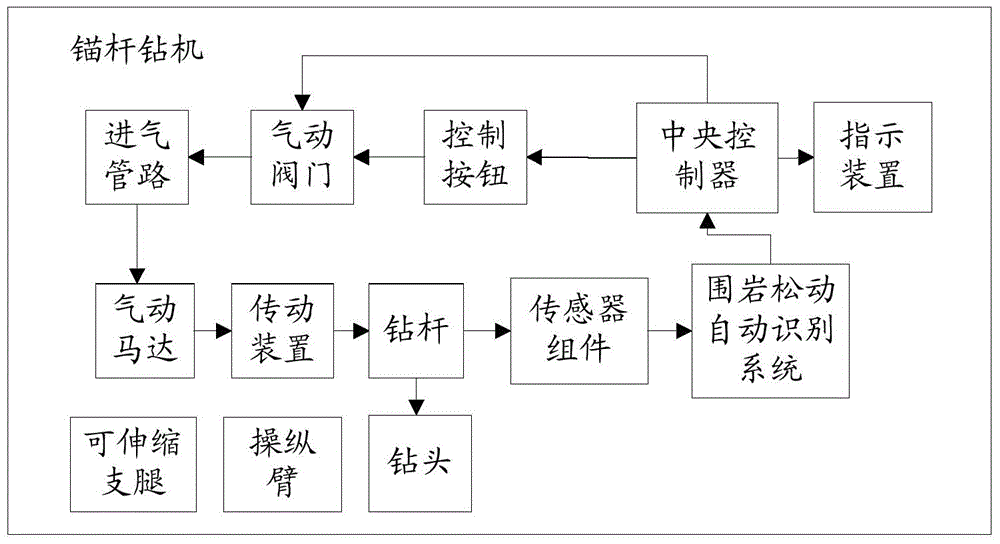

[0033] See figure 1 , The first embodiment of the present invention provides an intelligent pneumatic outrigger type vibration bolting rig that can identify the range of surrounding rock loosening. The intelligent pneumatic outrigger type vibration bolting rig that can identify the range of surrounding rock loosening is in turn from left to right It includes a drill bit 1, a drill rod 2, a transmission device 3, a drill pipe pneumatic motor 4, and a retractable air leg 5. The intelligent pneumatic outrigger type vibratory bolting rig that can identify the range of surrounding rock loosening is also provided with a control arm 6 on the side , Pneumatic valve 7, air intake pipe 8 connected to said pneumatic valve 7, and indicator light 9 and control button 10 installed on said control arm 6; wherein:

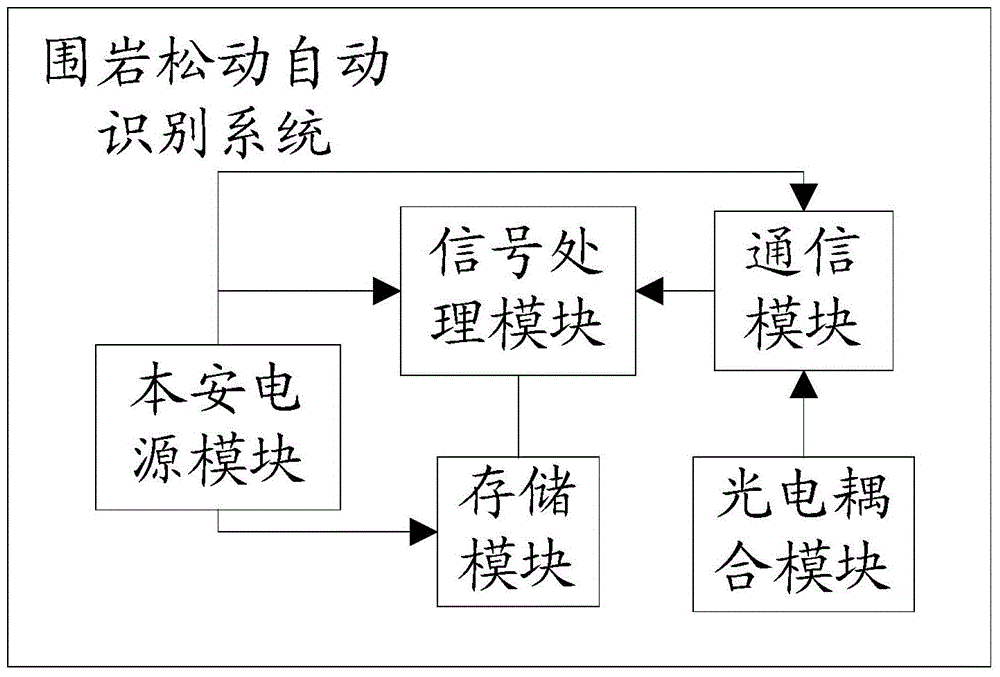

[0034] The sensor assembly is laid on the bolting rig and electrically connected with the automatic identification system for surrounding rock looseness; the central controller 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com