Ground milling machine with means for locking milling roller box door in maintenance position

A locking device, milling machine technology, applied in the field of stabilizer or surface mining machine, road milling machine, repairing machine, can solve troublesome, impractical, close to walls, slopes or other corners, etc., to simplify the whole structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

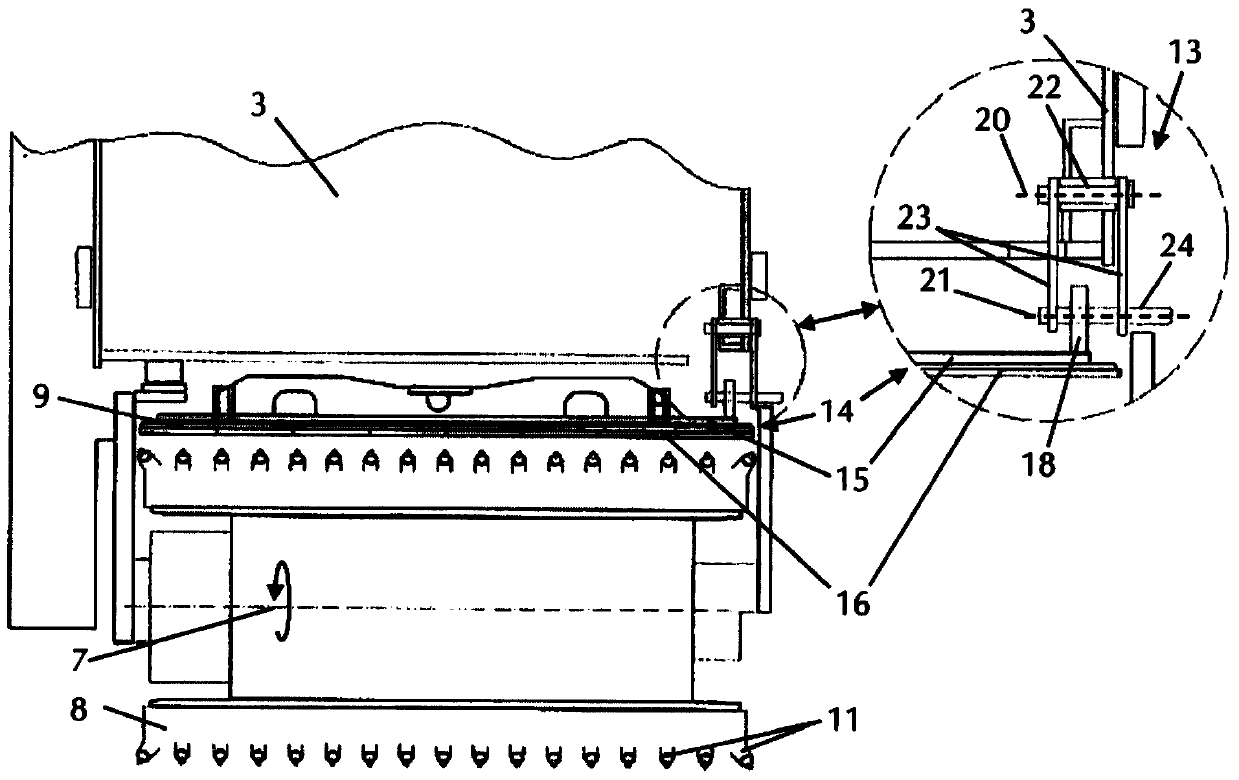

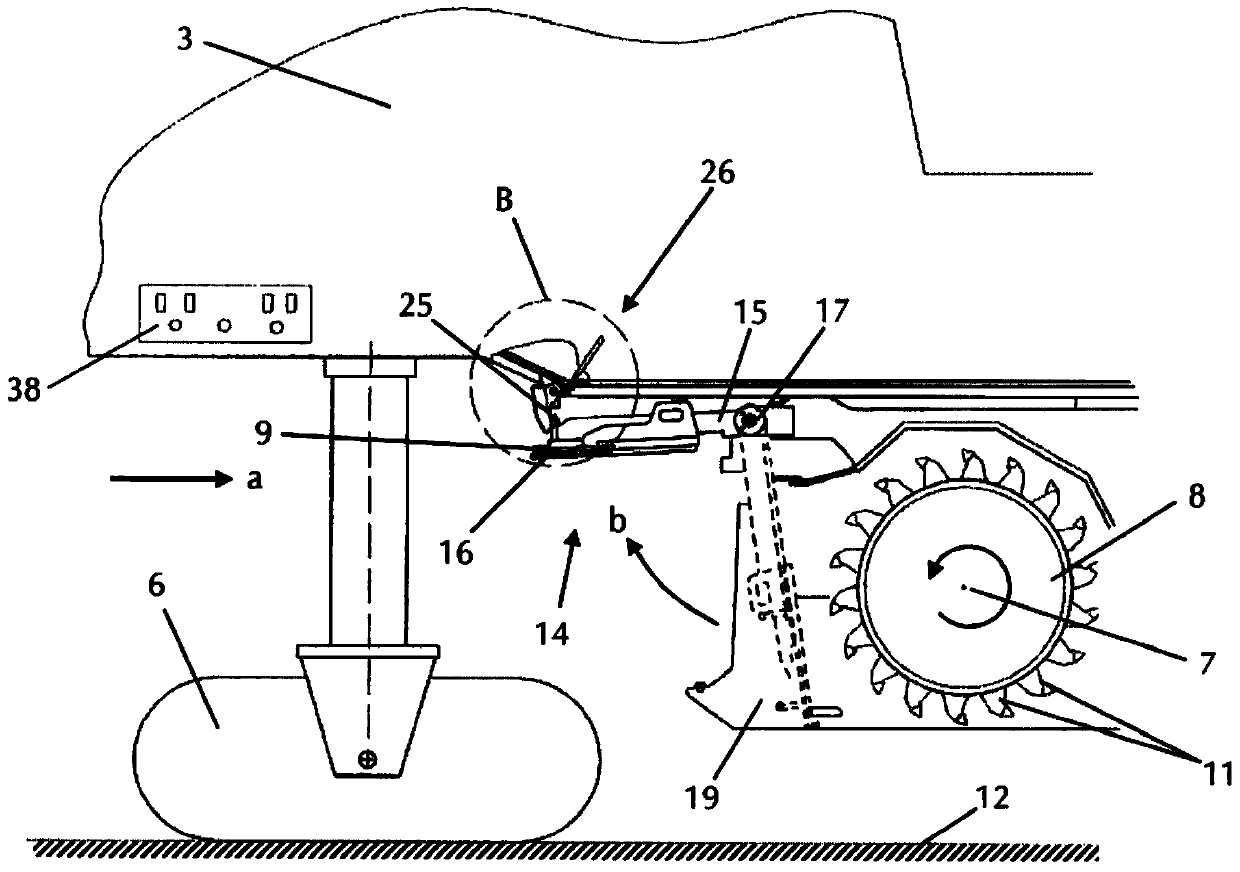

[0023] Identical or functionally identical components are marked with the same reference symbols in the figures, components which are repeated in individual figures are not individually marked in each figure.

