Shaft sleeve part surface defect on-line detection method based on compressed sensing

A technology of compressed sensing and detection methods, which is applied in image data processing, instruments, computing, etc., can solve the problems of poor real-time performance, low data utilization rate, and large collection volume, achieve online detection, eliminate the influence of surface reflection, shorten the The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

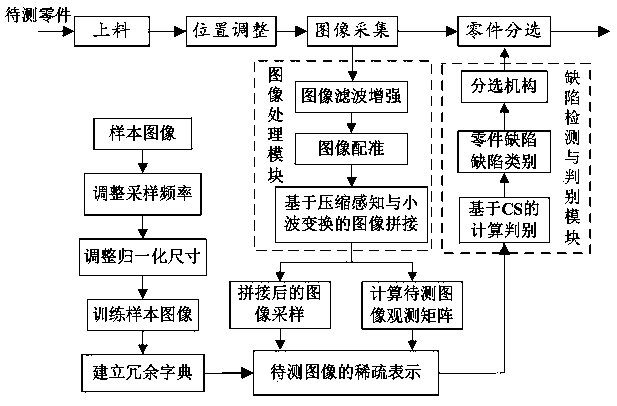

[0027] The specific embodiment of the present invention is as figure 1 shown.

[0028] This embodiment uses machine vision and compressed sensing methods to study the compressed sensing description of part surface defect images, collect typical defect part sample images, implement denoising and necessary preprocessing, adjust sampling frequency and size normalization, and train samples and establish a redundant dictionary; design an appropriate orthogonal basis decomposition matrix and a random observation matrix, select a joint orthogonal matching pursuit algorithm, and transform the solution of the minimum norm L0 into a suboptimal solution problem to reconstruct the defect image, and calculate the The sparse representation of the test image is used to identify the defects of the parts to be tested according to the established judgment and recognition standards, so as to realize the rapid detection of the surface defects of the shaft sleeve parts.

[0029] (1) Design and te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com