Vertical oil storage device for transformer

A transformer and vertical technology, applied in the field of vertical oil storage equipment for transformers, can solve the problems affecting the normal expansion and contraction of metal bellows, affecting the normal operation of the transformer, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

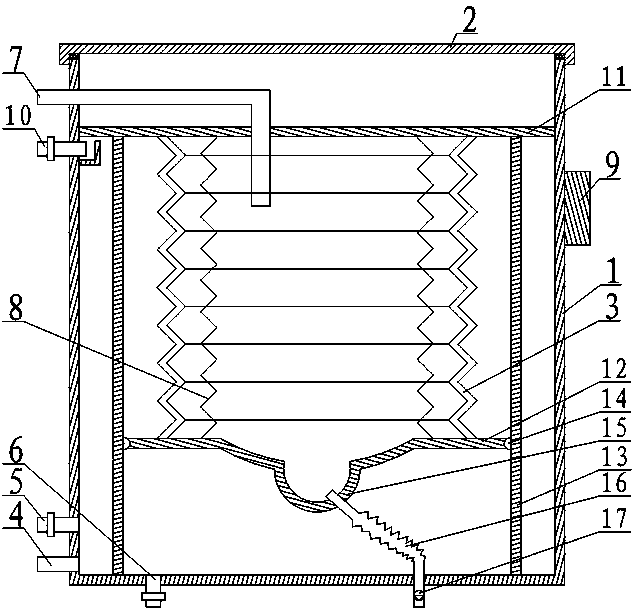

[0016] Such as figure 1 As shown, the vertical oil storage equipment for transformers includes a housing 1, a cover 2, a metal bellows 3, an elastic expansion member 8, an oil level gauge 9 and a drain pipe 16, wherein the housing 1 constitutes a barrel with an open upper end shape, the cover 2 is connected with the housing 1 and closes the upper opening of the housing 1 , and the oil level gauge 9 is arranged on the housing 1 . The metal bellows 3 is vertically arranged in the housing 1, the upper end of the metal bellows 3 is connected with an upper connecting plate 11 closing its upper opening, the lower end of the metal bellows 3 is connected with a lower connecting plate 12 closing its lower opening, and the upper connecting plate 11 Periphery is sealed and fixed on the inner wall of the housing 1. The central part of the lower connecting plate 12 is concave to form a water storage tank 15. The water storage tank 15 opens upward and is hemispherical in shape. One end of t...

Embodiment 2

[0019] This embodiment makes the following further limitations on the basis of Embodiment 1: the lower connecting plate 12 of this embodiment is formed with a cylindrical transition section with a large upper part and a smaller lower part, wherein the cylindrical transitional section is defined by the water tank 15 The edge spreads to the water tank 15 peripheral areas. In this embodiment, under the transition action of the cylindrical transition section, it is possible to avoid loud noises when the water in the metal bellows 3 flows to the water storage tank 15 .

Embodiment 3

[0021] In order to prevent the metal bellows 3 from shifting, twisting or deforming when it expands and contracts, this embodiment makes the following further limitations on the basis of Embodiment 1 or Embodiment 2: This embodiment also includes a plurality of vertically arranged guide rails 13 , wherein, the upper and lower ends of the guide rail 13 are respectively connected with the lower end surface of the upper connecting plate 11 and the upper end surface of the lower connecting plate 12, and the lower connecting plate 12 is connected with the rollers 14 embedded in the guide rail 13 which are equivalent in number and position one-to-one with the guide rail 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com