Robojelly driven by axially parallel annular shape memory alloy

A technology of memory alloy and memory alloy wire, which is applied in the direction of non-rotating propulsion components, can solve the problems of complex structure and small movement range of bionic machine jellyfish, and achieve simple control, high bionic propulsion effect, and obvious bionic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

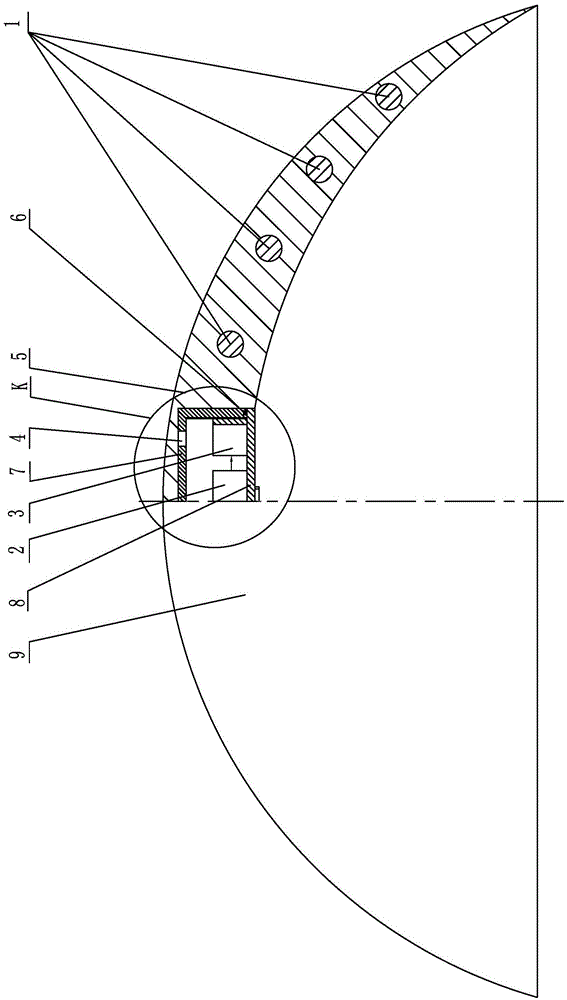

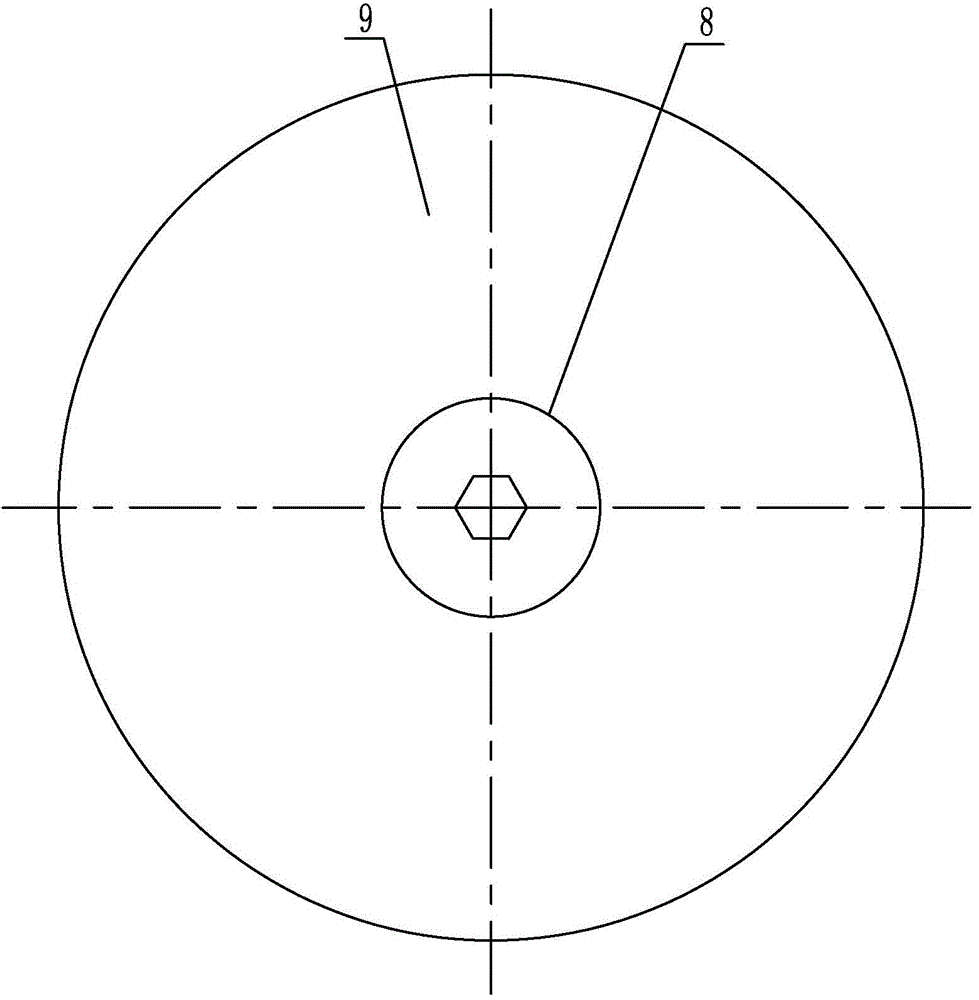

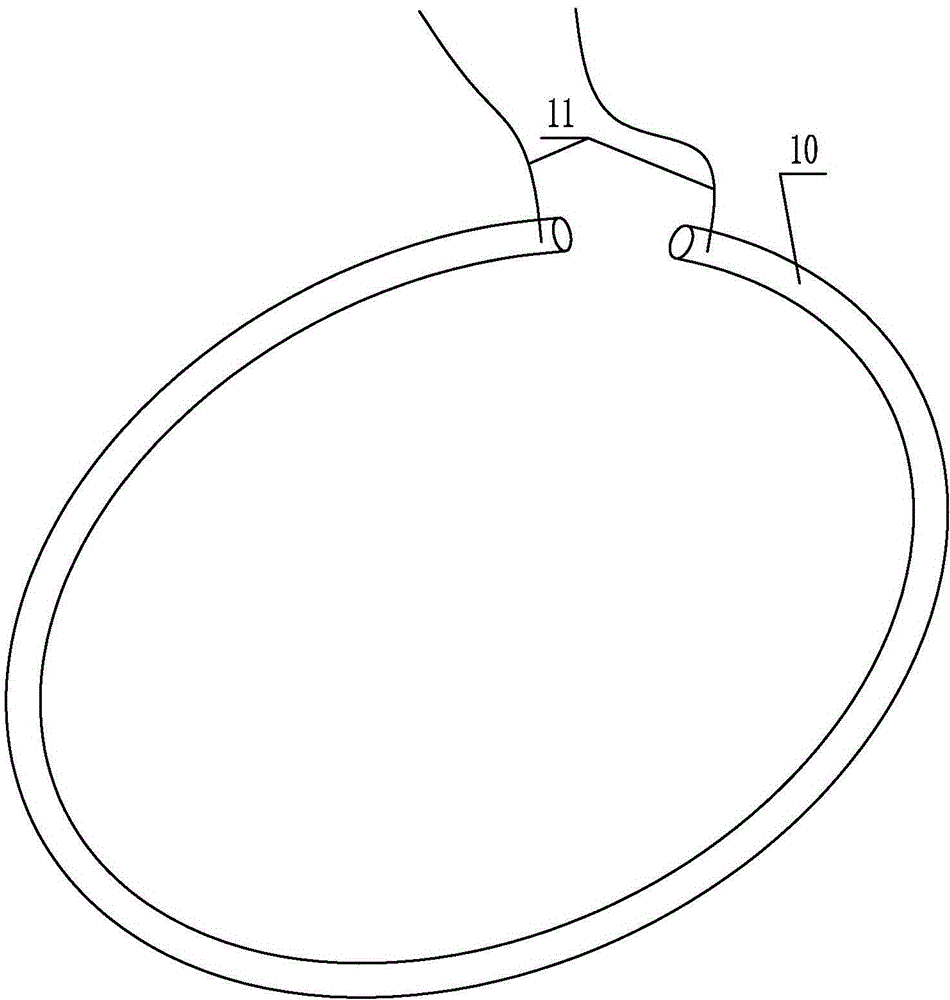

[0010] Specific implementation mode one: combine Figure 1-Figure 5 Explain that the axially parallel annular shape memory alloy driven robotic jellyfish of this embodiment includes a power supply 2 and a control and communication module 3, and it also includes a flexible shell 5, a cylindrical abdominal cavity 7, a rotator base 8 and several annular shape memory alloys. The driving part 1; the outer contour of the flexible shell 5 is hemispherical, and each annular shape memory alloy driving part 1 is composed of a shape memory alloy wire 10 and an open annular flexible tube 12 wrapped around the shape memory alloy wire, and several annular shape memory alloy driving parts The components 1 are arranged side by side, the axial direction of several annular shape memory alloy driving components 1 is parallel to the axial direction of the flexible housing 5, and several annular shape memory alloy driving components 1 are respectively embedded in the peripheral side of the flexible...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 Note that the flexible shell 5 in this embodiment is a silicone flexible shell. With such arrangement, the flexible shell is light and easy to control the shrinkage range, thereby realizing the advancement of the jetting speed. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 Note that the cylindrical abdominal cavity 7 in this embodiment is made of plexiglass. With such arrangement, the cylindrical abdominal cavity is transparent, light, cheap and easy to obtain, and is convenient for storage of power supply, control and communication modules. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com