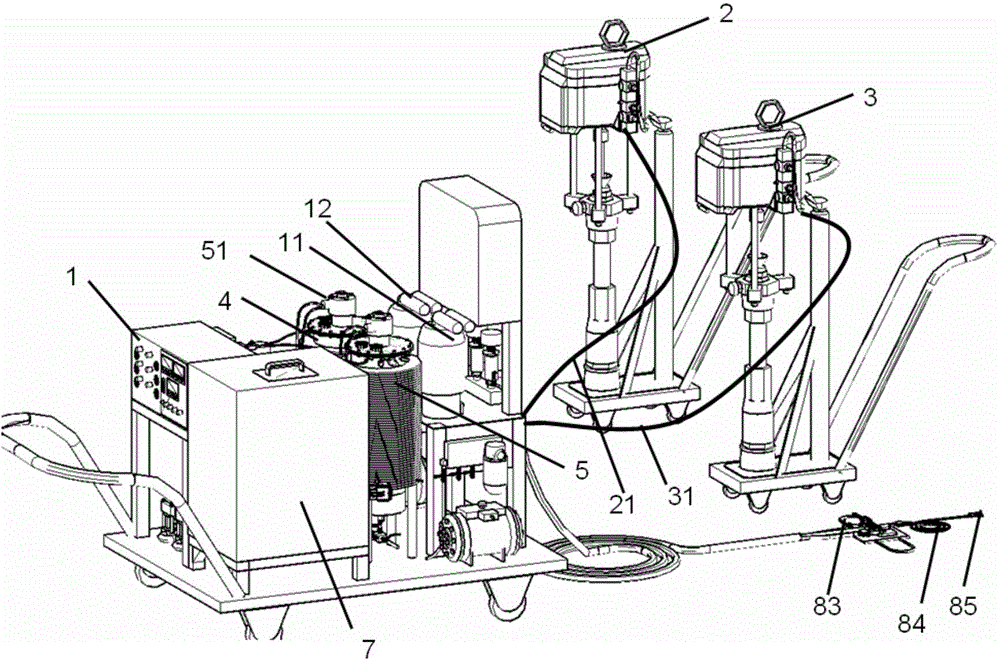

Dual-component high-pressure proportion-adjustable fire retardant coating spraying device

A technology of fire retardant coating and spraying equipment, applied in spraying device, liquid spraying device and other directions, can solve the problems of poor adaptability, increase the cost of accessories consumption, inconvenient on-site operation, etc., achieve reasonable equipment structure design, better atomization effect, The effect of saving heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

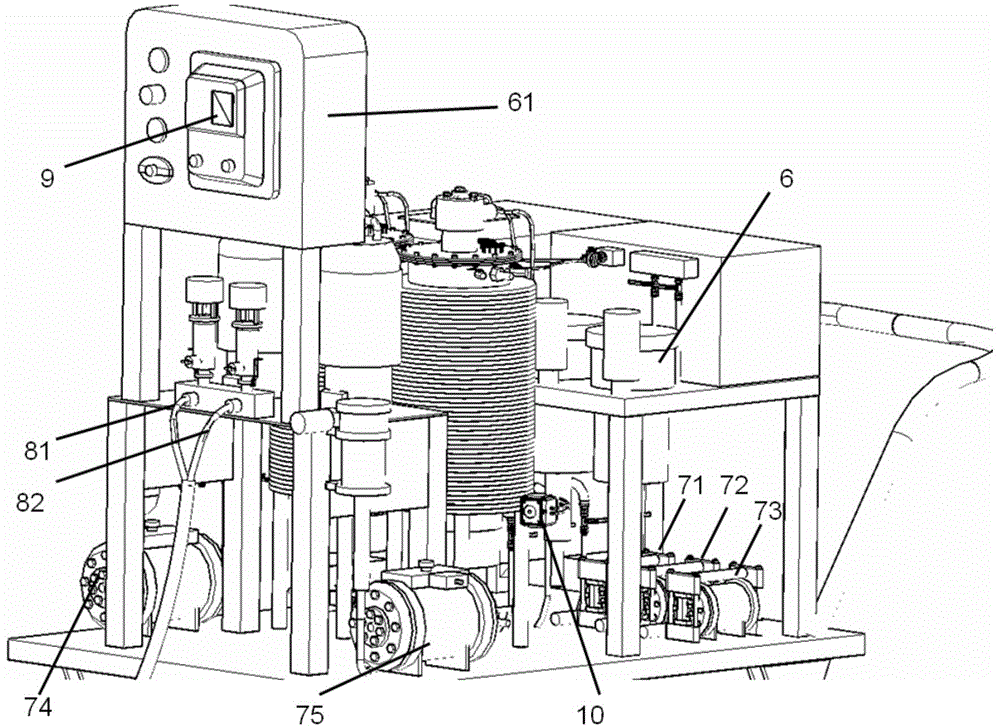

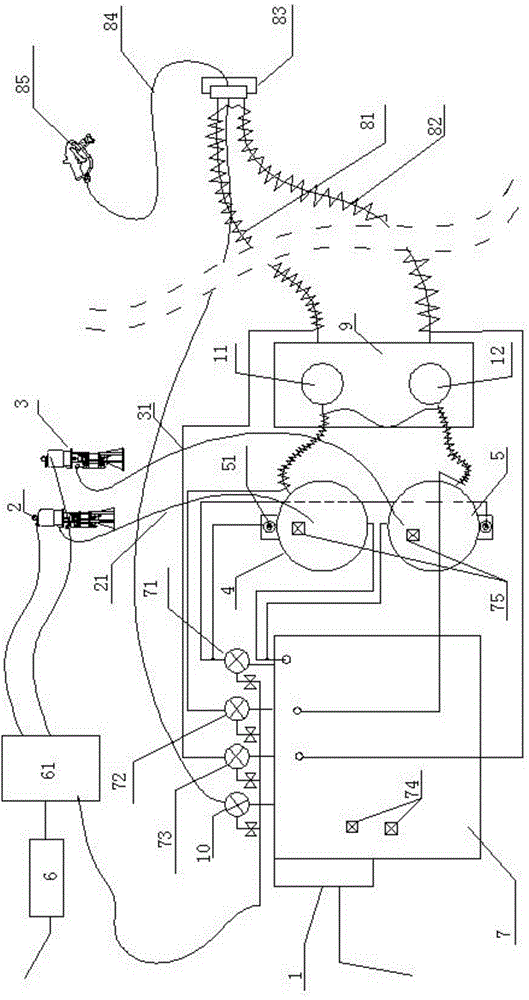

Method used

Image

Examples

Embodiment

[0034] 1. Equipment startup: before operation, first connect the equipment power supply (220V) and gas source (0.7MPa, flow rate ≥ 5m 3 / min).

[0035] 2. Feeding the paint bucket:

[0036] Connect the air regulators on component A paint feed pump 2 and B component paint feed pump 3 to the output of the main air supply pump 6 through air pipes, and turn on the A component paint feed pump 2 and B component The main air switch of the paint feeding pump 3, adjust the air regulator, and gradually increase the air pressure, and the hydraulic cylinders of the two component paint feeding pumps respectively lift the two-component paint siphon discs to the highest point, and put them in the barrel. The A-component paint and the B-component paint are respectively placed under the respective paint siphon pans, and the air pressure regulator is adjusted so that the feed port of the A-component paint bucket 4 passes through the first high-pressure insulation hose 21 and the A-component pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com