A kind of modified activated carbon adsorbent and preparation method thereof

A technology of activated carbon adsorption and coconut shell activated carbon, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of limited adsorption capacity of adsorbents, and achieve the effects of excellent adsorption, wide source of raw materials, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

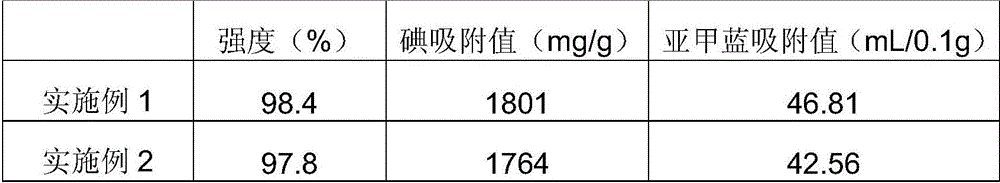

Examples

Embodiment 1

[0021] A modified activated carbon adsorbent, in parts by weight, its composition raw materials include: 400 parts of coconut shell activated carbon, 400 parts of coal-based activated carbon, 400 parts of wood activated carbon, 65 parts of bentonite, 38 parts of coal tar and 5 parts of methyl cellulose share. The modified activated carbon adsorbent is prepared according to the following steps:

[0022] Step 1, pulverizing bentonite and calcining in a calcination furnace at 600°C for 4 hours;

[0023] Step 2, take out the calcined bentonite, add coconut shell activated carbon, coal-based activated carbon, wood activated carbon, coal tar and water, adjust it into mud, heat it to 70°C and grind it for 3 hours to get a 200-300 mesh slurry, and dry it;

[0024] Step 3: Spray an aqueous solution of methyl cellulose to the particles obtained in step 2, heat the particles to wrap a layer of methyl cellulose film, and dry them.

Embodiment 2-7、 comparative example 1-9

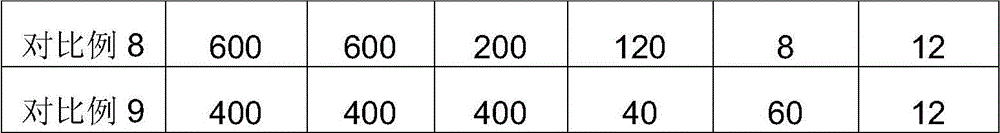

[0026] The difference between Examples 2-6 and Comparative Examples 1-3 and Example 1 lies in the composition ratio of raw materials, see Table 1 for details.

[0027] Table 1 Raw material composition ratio of Examples 2-6 and Comparative Examples 1-3 (unit: parts by weight)

[0028]

[0029]

Embodiment 8

[0031] The difference between this example and Example 1 lies in: step 1, the bentonite is pulverized and calcined in a calcination furnace at 550° C. for 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com