Layered composite light acoustical material for rail train

An acoustic material, a technology for rail trains, applied in the field of materials and structures, can solve the problems of mechanical equipment wear and fatigue, reduce equipment service life, threaten the safe operation of high-speed trains, etc., achieve good thermal insulation, and improve the effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] For a more complete understanding of the invention, and to realize additional objects and advantages of the invention, a detailed description of the invention will now be made with reference to the accompanying drawings.

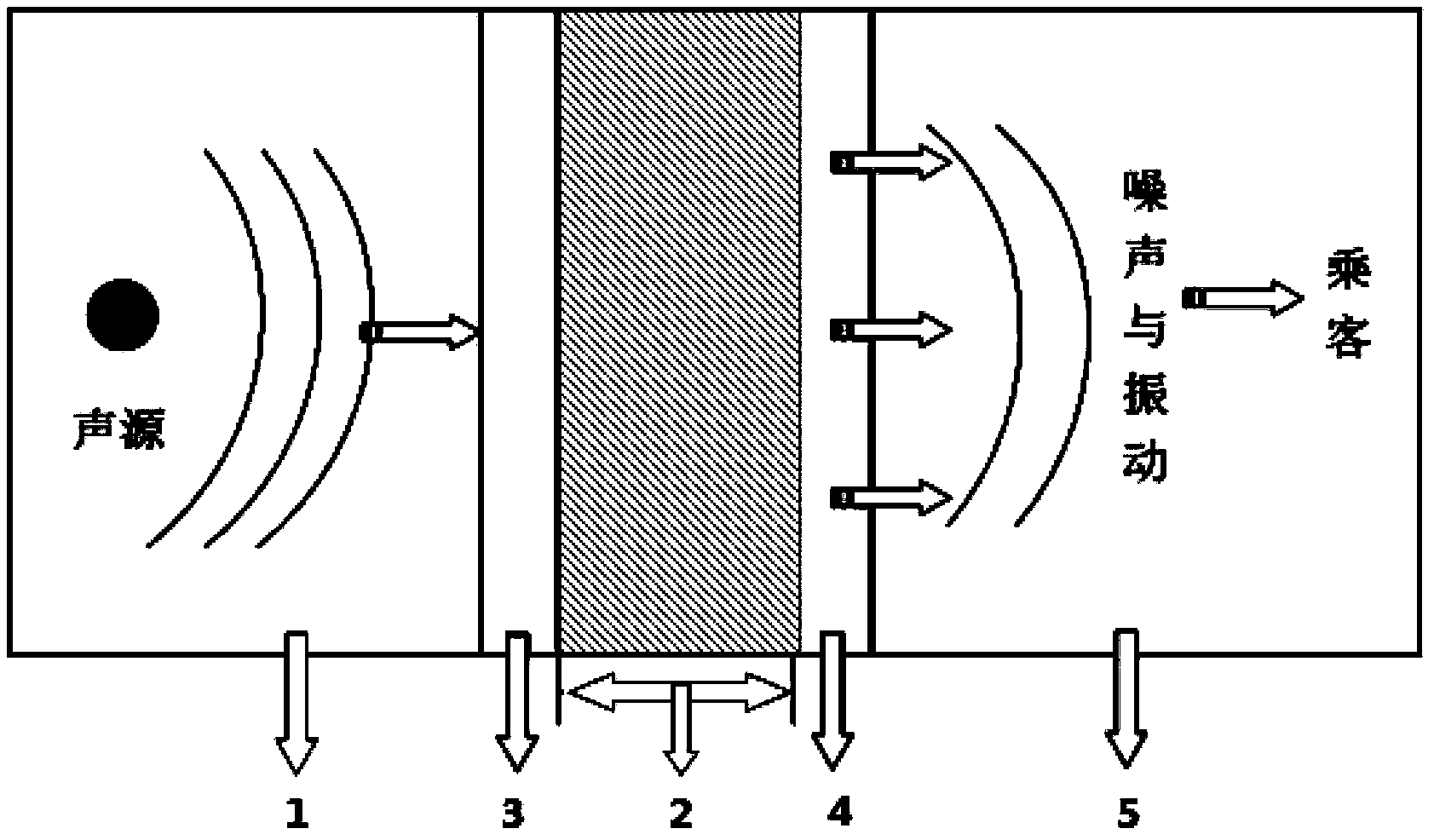

[0033] Such as figure 1 As shown, the original high-speed train compartment wall includes: the compartment exterior main structure 2 (generally made of aluminum profiles) on the side of the compartment exterior sound source 1, the compartment interior wall panel 4 located on the compartment interior space 5 side, and the New layered composite material 2 on the basis of thermal insulation and flame retardant materials in between to achieve good sound absorption, sound insulation and vibration damping performance.

