Stirring impeller

A technology of stirring impeller and stirring blade, which is applied in the directions of mixer accessories, dissolving, mixer, etc., can solve the problems of laborious removal of blades, reduce work efficiency, increase labor intensity, etc., so as to reduce labor intensity, increase work efficiency and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

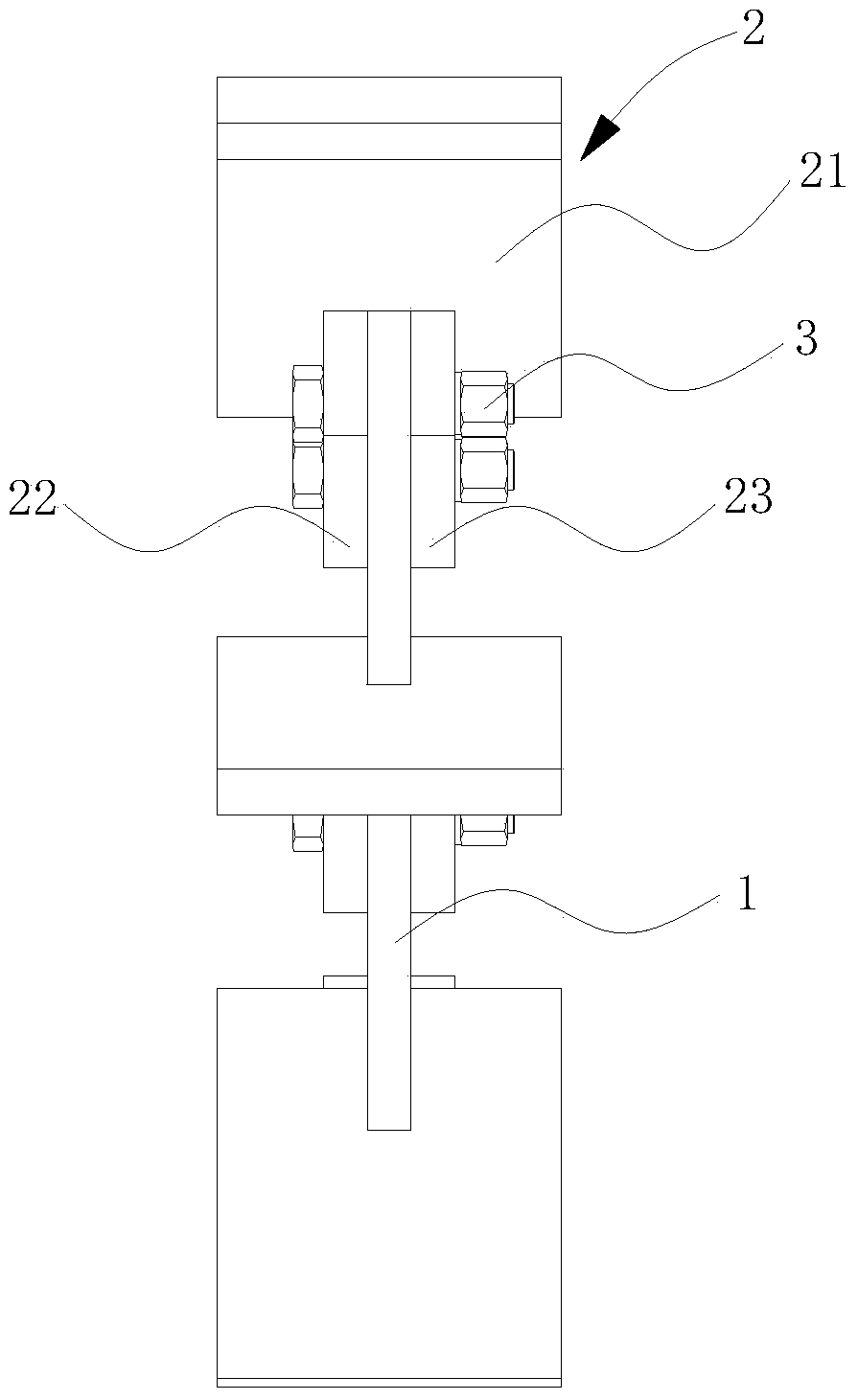

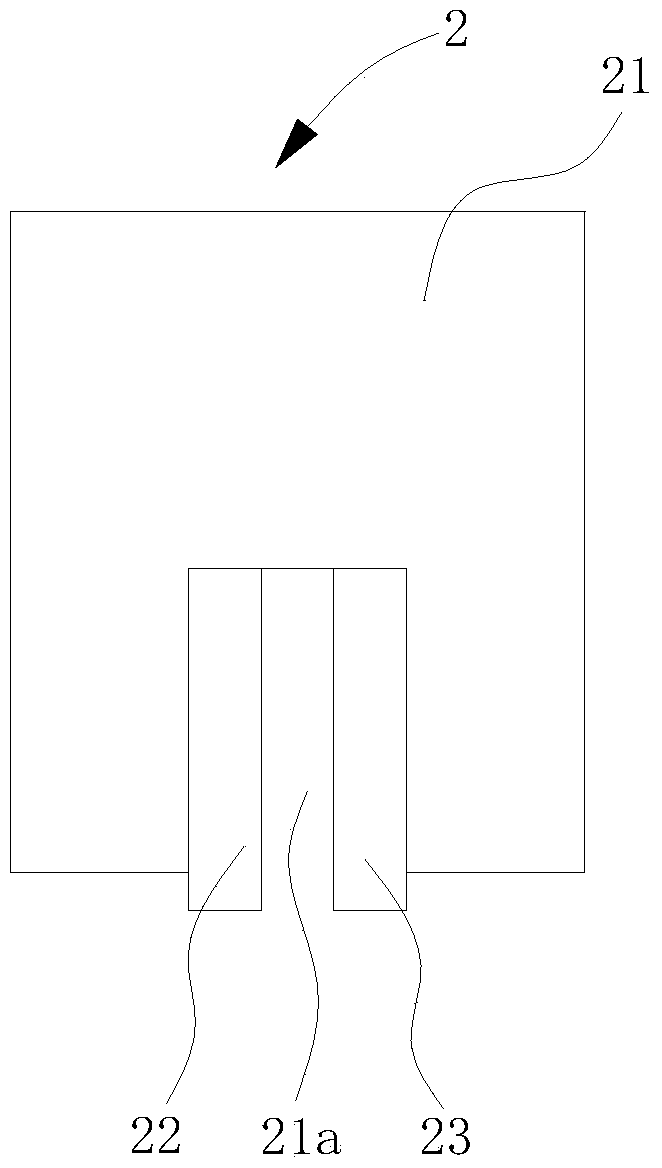

[0011] see figure 1 , 2 and 3.

[0012] The stirring blade provided by the present invention includes a wheel disc 1 and more than two stirring blades 2, the center of the wheel disc 1 is provided with an installation through hole 1a, and the periphery of the installation through hole 1a is provided with a number of fixed through holes 1b, and the two or more stirring blades 2 Evenly installed on the outer edge of the wheel disc 1, the stirring blade 2 includes a rectangular paddle 21, which has a strip-shaped through groove 21a with one end closed and the other end open. The center lines of the center lines are coaxial, the width of the strip-shaped through groove 21a corresponds to the thickness of the wheel disc 1, and the rectangular paddle 21 is provided with a first fixing plate 22 on the left side of the strip-shaped through groove 21a, and a second fixing plate on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com