A sewing machine with easy template replacement

A sewing machine, easy-to-replace technology, applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of restricting operation efficiency and wasted time, and achieve the effect of improving sewing efficiency and saving operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

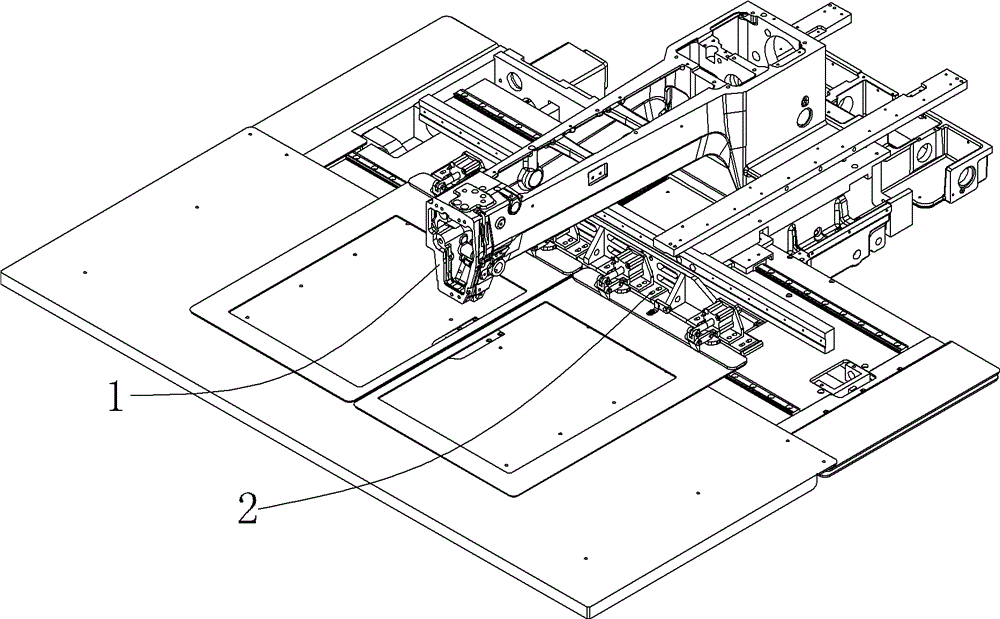

[0032] Such as figure 1 As shown, the sewing machine of the present invention includes a sewing machine head 1, an XY feeding mechanism and a control system. Machine head 1 and XY feeding mechanism can adopt existing known structure. The control system includes power supply, motherboard, processor, memory and system software.

[0033] The XY feeding mechanism is provided with a feeding base 2 for installing templates. Driven by the XY feeding mechanism, the feeding base 2 can move in the X direction and the Y direction of the workbench horizontal plane coordinate system.

