Two-phase brushless direct current motor and sine stator

A brushed DC motor and stator technology, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., to achieve the effect of reducing the intensity of manual operation and simplifying the embedding of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

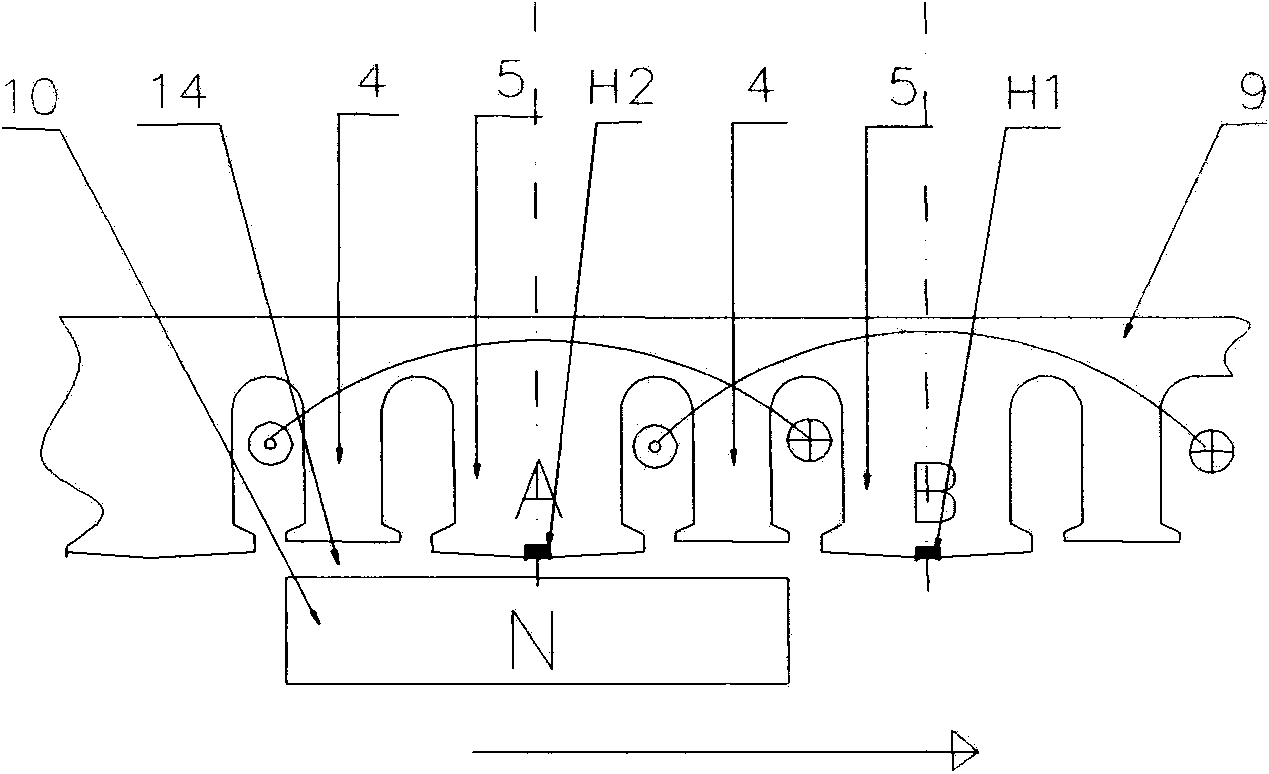

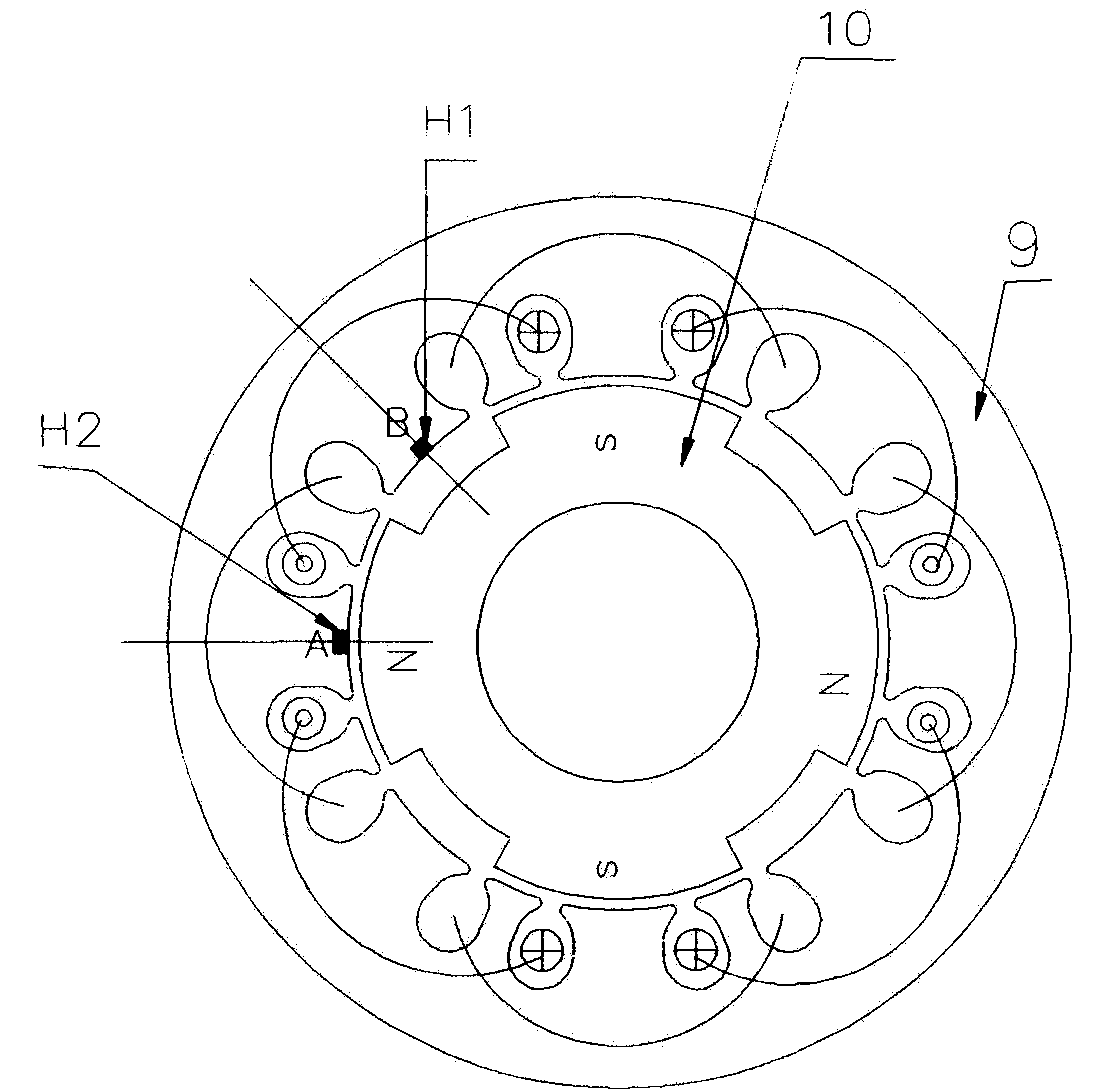

[0044] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0045] Please refer to figure 1 , Figure 1B , figure 2 , a two-phase brushless DC motor and a sinusoidal stator, including a stator 9, a rotor permanent magnetic pole 10 and the like. Among them, a Hall position sensor is installed on one side of the inner circle of the iron core of the stator 9 and the permanent magnetic pole of the rotor 10 to form a signal sampling part in the two-phase electronic commutation circuit device.

[0046] Please refer to Figure 1A , the described four-pole model of a two-phase brushless DC motor and a sinusoidal stator has sixteen teeth and sixteen slots, and the material is a high-permeability silicon steel sheet or a silicon steel sheet.

[0047] The sixteen slots are divided into eight A-phase slots 6 and eight B-phase slots 7 with equal slot areas, and A-phase windings 1 and B-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com