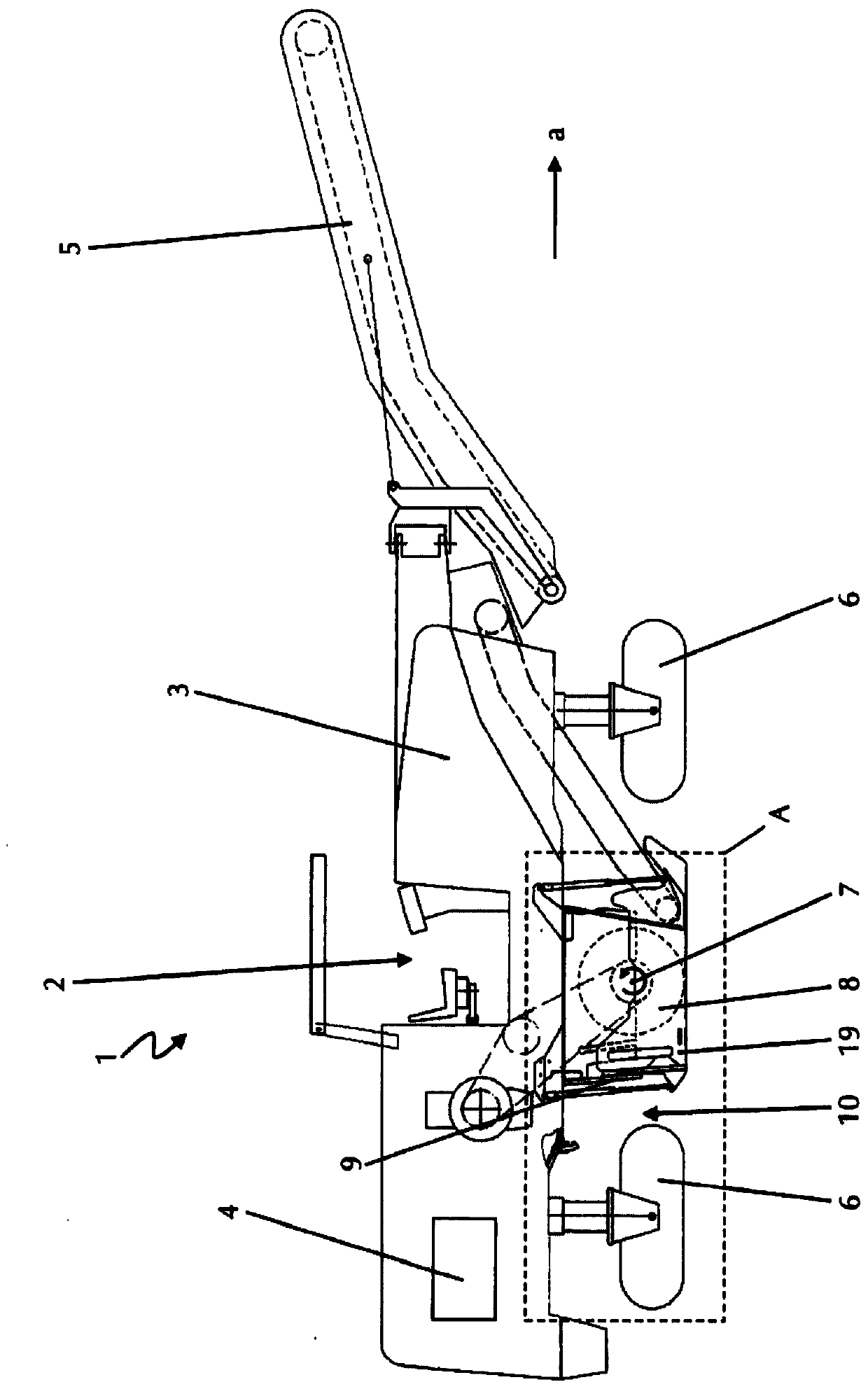

[0024] figure 1 A ground milling machine 1 of the type described is shown by way of example, in particular a road milling machine of the central rotor type. The road milling machine comprises a driving platform 2 , a frame 3 , a drive motor 4 , such as an internal combustion engine, a discharge belt 5 and crawlers 6 . The working device of the ground milling machine 1 comprises a milling roller 8 with an axis of rotation 7 , which is mounted in a milling roller housing 9 , which is closed off on the side facing the viewer by a side plate 19 . Behind the milling roller housing 9 in the working direction a there is a pivoting area 10 which will be explained in more detail below.

[0025] figure 2 The current state of the art is shown as a starting point for the invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com