Device and method for arranging special-shaped fireworks cartridges

A technology of special-shaped arrangement and fireworks cartridges, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of low production efficiency, high labor intensity in the arrangement process, and can not meet the production demand, so as to achieve high safety and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

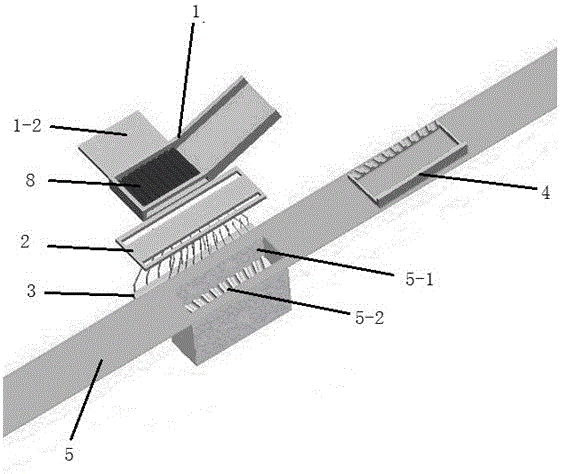

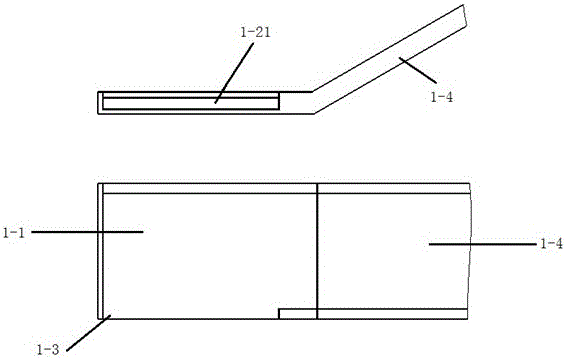

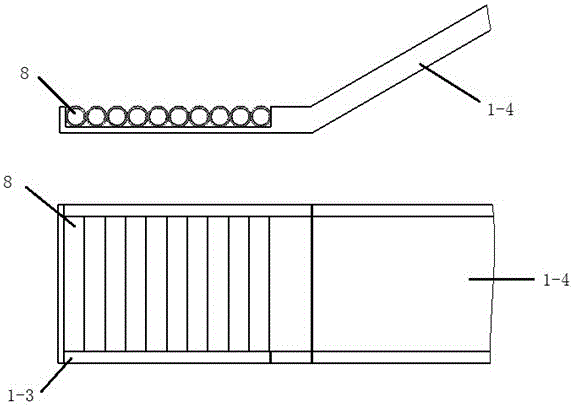

[0038]The quantity of each group of cartridges 8 is 11, the length of each cartridge is 50cm, and the diameter is 10cm; the length of the cartridge groove 1-1 is 110cm, and the width is 50cm; the length of the cartridge channel 1-3 is 110cm; the push plate through hole Long 110cm, high 6cm; The thickness of push plate 1-2 is 6cm.

[0039] The length of the arrangement plate 2 is 160cm, the width is 50cm, and the thickness is 10cm; the length of the arrangement fork channel 2-1 is 150cm, and the distance from the arrangement fork channel 2-1 to both sides is 7cm.

[0040] The distance between a pair of arrangement forks 3 is 36cm; the needle-shaped structures on each arrangement fork 3 are 12, and each needle-shaped structure is 30cm long. The distance between the needle-shaped structures was 10 cm.

[0041] The upper surface length of lifting formwork 5-2 is 140cm, and width is 45cm; The quantity of lifting formwork groove 5-3 is 11, and the included angle of each lifting for...

Embodiment 2

[0046] The quantity of each group of cartridges 8 is 11, the length of each cartridge is 50cm, and the diameter is 10cm; the length of the cartridge groove 1-1 is 110cm, and the width is 50cm; the length of the cartridge channel 1-3 is 110cm; the push plate through hole Long 110cm, high 6cm; The thickness of push plate 1-2 is 6cm.

[0047] The length of the arrangement plate 2 is 160cm, the width is 50cm, and the thickness is 10cm; the length of the arrangement fork channel 2-1 is 150cm, and the distance from the arrangement fork channel 2-1 to both sides is 7cm.

[0048] The distance between a pair of arrangement forks 3 is 36cm; the needle-shaped structures on each arrangement fork 3 are 12, and each needle-shaped structure is 30cm long. The distance between the needle-shaped structures was 10 cm.

[0049] The upper surface length of lifting formwork 5-2 is 140cm, and width is 45cm; The quantity of lifting formwork groove 5-3 is 11, and the included angle of each lifting fo...

Embodiment 3

[0054] The quantity of each group of cartridges 8 is 11, the length of each cartridge is 50cm, and the diameter is 10cm; the length of the cartridge groove 1-1 is 110cm, and the width is 50cm; the length of the cartridge channel 1-3 is 110cm; the push plate through hole Long 110cm, high 6cm; The thickness of push plate 1-2 is 6cm.

[0055] The length of the arrangement plate 2 is 160cm, the width is 50cm, and the thickness is 10cm; the length of the arrangement fork channel 2-1 is 150cm, and the distance from the arrangement fork channel 2-1 to both sides is 7cm.

[0056] The distance between a pair of arrangement forks 3 is 36cm; the needle-shaped structures on each arrangement fork 3 are 12, and each needle-shaped structure is 30cm long. The distance between the needle-shaped structures was 10 cm.

[0057] The upper surface length of lifting formwork 5-2 is 140cm, and width is 45cm; The quantity of lifting formwork groove 5-3 is 11, and the included angle of each lifting fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com