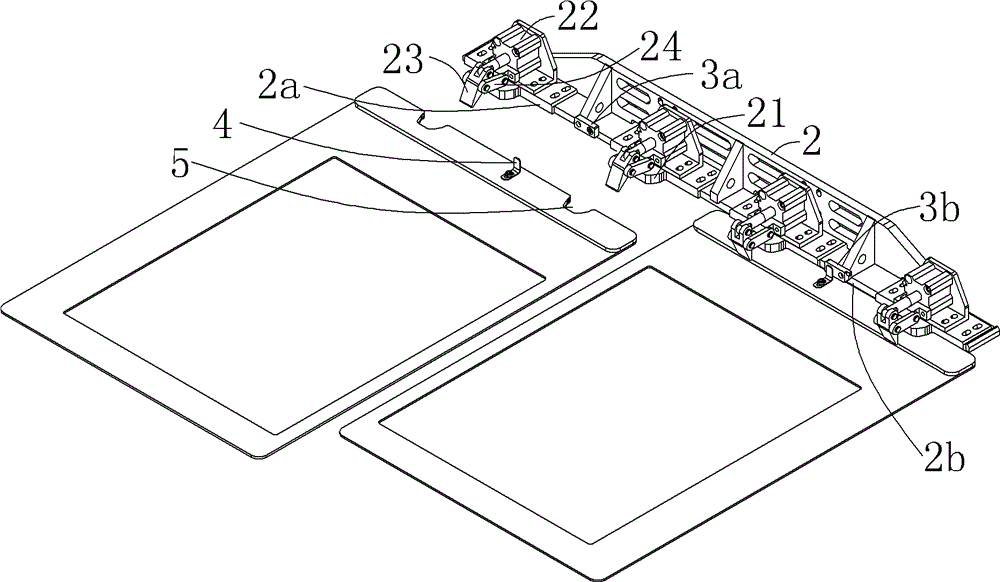

[0034] The feeding base 2 can be provided with 2, 3 or more template mounting positions. The formwork installation position is the area on the feeding base 2 that is docked with the formwork. The feeding base 2 has several formwork installation positions, and several formworks can be docked and installed at the same time.

[0035] In this embodiment, as a preferred solution, the feeding base 2 is provid...

Embodiment 2

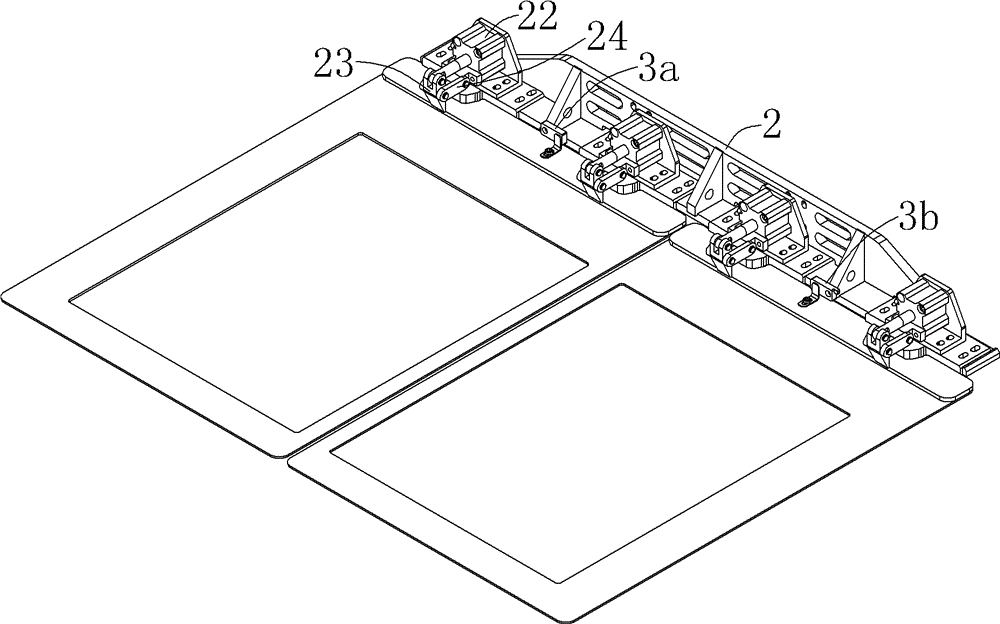

[0061] Such as Figure 4 and Figure 5 As shown, in this embodiment, the feeding base 2 has one template installation position, and only one template can be installed at most. The feeding base 2 is provided with a sensor for detecting whether there is a template, a fixing mechanism for locking the template, and a positioning structure that can cooperate with the template. The fixing mechanism and positioning structure can adopt the structure in Embodiment 1.

[0062] When the template is installed in the template installation position, the sensor can sense and detect it, and send a detection signal to the control system.

[0063] When the installation groove 5 on the formwork is aligned with the positioning structure of the formwork installation position and advanced, after the sensor senses that the formwork is in place, the control system controls the fixing mechanism to lock the placed formwork.

[0064] Under the control of the control system, the XY feeding mechanism m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com