Handheld seeder

A seeder and hand-held technology, applied in the direction of manual sowing tools, etc., can solve the problems of high cost, high sowing cost, and limited scope of application, and achieve the effects of expanding the scope of application, reducing the cost of sowing, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

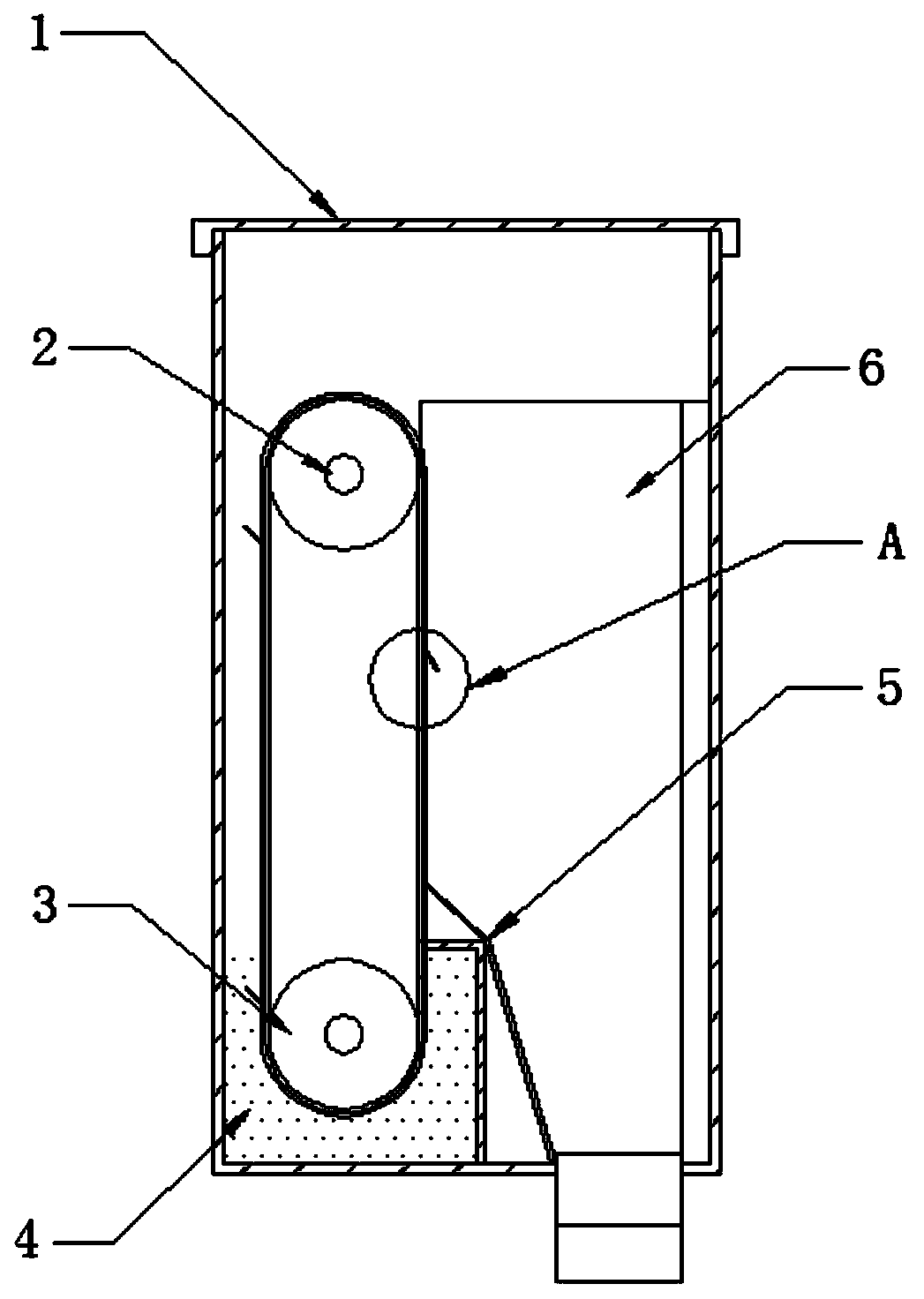

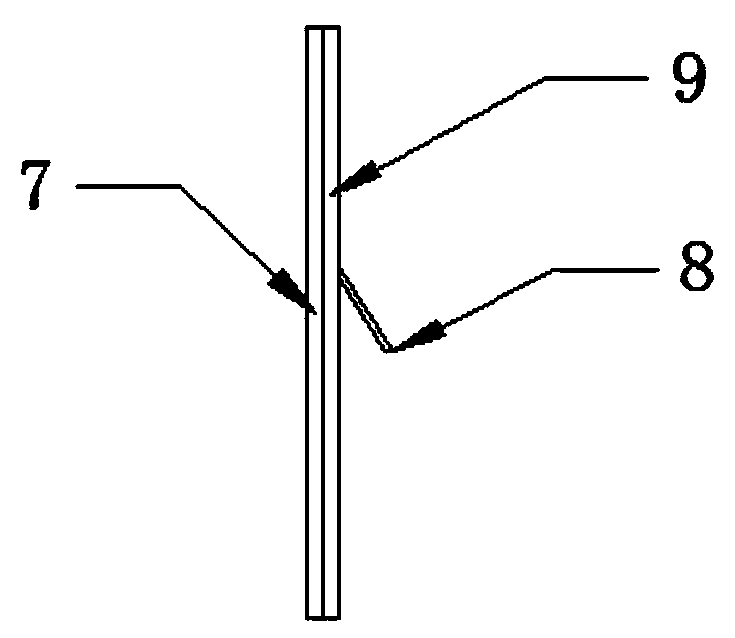

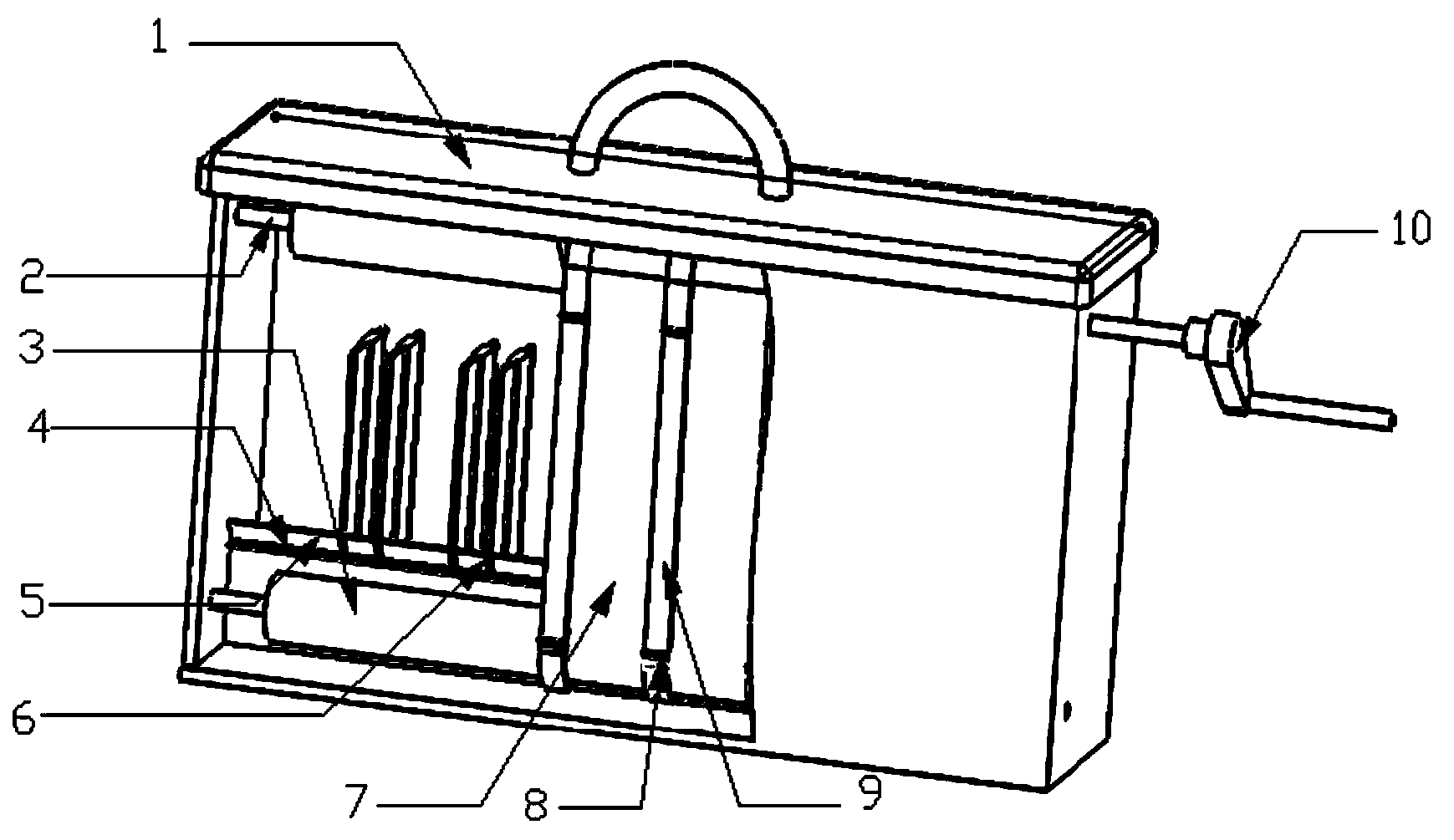

[0026] A handheld seeder such as Figure 1~3 Shown includes casing 1, seed box 4, driving shaft, driven shaft, belt 7, seeding belt 9, rocker 10, baffle plate 5 and partition 6; Set on the front side of the lower end of the inner shell 1; the driving shaft and the driven shaft are arranged on the inner front side of the shell 1 at intervals up and down, the driving shaft extends out of the shell 1, and is connected with the rocker 10, and the driven shaft is located inside the seed box 4; The shaft has the same structure as the driven shaft, and is composed of a support shaft 2 and a sprocket 3 sleeved on the support shaft 2, and the support shaft 2 and the sprocket 3 are connected by a key. The support shaft 2 is fixed on the shell through bearings, and the rocking bar 10 is connected with the support shaft 2 on the drive shaft, and the belt 7 is looped between the two sprockets 3 . The supporting shaft 2 and the sprocket 3 are made of metal materials. The length of the sup...

Embodiment 2

[0031] The difference with Embodiment 1 is that in the present embodiment, the belt 7 is provided with 910 seeding belts arranged in parallel vertically, such as Figure 5 As shown, in the present embodiment, the size of the plug tray sown is 10 × 20, and the distance between the centers of the seeding belts 9 is 2.6 centimeters. During actual use, the number of single sowings can be adjusted according to the size of the sown tray, the number of the seeding belts 9 and the spacing between the seeding belts 9, and the size of the seeding belts 9 can be adjusted according to the size of the sown seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com