Adaptive led current ripple elimination circuit

A technology of current ripple and circuit elimination, applied in electric lamp circuit layout, electric light source, lighting device, etc., can solve problems such as shortening service life, visual nerve fatigue, endangering human health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings and embodiments.

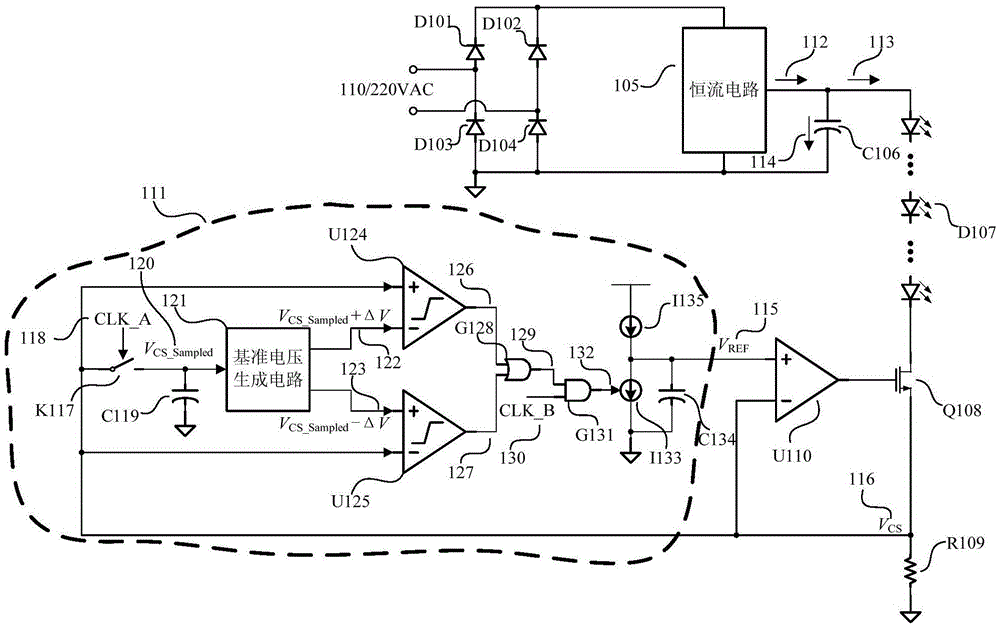

[0025] figure 2 It is Embodiment 1 of the present invention.

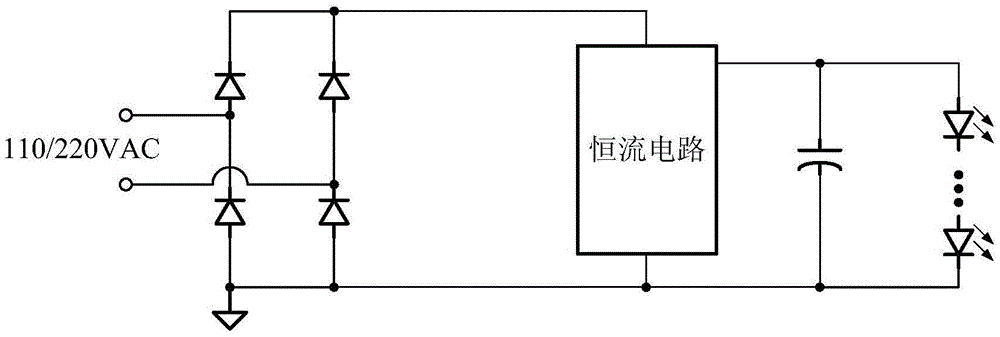

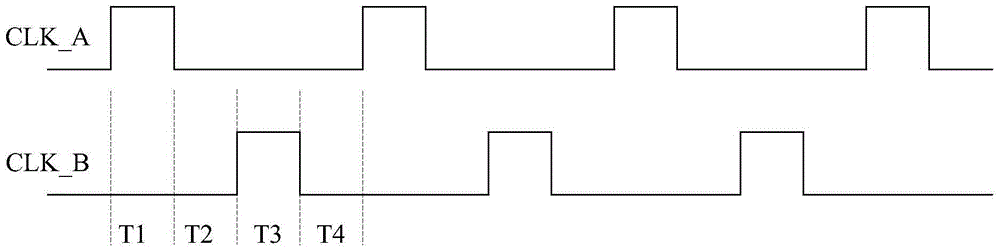

[0026] In an existing LED constant current drive circuit, the adaptive LED current ripple elimination circuit proposed by the present invention is added. Therefore, the entire LED constant current drive circuit includes rectification and filtering circuits D101, D102, D103, D104, and 105, which rectify the input AC voltage, and rectify the AC full-wave voltage with a frequency of 50 / 60Hz into an AC half-wave voltage with a frequency of 100 / 120Hz. Ripple voltage; constant current circuit 105, with power factor correction function, the output average current is constant, but there is a ripple current with a frequency of 100 / 120Hz; C106 is the output filter capacitor; D107 is a group of LED lights in series; Q108 is the power tube , can be a MOSFET. R109 is a current sampling resistor; U110 is an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com