Control method of sewing machine

A control method and sewing machine technology, which is applied to sewing machine components, program-controlled sewing machines, sewing equipment, etc., can solve the problems of wasting time and restricting work efficiency, and achieve the effect of improving sewing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

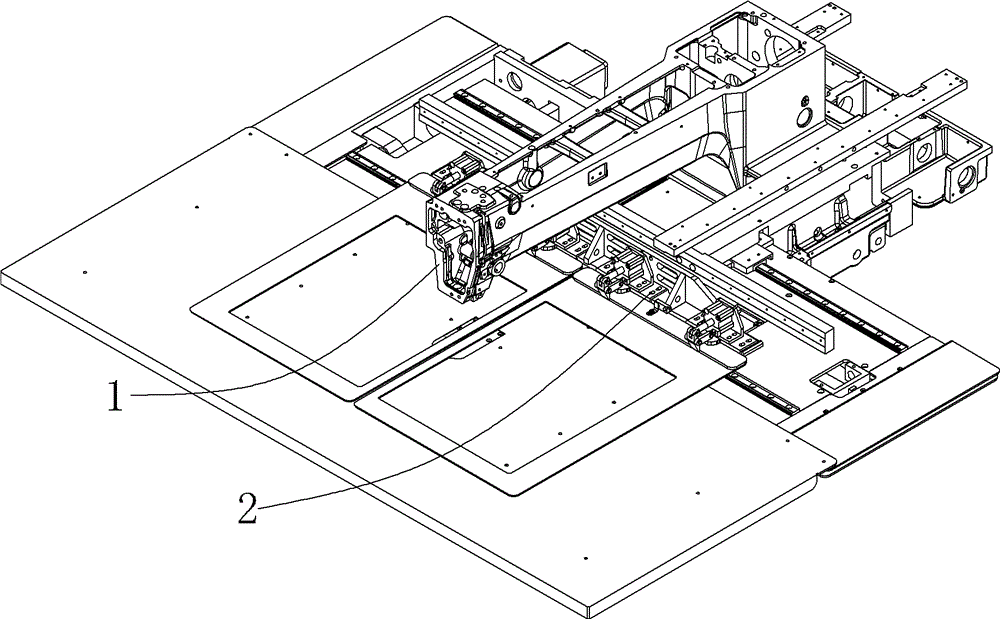

[0031] Such as figure 1 As shown, the sewing machine of the present invention includes a sewing machine head 1, an XY feeding mechanism and a control system. Machine head 1 and XY feeding mechanism can adopt existing known structure. The control system includes power supply, motherboard, processor, memory and system software.

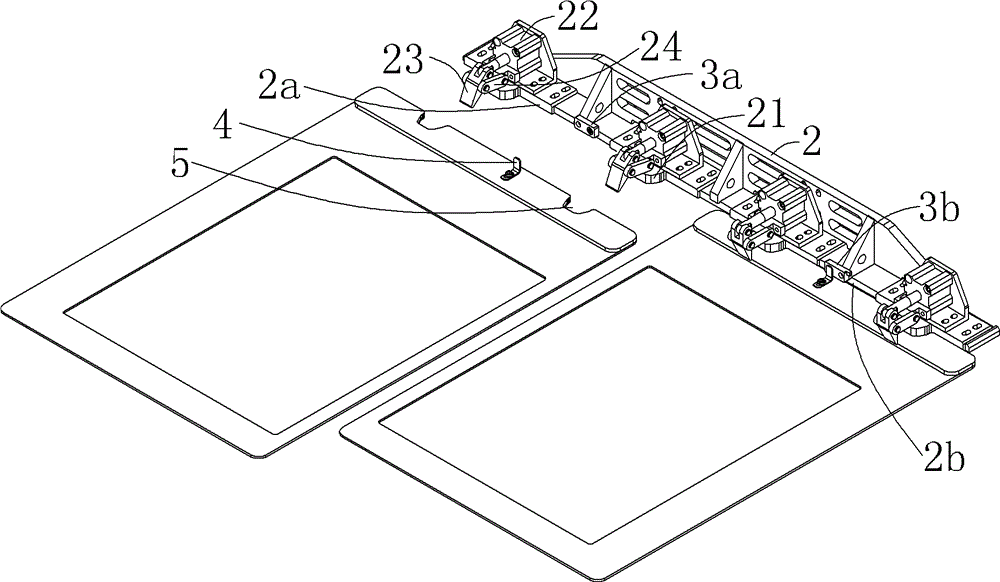

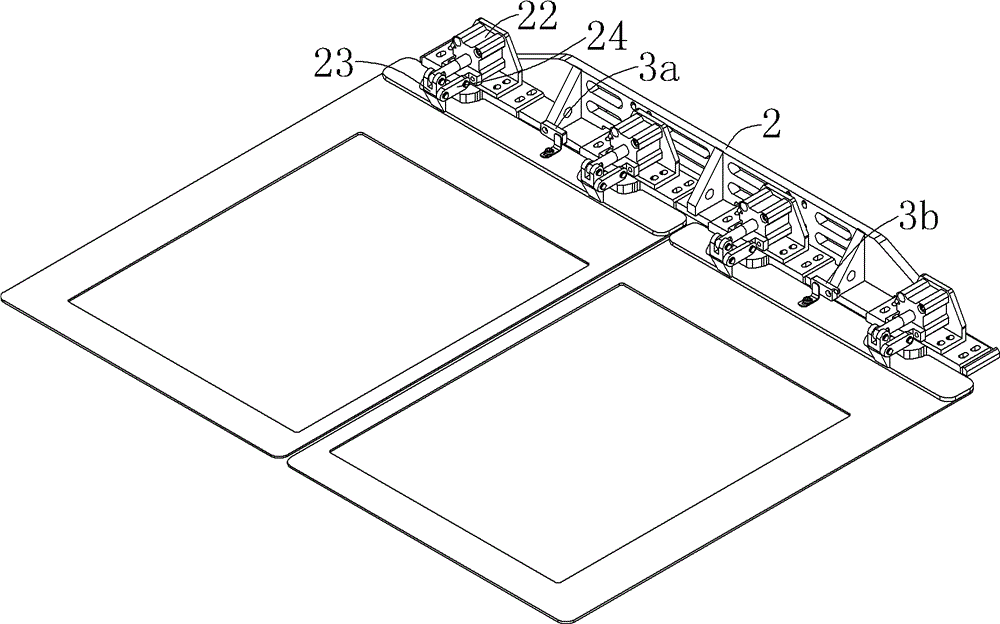

[0032] The XY feeding mechanism is provided with a feeding base 2 for installing templates. Driven by the XY feeding mechanism, the feeding base 2 can move in the X direction and the Y direction of the workbench horizontal plane coordinate system.

[0033] The feeding base 2 can be provided with 2, 3 or more template mounting positions. The formwork installation position is the area on the feeding base 2 that is docked with the formwork. The feeding base 2 has several formwork installation positions, and several formworks can be docked and installed at the same time.

[0034] In this embodiment, as a preferred solution, the feeding base 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com