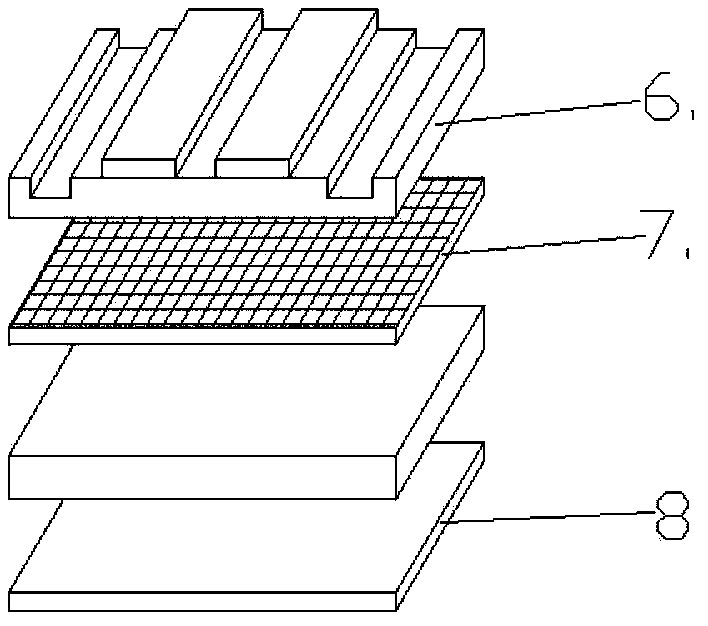

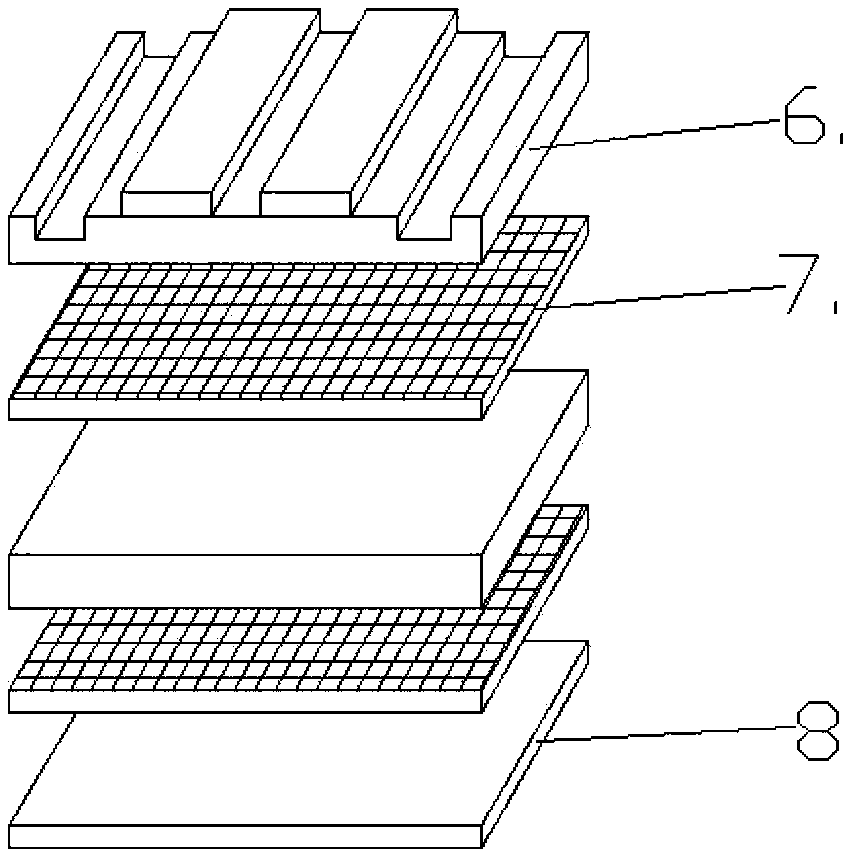

[0034] Such as figure 2 Shown, multifunctional layered composite material of the present invention comprises four layers from top to bottom:

[0035] 1. The first layer: porous material 6 (sound absorption, heat preservation)

[0036] 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com