Bottom plate structure of steam-powered ironing device

The technology of ironing equipment and soleplate is applied in the field of soleplate structure of steam ironing equipment, which can solve the problems affecting the function and sales of the iron, the effect of ironing clothes is not good, and the temperature is lowered to about 140 degrees Celsius, etc., so as to improve the uniqueness, Good ironing effect and improved satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

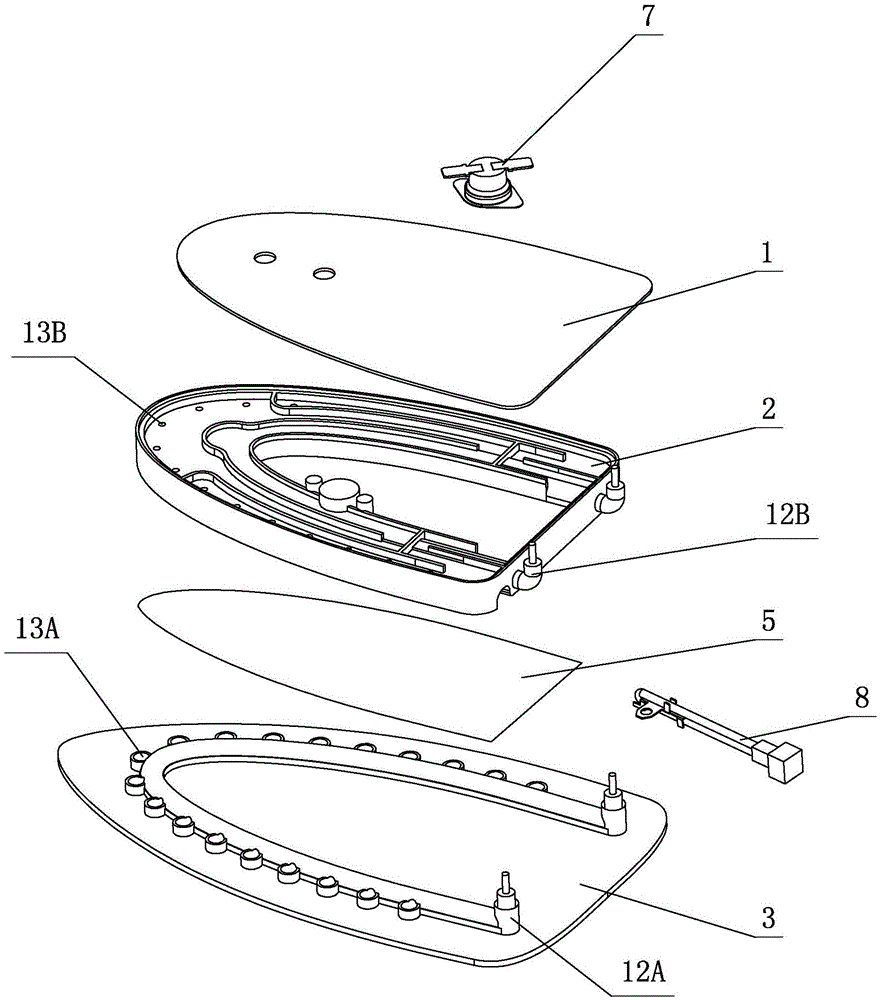

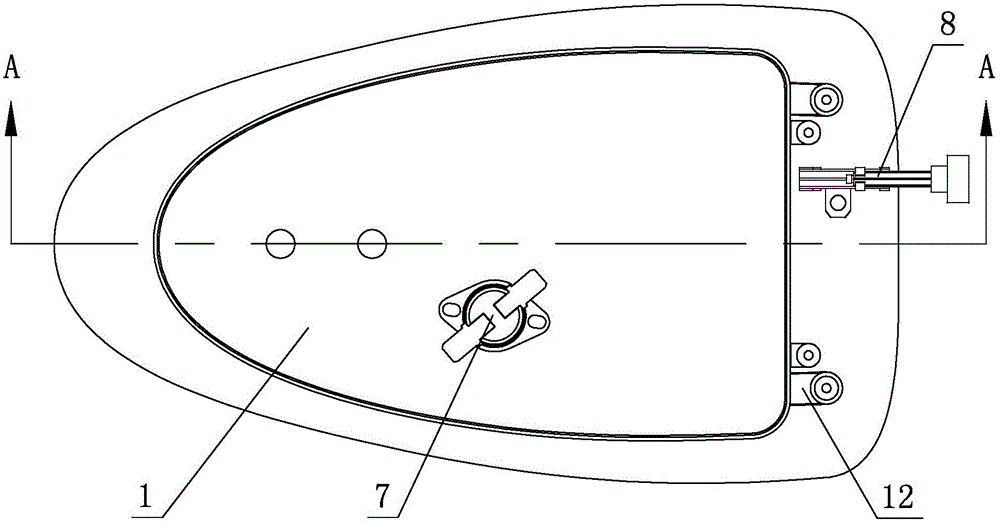

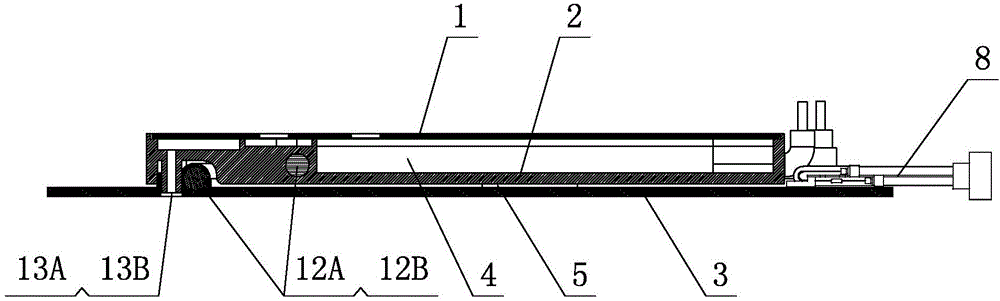

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0019] see Figure 1-Figure 3 , the bottom plate structure of the steam ironing equipment, including:

[0020] The first bottom plate 2, the first bottom plate 2 includes a first heating device 12B and a vaporization chamber 4, and has at least one first steam outlet 13B, and a first temperature control device 7 is provided on the first bottom plate 2;

[0021] The second bottom plate 3, the second bottom plate 3 includes a second heating device 12A and at least one second steam outlet 13A, and a second temperature control device 8 is provided on the second bottom plate 3;

[0022] The temperature between the first bottom plate 2 and the second bottom plate 3 is independent through the heat insulation device 5, the first bottom plate 2 is controlled and heated by the first temperature control device 7, and the second bottom plate 3 is controlled by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com