Wiring device between motor and controller

A wiring device and controller technology, which is applied in the direction of conductive connection, circuit, connection, etc., can solve the problems of damage to the MOS tube of the controller, easy loosening of the conductive ring, and threats to personal safety, so as to achieve clean wiring, avoid electric sparks, and improve The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific examples.

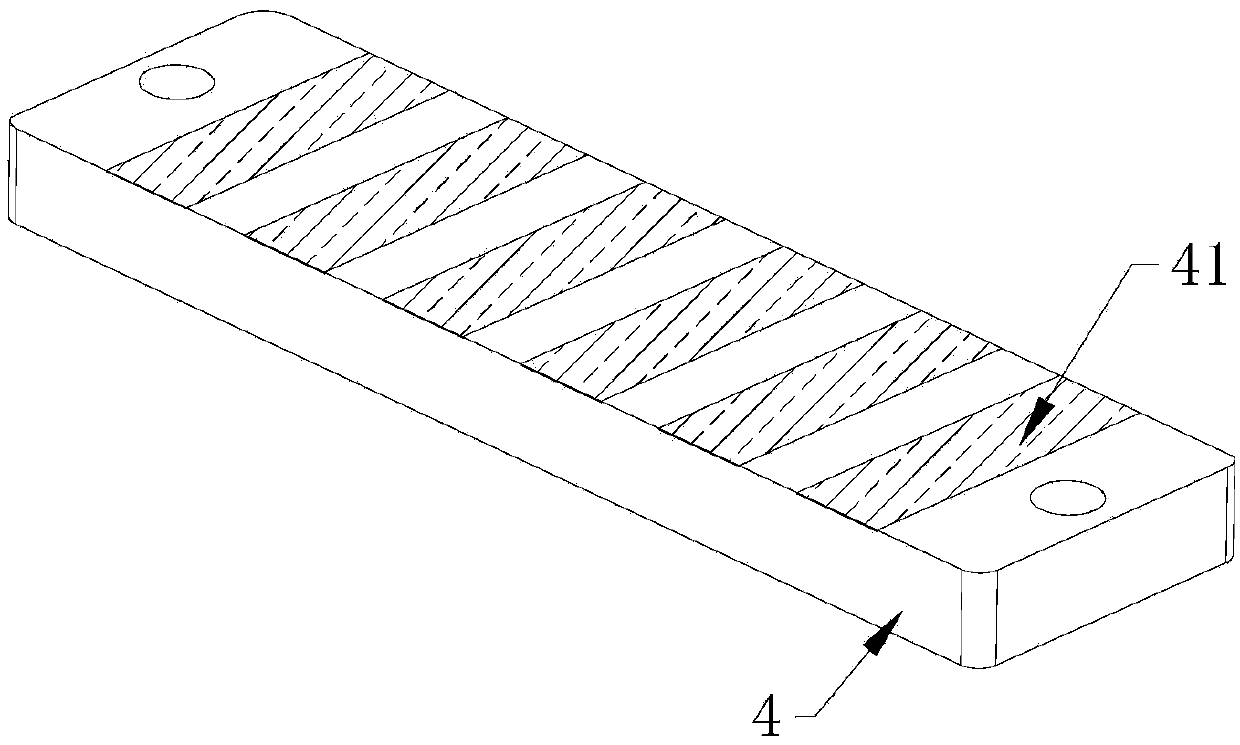

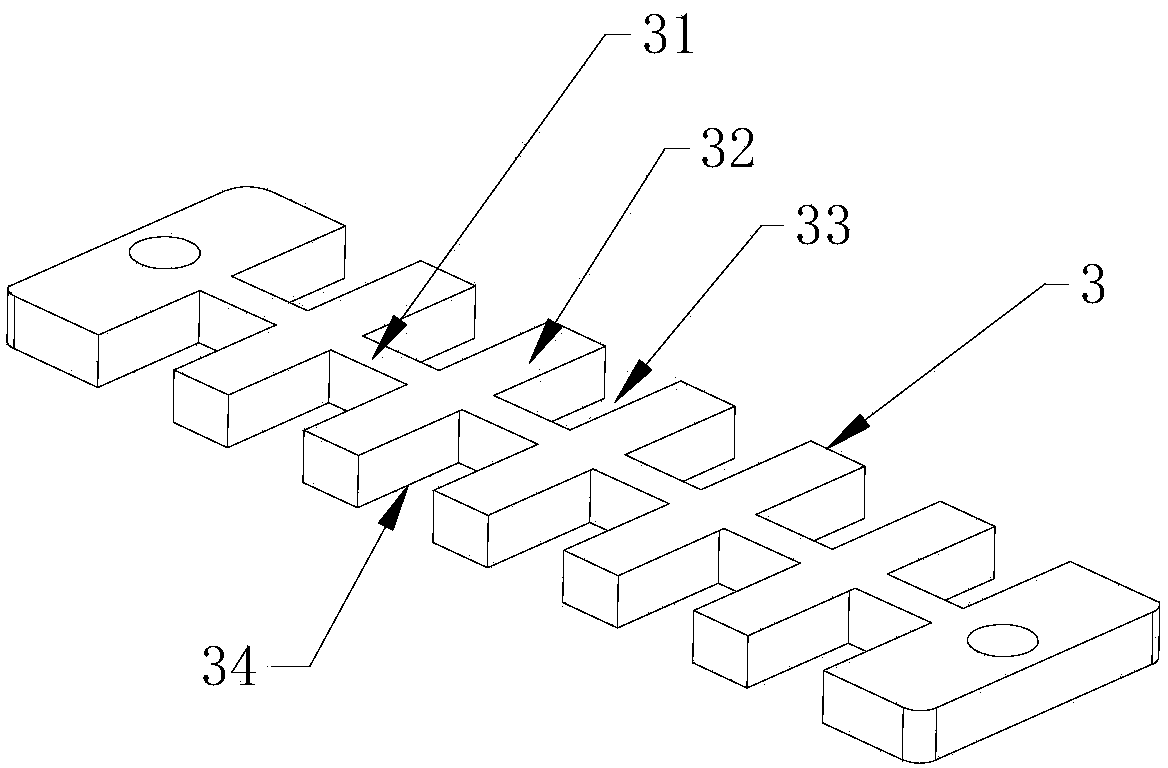

[0022] Such as Figures 1 to 6 As shown, a wiring device for a motor and a controller includes a base 4, a ball receiving plate 3, a spring mounting plate 2, and an upper pressure plate 1 made of insulating materials, the base 4, the ball receiving plate 3, and a spring mounting plate 2. The upper pressing plate 1 is installed and fixed sequentially from bottom to top. The ball receiving plate 3 includes a plurality of placement grooves 34 for accommodating the balls 6, and a number of pressing grooves 33 that are equal in number to the placement grooves 34 and correspond one-to-one. The wire groove 33 and the placement groove 34 are all independent, and the ball receiving plate 3 includes a central skeleton rod 31 and several groove rods 32 arranged in parallel on both sides of the central skeleton rod 31, and the distance between each groove rod 32 constitutes the Describe th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com