car shock absorber

A technology of automobile shock absorption and buffer, which is applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of affecting the shock absorption effect, easy loosening, inconvenient installation of shock absorber, etc. reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following describes the embodiments of the present invention in further detail with reference to the accompanying drawings:

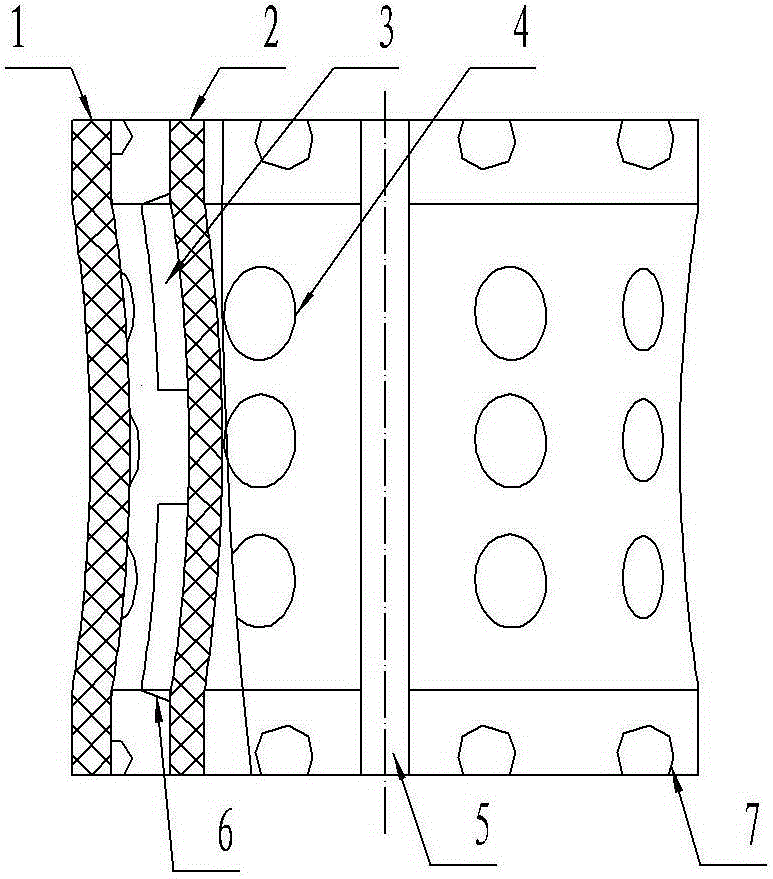

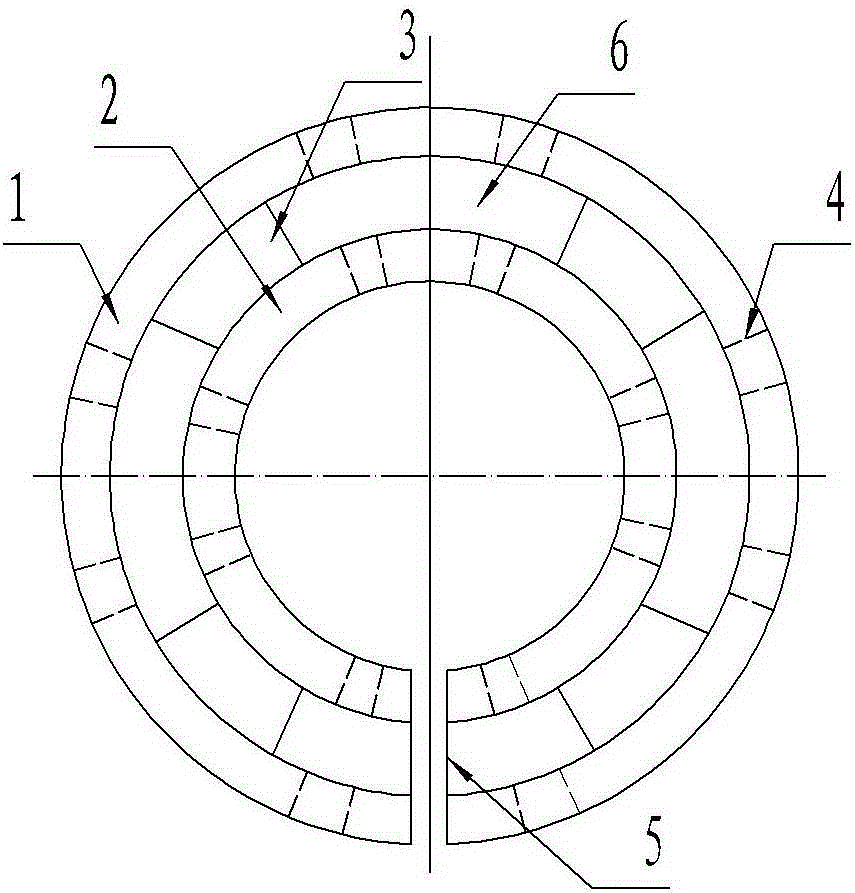

[0011] Such as figure 1 , figure 2 The automobile shock absorber shown includes a plastic part including two inner and outer ring bodies connected to each other in the middle. A connecting block 3 is arranged between the inner ring body 1 and the outer ring body 2, and the connecting block 3 is also Made of plastic. The plastic part is provided with a plurality of circular buffer holes, the inner ring body 1 and the outer ring body 2 are longitudinally cut into an insertion port 5 for installation, and the walls of the inner ring body 1 and the outer ring body 2 are both provided with Multiple buffer holes4. Two upper and lower grooves 6 are formed between the inner ring body 1 and the outer ring body 2 at positions outside the connecting block 3. The upper and lower edges of the inner ring body 1 and the outer ring body 2 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com