A liquid silicone injection mold

An injection mold and liquid silicone technology, which is applied in the field of liquid silicone injection molds, can solve the problems of difficulty in feeding amount, increase the difficulty of processing technology, and increase the difficulty of precise control of the amount of glue feeding, and achieve the effect of reducing the control accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with preferred embodiments.

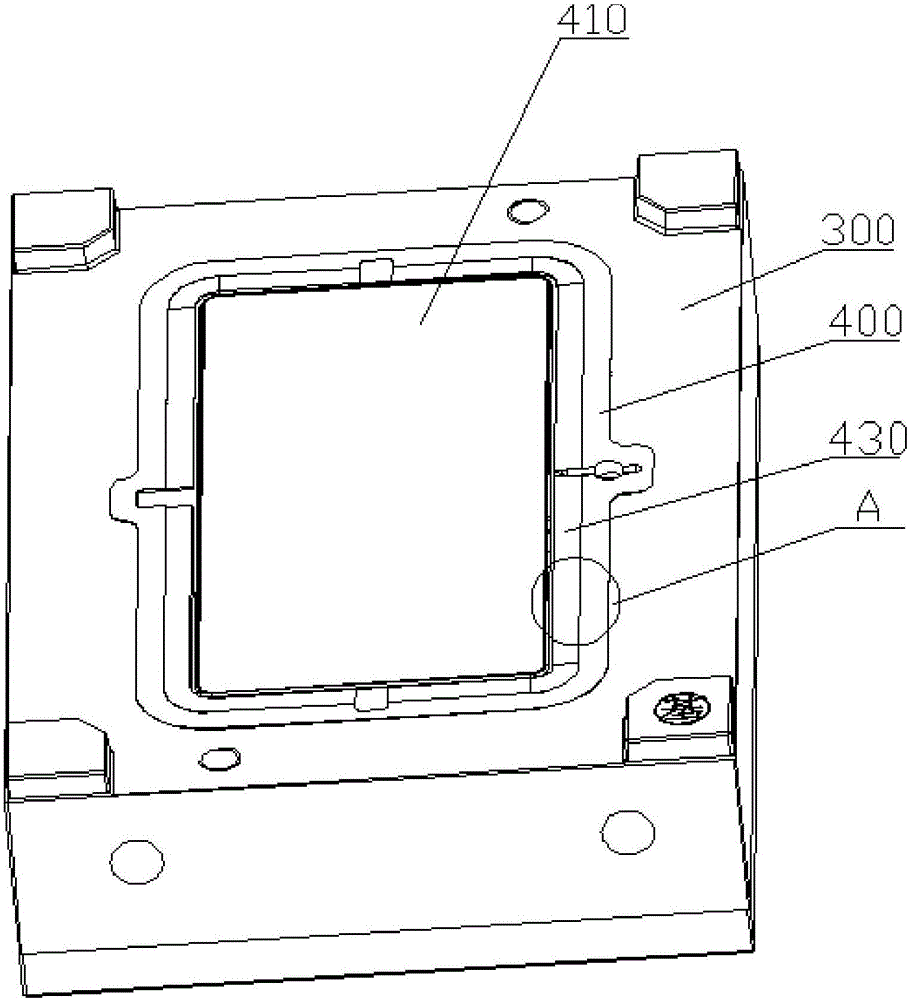

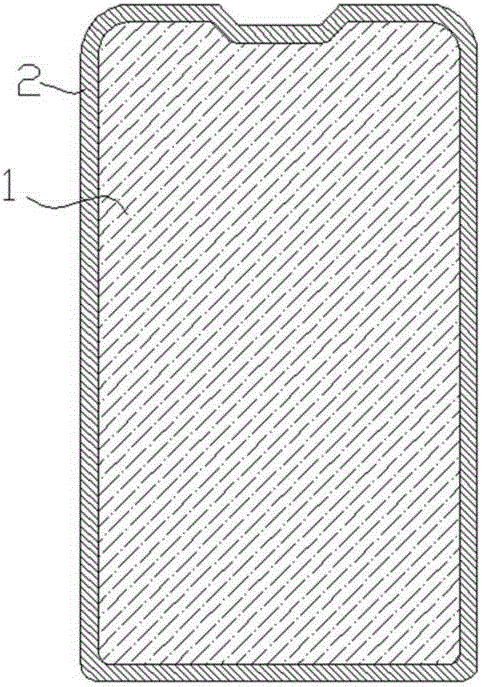

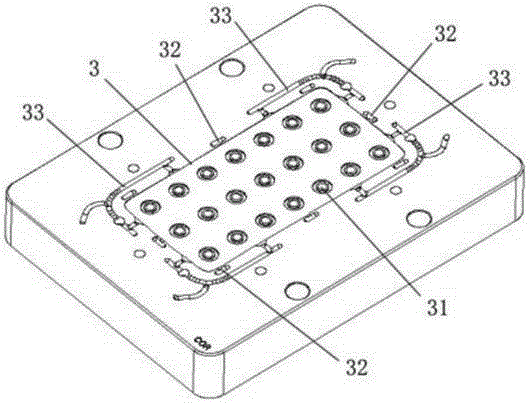

[0024] like Figure 3-6 As shown, the liquid silicone injection mold of this embodiment is a liquid silicone injection mold used to form a rubber edge structure on the side of the substrate, for example: to form a rubber edge on the side of the electronic product display glass, back shell and other substrates For waterproof, shockproof and dustproof. The injection mold includes a front template 100 , a front mold core 200 fixed in the front template, a rear template 300 , a rear mold core 400 fixed in the rear template, and a pouring sleeve 500 .

[0025] The rear mold core 400 is provided with a substrate fixing groove 410 , a pouring groove 420 and a glue overflow area 430 .

[0026] The substrate fixing groove is used to fix the substrate 001 with 410. After the substrate 001 is fixed, there is a predetermined interval between the side of the substrate 001 and the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com