A mounting structure for a sub-frame and a vehicle body

A technology for mounting structures and sub-frames, which is applied in the connection between the body and the frame, vehicle components, transportation and packaging, etc., and can solve problems such as frictional movement, weak cooperation between the sub-frame and the mounting surface of the body, etc. Achieve the effects of increasing contact pressure, reducing assembly contact area, and firm assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated:

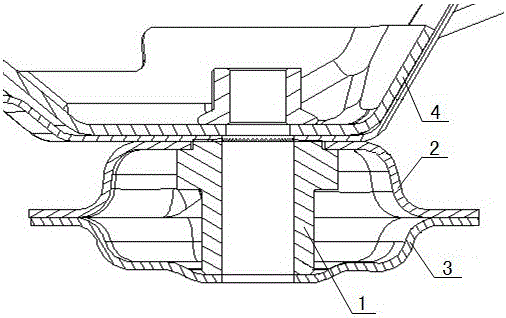

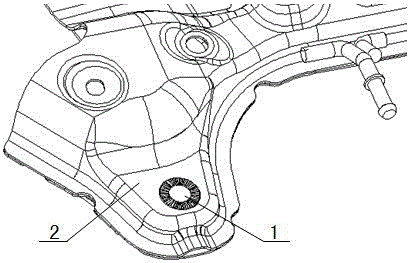

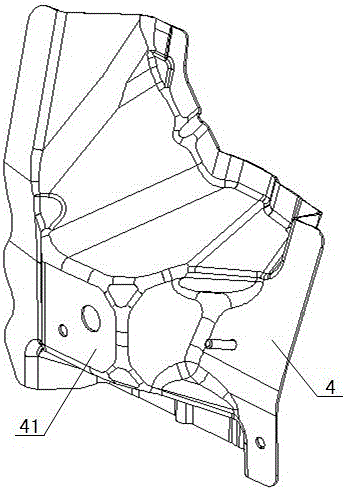

[0017] Such as Figure 1 to Figure 4 The installation structure of the subframe and the vehicle body shown includes the subframe and the side beam inner liner 4 of the engine compartment. The subframe includes the upper and lower sheet metal parts 2, 3 and the upper and lower sheet metal parts. Between the support 1, the support 1 is a hollow cylinder with a T-shaped section, a boss 11 is provided on the big end of the support, and a boss 11 is arranged on the top of the boss. There are knurling patterns 12, the knurling patterns 12 are corrugated radially outward along the center line of the support member, the inner wall of the upper sheet metal part 2 is assembled and bonded to the end surface of the big end of the support member, and the top surface of the boss 11 is as high as The outer wall of the upper sheet metal part is attached to the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com