Hydrodynamic retarder

A technology of hydraulic reducer and container, applied in the field of hydraulic reducer, can solve the problems of manufacturing cost and cost of the reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

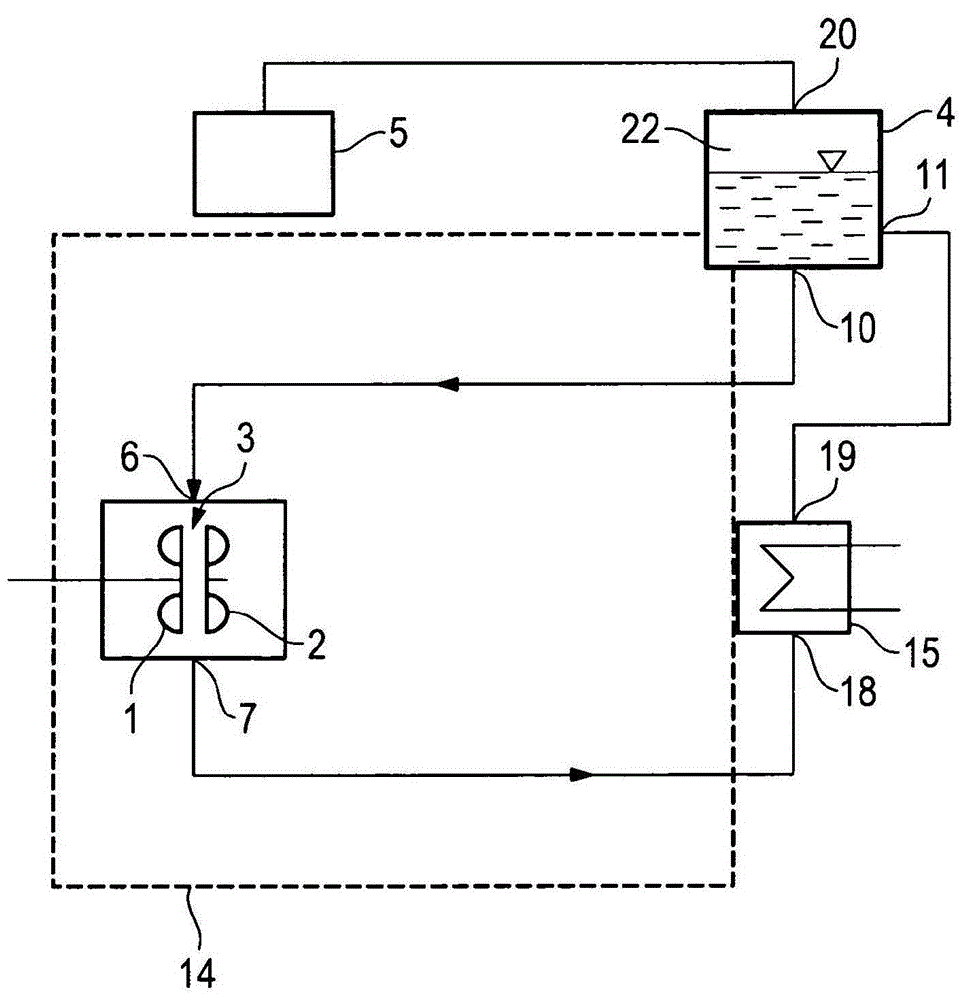

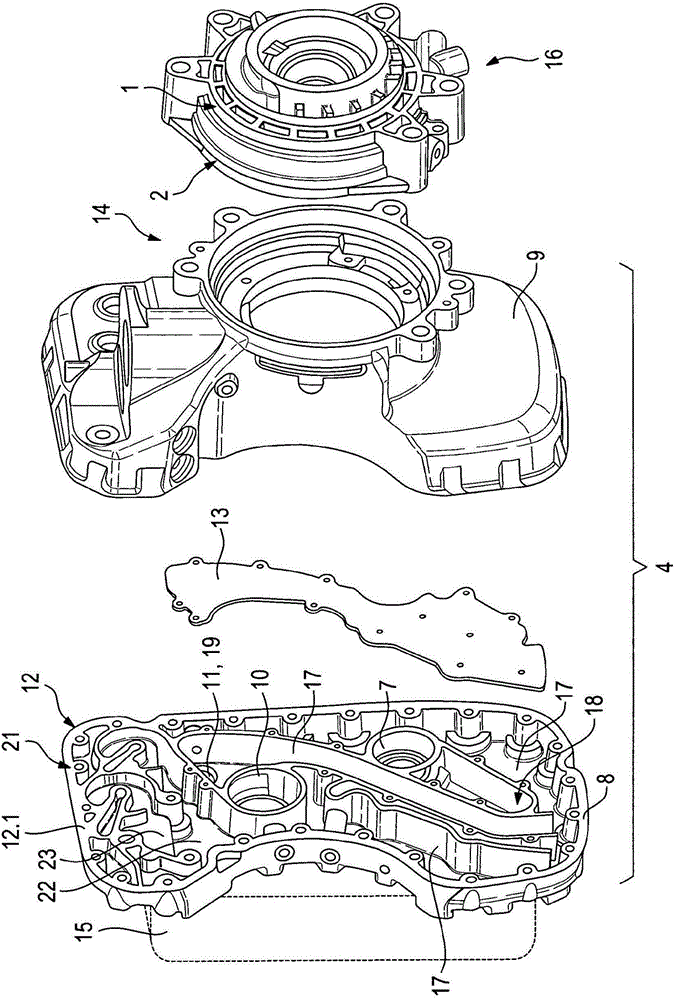

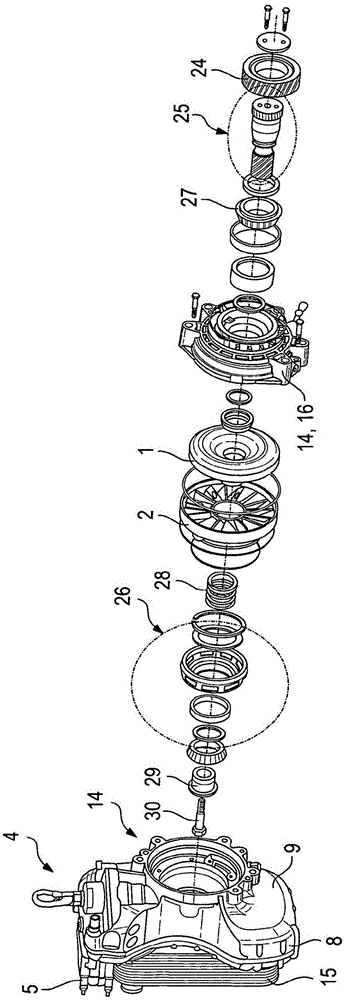

[0030] figure 1 A schematic diagram of a hydrodynamic retarder arranged in an external cooling circuit is shown. The latter consists of a bladed and rotating primary wheel, designated rotor 1 , and a stationary, non-rotating, also bladed secondary wheel, designated stator 2 . The rotor 1 and the stator 2 jointly form an annular working chamber 3 . Furthermore, a working medium container 4 is provided for storing working medium that is temporarily not in the working chamber 3 . Oil, water or a water mixture can be used as the working medium. The external cooling circuit shown can at the same time be the cooling circuit of a vehicle such as a truck or a rail vehicle, so that the cooling medium of the cooling circuit is at the same time the working medium of the hydrodynamic retarder.

[0031] The working medium container 4 includes an outlet 10 , which is connected to the first working medium connection 6 via a drain connection for conveying the working medium from the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com