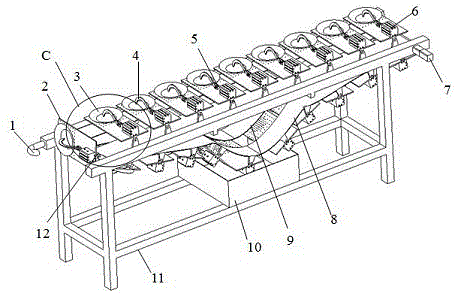

Conveyor belt type automatic glazing device

The technology of a conveyor belt and a conveyor belt two is applied in the field of automatic glazing devices, which can solve the problems of high labor intensity of workers, poor glazing quality and low efficiency, and achieves simple bowl blank clamping mechanism, glazing quality assurance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

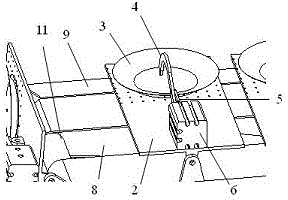

[0027] Such as figure 2 , 3 As shown, first is the clamping process of the bowl blank 3, the bowl blank clamping mechanism moves to the A station, at this time, the piston rod of the clamping cylinder 6 is pushed out to drive the pull rod 5, the pull rod 5 makes the pressure rod 4 swing, and the pressure rod 4 The top of the top contacts the bottom of the bowl blank 3, and the bowl blank 3 is pressed in the circular groove on the rocking plate 2 so that it cannot slide, and the clamping process of the bowl blank 3 is completed.

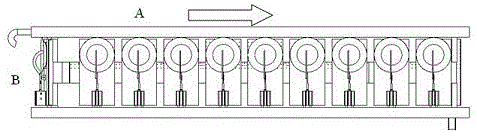

[0028] control figure 1 After the bowl blank 3 is clamped, the low-speed motor 7 rotates, the low-speed motor 7 drives the conveyor belt one 8 and the conveyor belt two 9 to rotate on the support 11, and the bowl blank clamping mechanism is hinged with the hinged boss on the conveyor belt one 8 and the conveyor belt two 9, And with the rotation of conveyor belt 1 8 and conveyor belt 2 9, the position changes continuously. When the bowl blank clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com